- Long-standing and trusted experience in the pulp, paper and board and other industrial segments

- Excellent performance

- Unique and innovative design features minimize life-cycle costs

- Safe operation and easy maintenance and service

KCE™ medium-consistency pumping system

The most advanced technology for semi-medium consistency pumping

KCE™ medium-consistency centrifugal pumps are mostly used in wash press feed applications to pump semi-medium consistency pulp up to 8 % and for high volume flows.

- KCE™ centrifugal pumps are suitable for the most demanding process applications to pump semi-medium consistency fibrous slurries

- up to 8%

- slurries containing solids

- fibrous slurries with high gas content

- All pulp, paper and board semi-consistency fibrous slurry applications and biomass and biofuels applications

Main design features

- Reliable, high-efficiency hydraulics with the innovative Fluider™ technology

- Wide variety of material options for different applications

- Innovative shaft sealing solutions for reliable operation and reduced costs

- Reliable degassing units

- Reliable and heavy-duty bearing unit with a variety of different lubrication options

- Modular design minimize the spare part inventory costs

Key characteristics

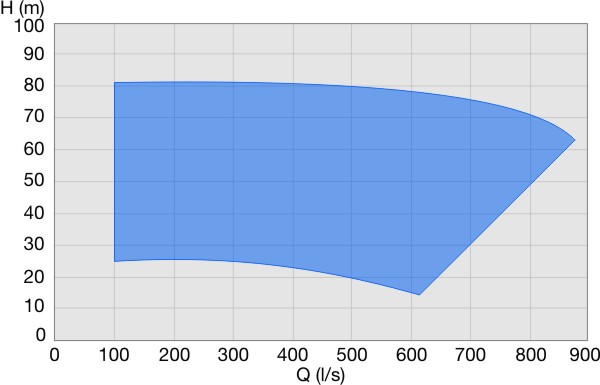

| Capacities | Up to 850 l/s / 13’500 US gpm |

| Heads | Up to 85 m / 280 ft. |

| Pressures | Up to 25 bar / 360 psi |

| Temperatures | Up to 180 °C / 355 °F |

| Discharge sizes | from 150 mm 350 mm / 6-14 in |

| Maximum speed of rotation | Up to 1 500 r/min |

| Performance range | KCE™ medium-consistency centrifugal pumps have wide hydraulic coverage to satisfy the most demanding requirements of semi-medium consistency (intermediate consistency) fibrous slurry applications. |