- Protect pumps and other critical equipment from costly clogs and damage from tough solids

- Wipes Ready™ cutters prevent materials from forming long strips and reweaving in the waste stream

- No labor needed to clean, disassemble and reassemble the repair unit, or wait months for parts. Just swap and go!

- Delta P side rails ensure solids are processed by the dual-shafted grinder while optimizing flow through the unit

- Lower operating costs by keeping pumps and other equipment running efficiently

Muffin Monster™ inline/open channel grinders

Monsters keep wipes away

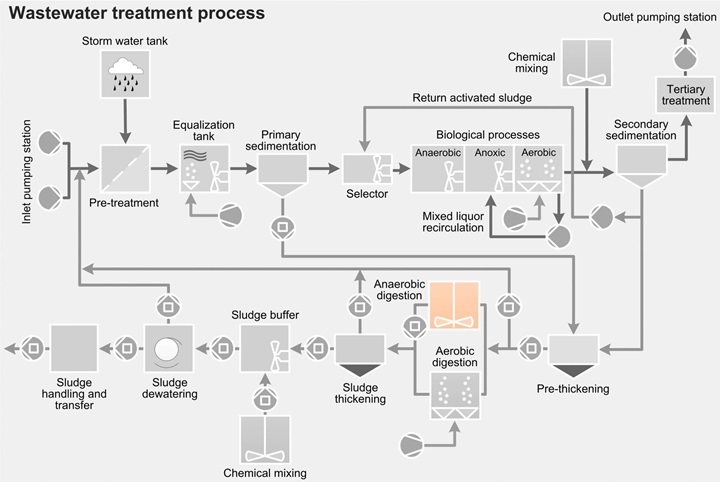

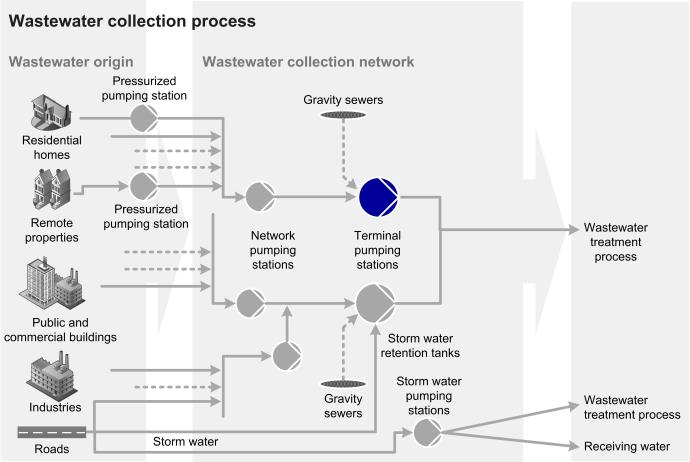

- Sewage pump stations

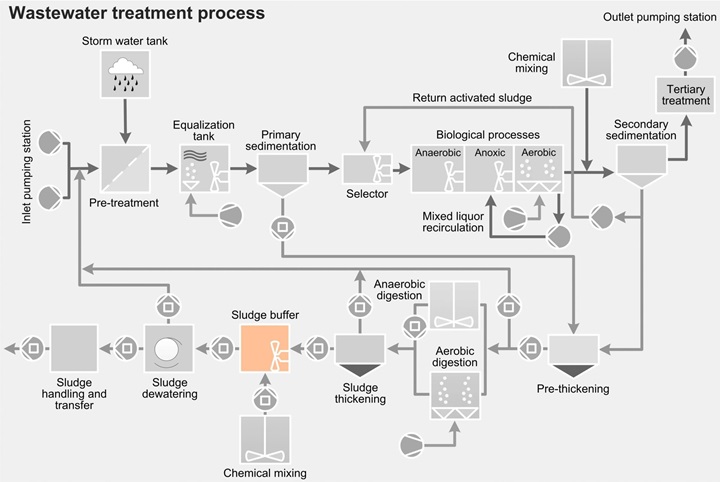

- Headworks – primary treatment

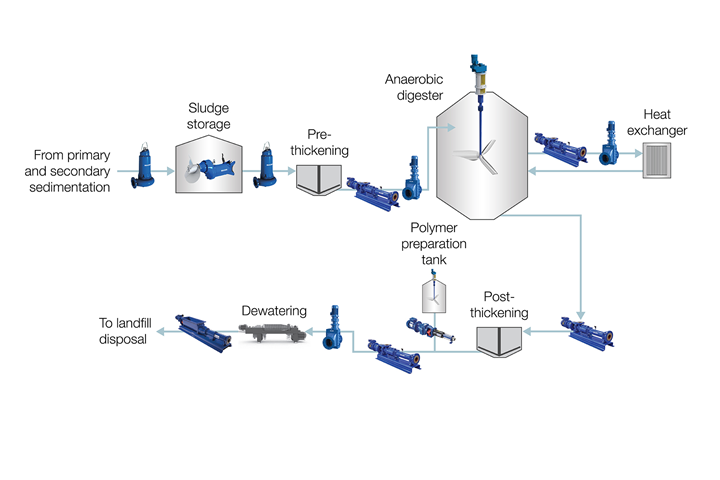

- Sludge processing

- Anaerobic digestion / Bioresource

- Septage / Grease receiving

- Correctional facilities

- Airports

- Facilities management

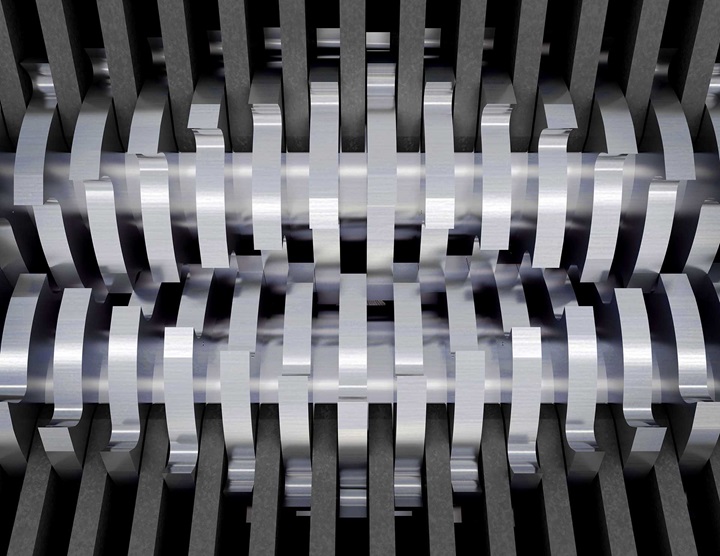

- Dual-shafted, high-torque grinders handle rags, rocks, woods, wipes, clothing, plastics and other debris

- Wipes Ready™ cutters create two-dimensional cutting capabilities to control width and length of output

- In-line 30K Muffin Monster includes an easy-to-remove cutter cartridge

- Patented Delta P side rails drive debris into the cutters

