- Heavy-duty engineered pumps tailored to process requirements

- Designed and built following API 610 (ISO 13709) and associated international standards

- High efficiency performance for best total life time cost

- Specifically designed for circulation of slurry with large free passage between two adjacent blades

- Robust design for long Mean Time Between Maintenance (MTBM)

- Direct mounted or with sprung baseplate to accommodate thermal expansion of loop reactor vessel

AH axial flow pump

Loop reactor circulation pump for very high pressure applications

The Sulzer Ensival Moret model AH high pressure loop reactor circulation pumps are specifically designed for the circulation of polyethylene and polypropylene slurry. Operation of the reactor loop for extended periods helps boost productivity. It is not uncommon to find model AH pumps running more than 5 years between overhauls.

- Polyolefins industry

- Slurry phase polypropylene (PP)

- Slurry phase polyethylene (PE)

Main design features

- Large shaft which to minimize deflection for maximum seal life

- Double or Triple Mechanical Seal Arrangement to suit pump configuration

- All mechanical seals are designed to handle the maximum system pressure in the event of primary seal failure

- API Seal Support Systems ensure correct seal face lubrication and cooling

- Robust tilting pad thrust bearing with integrated heat exchanger on sizes above 12” to ensure maximum reliability

Key characteristics

| Capacities | Up to 18,000 m3/h / 80,000 US gpm |

| Heads | Up to 45 m / 150 ft |

| Pressures | Up to 100 bar / 1,500 psi |

| Temperatures | Up to 200°C / 400°F |

| Discharge size | 150 to 710 mm / 6 to 28 inches |

| Maximum speed of rotation | To suit application |

Performance range

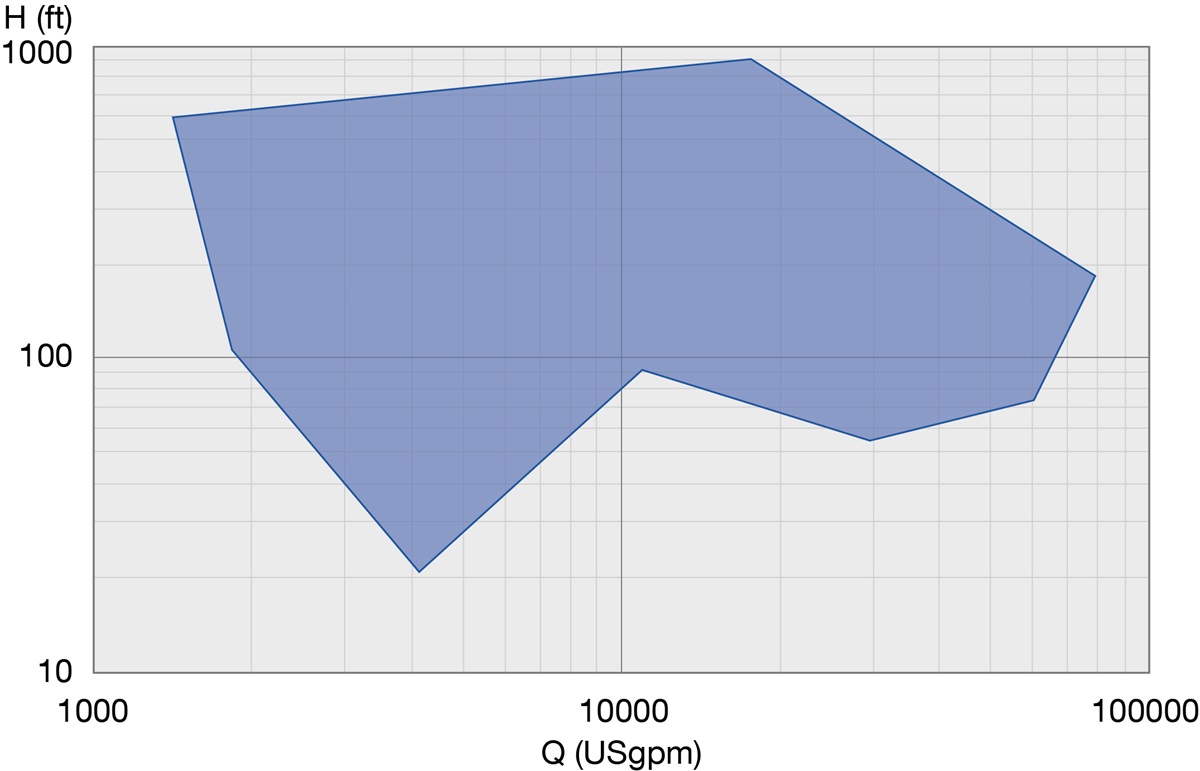

Performance Range 60 Hz

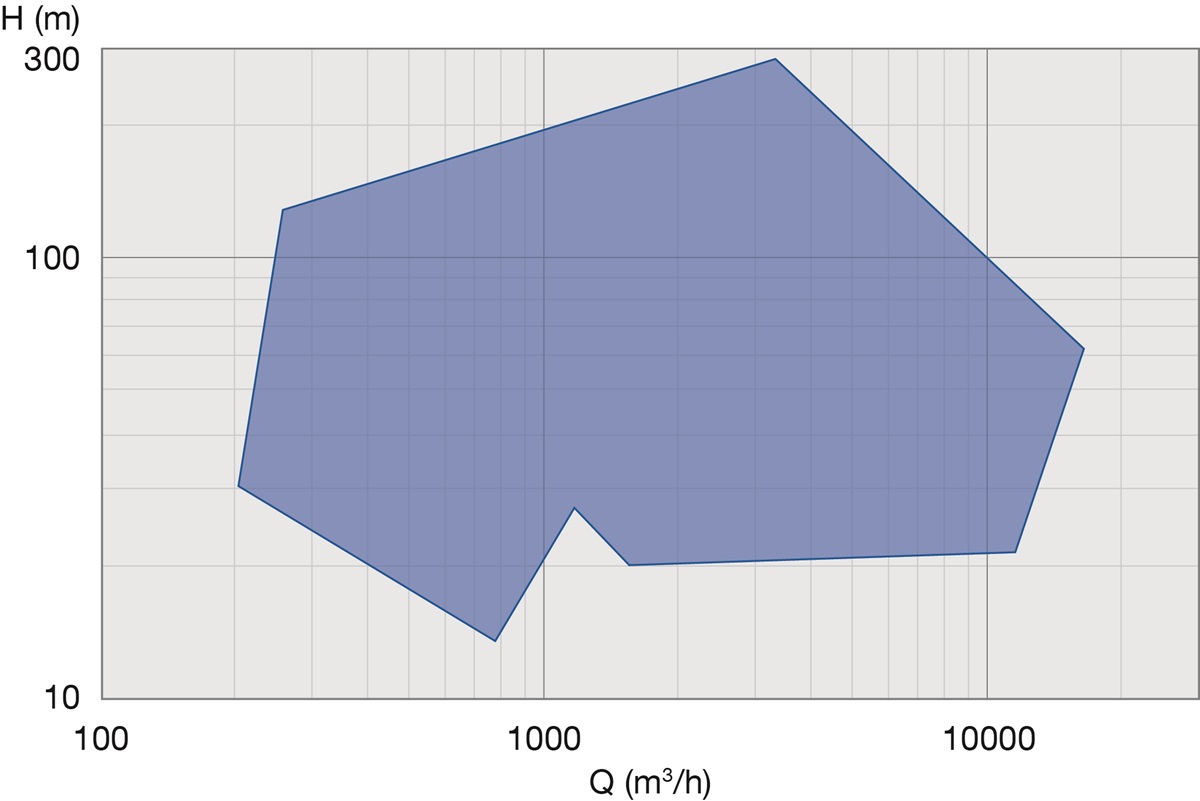

Performance range 50 Hz