- Wipes Ready™ cutters prevent materials from forming long strips and reweaving in the waste stream

- Perforated drums prevent the bypass of full wipes or buildup on the grinders while maintaining required flow rates

- Protect pumps and other critical equipment from costly clogs and damage from tough solids

- Allows for easy installation in channels, wet wells and pump stations

- Automatically reverses to clear jams; can be customized for any installation

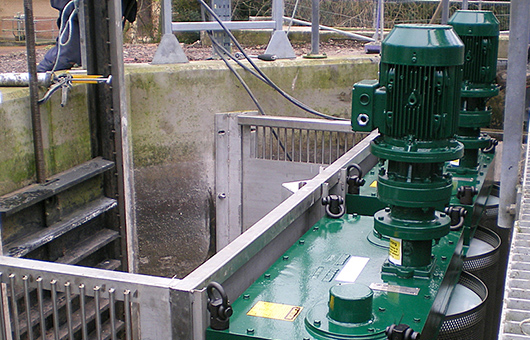

Channel Monster™ open channel grinders

Powerful grinders for pump stations and headworks

- Pump stations where tough solids need to be ground up

- High flows at the plant’s headworks

- Preventing a blocked sewer

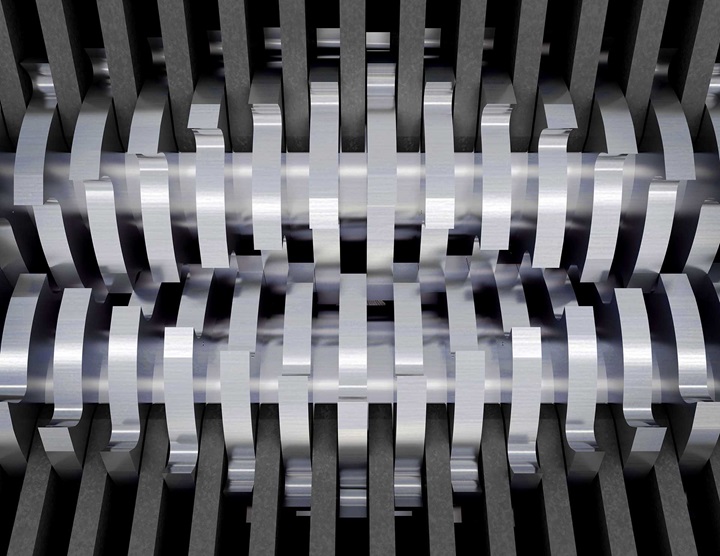

Dual-shafted grinder

- Proven low-speed, high-torque dual shafted grinding which can shred the toughest solids

- Grinds debris smaller than single-shafted machines

- Grinding separates organic from inorganic materials in the waste stream

High-flow screening drums

- High flow screening drums to prevent bypass of unshredded solids without compromising flow

- Standard stainless steel 12 mm perforated drums

Automated monitoring and controls

- Protect pumps and other critical equipment from costly clogs and damage from tough solids

- Auto load sensing reduce interrupts and protects the system from damage

- Adaptive to custom requirements and plant SCADA systems

- Stores operational data

Wipes Ready™ technology

- Wipes Ready technology available which prevents materials from forming long strips and reweaving in the waste stream

Lower operating cost

- Clear pipes and pumps means shorter pump run cycles and lower electrical costs

- Avoid a sewer problem and associated maintenance

- Rotating drum screen: stainless steel

- Cutters and spacers: hardened alloy steel

- Shafts: hardened steel

- End housings, covers and side rails: ductile iron

- Seal faces: tungsten carbide

- Channel frame: stainless steel

The CMD Channel Monster protects pumps and other sensitive equipment by capturing and grinding the toughest wastewater solids in high-flow systems. It utilizes a rotating drum to capture solids and direct them to a powerful, dual-shafted, slow-speed, high-torque grinder designed to shred the tough solids that typically cause sewer problems.

- Hex shafts: 50 mm

- Motor: Standard 4.0 kW; 25:1 reducer

- Cutter size: 120 mm diameter

- Seal max dry working pressure: 10.3 bar

- Perforated drum: 12.7 mm stainless steel

Single drum open channel model

| Single drum models |

Unit height, grinder only mm |

Max flow1 m3/hr |

| CMD1810-XD2.0 | 775 | 421 |

| CMD2410-XD2.0 | 918 | 603 |

| CMD3210-XD2.0 | 1'118 | 873 |

| CMD4010-XD2.0 | 1'318 | 1'152 |

| CMD5010-XD2.0 | 1'572 | 1'525 |

| CMD6010-XD2.0 | 1'835 | 1'922 |

The CDD 2.0 Channel Monster protects pumps and other sensitive equipment by capturing and grinding the toughest wastewater solids in high-flow systems. It utilizes two rotating drums to capture solids and direct them to a powerful, dual-shafted, slow-speed, high-torque grinder designed to shred the tough solids that typically cause sewer problems.