- Grinders reduce solids to a size that pumps and other equipment can process efficiently and safely

- Housings: ductile iron

- Cutters: hardened alloy steel

- Shafts: hardened alloy steel

- Mechanical seals: tungsten carbide faces

The 10K Series Muffin Monster is a compact grinder, tough on solids in sludge and sewage applications. It fits into areas with limited space, while still providing the necessary power for downstream protection. The 10K Series is an ideal, low-cost solution that goes beyond sludge grinding at resource recovery facilities. It fits perfectly into office buildings, apartment complexes, resorts, retail centers and package treatment plants.

- Hex shafts: 50 mm

- Motor: Standard 1.5 kW; 25:1 reducer

- Cutter size: 120 mm diameter

- Seal max working pressure: 6 bar (optional severe-duty seals available)

Inline model

| Inline model |

Flow rate (1) m3/hr |

Pipeline size mm | Pressure drop bar |

| 10000-B100-DI | 62 | 100 | 0.03 |

| 10000-B150-DI | 125 | 150 | 0.09 |

Open channel model

| Open channel model | Flow rate (2) m3/hr | Head drop mm |

| 10002-0008-DI | 41.4 |

146 |

Troublesome solids are now easier than ever to reduce with the Muffin Monster dual-shafted grinder. Its slow-speed, high-torque design shreds tough solids that typically cause sewer problems. The 30K Muffin Monster is available as both inline and open channel configurations.

- Hex shafts: 50 mm

- Motor: Standard 2.2 kW; 25:1 reducer

- Cutter size: 120 mm diameter

- Seal max dry working pressure: 10.3 bar

Inline model

| Inline model | Flow rate (1) m3/hr | Pipeline size mm | Pressure drop bar |

| 30004T-B100 | 102 | 100 | 0.04 |

| 30004T-B150 | 159 | 150 | 0.08 |

| 30004T-B200 | 250 | 200 | 0.21 |

| 30004T-B250 | 386 | 250 | 0.20 |

| 30004T-B300 | 556 | 300 |

0.40 |

Open channel model

| Open channel model | Flow rate (2) m3/hr | Head drop mm |

| 30005-0008 | 84 | 178 |

| 30005-0012 | 141 | 290 |

| 30005-0018 | 223 | 405 |

| 30005-0024 | 311 |

405 |

| 30005-0032 | 477 | 445 |

| 30005-0040 | 686 | 495 |

| 30005-0050 | 979 | 595 |

| 30005-0060 |

1'277 |

760 |

The 40K Series Muffin Monster excels in wet and dry grinding applications. It is a powerful shredder for large processing systems. It also serves in many industrial applications, including fish and beef processing, petroleum, pulp and paper mills, chemical plants, and recycling plants.

- Hex shafts: 64 mm

- Motor: Standard 7.5 kW; 35:1 reducer

- Cutter size: 191 mm diameter

- Seal max dry working pressure: 10.3 bar

Inline model

| Inline model | Flow rate (1) m3/hr | Pipeline size mm | Pressure drop bar |

| 40002-18B300 |

612 |

300 | 0.24 |

| 40002-24B400 | 999 | 400 | 0.15 |

| 40002-24B450 | 1'249 | 450 |

0.23 |

| 40002-32B500 | 1'558 | 500 | 0.29 |

Open channel model

| Open channel model | Flow rate (2) m3/hr | Head drop bar |

| 40002-0018 | 207 |

203 |

| 40002-0024 | 327 |

406 |

| 40002-0032 | 477 | 457 |

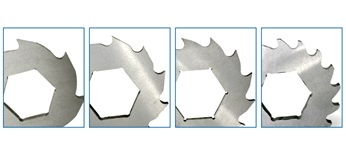

Cutters

- 7,11,13 and 17* tooth options

* Wipes Ready™ serrated cutters - Cutter stack can be tailored to meet operational requirements

- Available in optional stainless steel for 7, 11 and 13 tooth cutters

Motors

- IP55 TEFC Motor, standard

- IP55 TEFC Motor for ATEX: (Ex d IIC T4), optional

- IP68 Immersible Motor ATEX: (Ex de IIB T4), optional

- IP55 Integrated drive, 10K only

- Extended drive shafts available

Smart controller

- Load-sensing control system automatically reverses to clear jams

- Powder-coated mild steel or stainless steel IP65 enclosures

Custom frames

- Stainless steel frames for easy installation

|

10000 inline Muffin Monster |

10002 open channel Muffin Monster |

30004T inline Muffin Monster |

30005 open channel Muffin Monster |

|

| 17 tooth Wipes Ready cutters |

Optional |

Optional | Optional | Optional |

| Delta P side rails | Yes | |||

| Optimized cut control | Yes | Yes | Yes | Yes |

Wipes Ready Technology

Muffin Monster sewage grinders are available with the unique, Wipes Ready technology. It is designed to capture all wipes in the waste stream and shred them into small pieces that will not reweave to form ropes and ragballs in sewage systems.

The Wipes Ready technology applied in Muffin Monster sewage grinders includes:

- Wipes Ready cutters – A combination of serrated cutters and knurled spacers cuts wipes in two directions. The result is smaller particles that cannot reweave downstream.

- Delta P side rails – Direct solids into the cutters without sacrificing flow rate and prevent debris build-up in the grinder

- Optimized cut control (OCC) – The OCC gear ratio optimizes shaft speeds to enhance the cutting action and cleaning of the cutters, which in turn improves the performance and life of the grinder.

Please note that different Muffin Monster models feature different Wipes Ready options.