- Hex shafts: 50 mm

- Motor: Standard 4.0 kW; 25:1 reducer

- Cutter size: 120 mm diameter

- Seal max dry working pressure: 10.3 bar

- Perforated drums: 12.7 mm stainless steel

Dual drum open channel model

| Dual drum models |

Unit height, grinder only mm |

Max flow1 m3/hr |

| CDD1810-XD2.0 | 775 | 591 |

| CDD2410-XD2.0 | 918 | 852 |

| CDD3210-XD2.0 | 1'118 | 1'242 |

| CDD4010-XD2.0 | 1'318 | 1'650 |

| CDD5010-XD2.0 | 1'572 | 2'195 |

| CDD6010-XD2.0 | 1'835 | 2'778 |

| CDD2416-XD2.0 | 918 | 1'126 |

| CDD3216-XD2.0 | 1'118 | 1'669 |

| CDD4016-XD2.0 | 1'318 | 2'247 |

| CDD5016-XD2.0 | 1'572 | 3'030 |

| CDD6016-XD2.0 | 1'835 | 3'876 |

| CDD3220-XD2.0 | 1'118 | 2'612 |

| CDD4020-XD2.0 | 1'318 | 3'443 |

| CDD5020-XD2.0 | 1'572 | 4'549 |

| CDD6020-XD2.0 | 1'835 | 5'729 |

The CDD 2.5/3.0 Channel Monster protects pumps and other sensitive equipment by capturing and grinding the toughest wastewater solids in high-flow, heavy solids loading systems. It utilizes two rotating drums to capture solids and direct them to a powerful, dual-shafted, slow-speed, high-torque grinder designed to shred the tough solids that typically cause sewer problems.

- Hex shafts: 64 mm and 76 mm

- Motor: Standard 7.5 kW or 11 kW; 35:1 reducer

- Cutter size: 191 mm and 222 mm diameter

- Seal max dry working pressure: 10.3 bar

- Perforated drums: 12.7 mm stainless steel

Dual drum open channel model

|

Dual drum models |

Unit height, grinder only mm |

Max flow1 m3/hr |

| CDD4010-XD2.5 | 1'449 | 1'650 |

| CDD5010-XD2.5 | 1'695 | 2'195 |

| CDD6010-XD2.5 | 1'965 | 2'778 |

| CDD4016-XD2.5 | 1'449 | 2'247 |

| CDD5016-XD2.5 | 1'695 | 3'030 |

| CDD6016-XD2.5 | 1'965 | 3'876 |

| CDD4020-XD2.5 | 1'449 | 3'443 |

| CDD5020-XD2.5 | 1'695 | 4'549 |

| CDD6020-XD2.5 | 1'965 | 5'729 |

| CDD9020-XD3.0 | 2'875 | 9'305 |

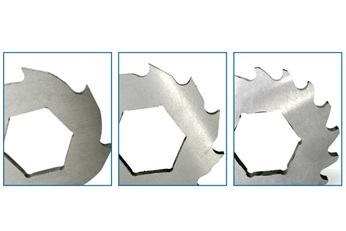

Cutters

- 7,11 and 17* tooth options

* Wipes Ready™ serrated cutters

Motor options

- Single-drive or multidrive system

- IP55 TEFC motor, standard

- IP55 TEFC motor for ATEX: (Ex d IIC T4), optional

- IP68 immersible motor ATEX: (Ex de IIB T4), optional

Smart controller

- Load-sensing control system automatically reverses to clear jams

- Powder-coated mild steel or stainless steel IP65 enclosures

Custom wet well frames

- Stainless steel guide rails make Channel Monster installation and retrieval simple and quick, even in deep or narrow pump stations

- Frames include choice of stainless steel

Overflow bar screens

Stainless steel bars are attached to frame or sub-channel and provide additional overflow capacity

|

CMD-XD 2.0 single drum Channel Monster |

CDD-XD 2.0 double drum |

|

| 17 tooth Wipes Ready cutters | Optional | Optional |

| Delta P side rails | Yes | |

| Optimized cut control | Yes | Yes |

| 12.7 mm perforated drums | Yes | Yes |

Wipes Ready technology

Channel Monster sewage grinders are available with the unique Wipes Ready technology. It is designed to capture all wipes in the waste stream and shred them into small pieces that will not reweave to form ropes and ragballs that cause problems in sewage systems.

The Wipes Ready technologies applied in Channel Monster sewage grinders are:

- Wipes Ready cutters – A combination of serrated cutters and knurled spacers cuts wipes in two directions. The result is smaller particles that cannot reweave downstream.

- Delta P Side Rails – Direct solids into the cutters without sacrificing flow rate and prevent debris build-up in the grinder

- Optimized cut control (OCC) – The OCC gear ratio optimizes shaft speeds to enhance the cutting action and cleaning of the cutters, which in turn improves the performance and life of the grinder.