- High efficiency in high flow and low head applications

- High durability due to its heavy duty construction

- Maximum reliability also in high-corrosion applications

- Low maintenance costs

- High adaptability due to flexible design

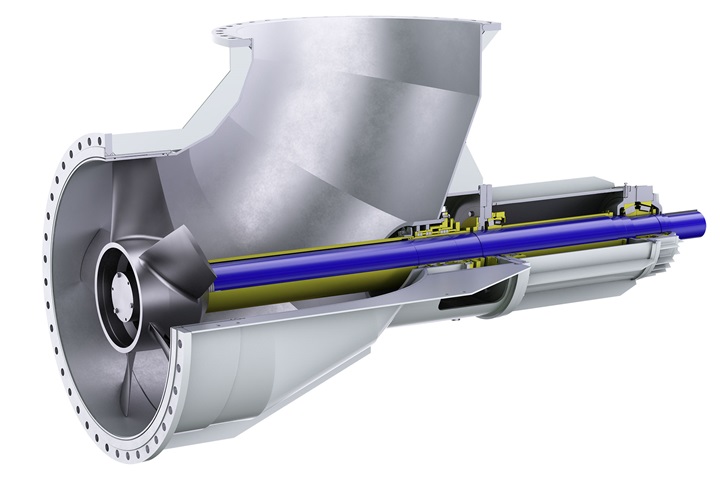

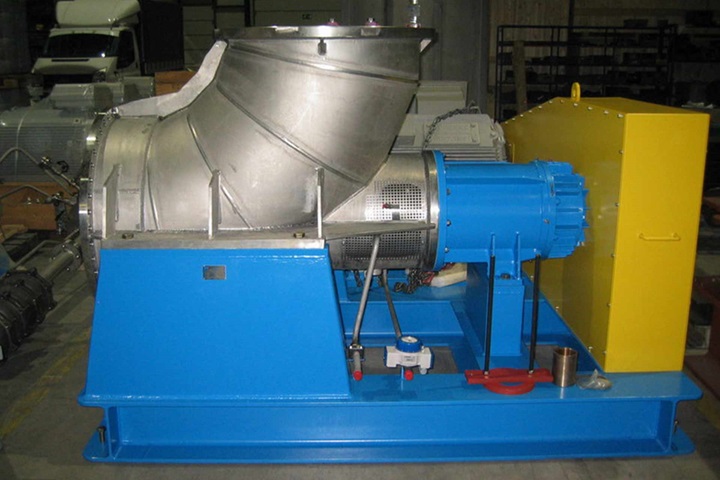

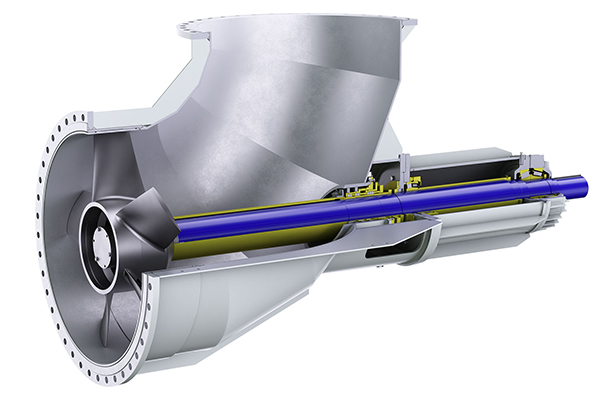

CAHR axial flow pump

Heavy duty design for severe conditions

The CAHR pump range has been designed for high flow and low head pumping applications. With its heavy-duty construction and flexible design, it is suitable for all kinds of industrial schemes and various types of liquids for both highly corrosive and slurry applications.

- Corrosive and abrasive liquids

- Solid-contaminated liquids

- Chemicals

- Evaporation

- Crystallization

- Mining/minerals

Main design features

- Innovative hydraulics increase efficiency and flow while reducing NPSHr

- Flexible design offers high suitability in various industrial applications

- Cast or fabricated design available in wide range of materials

- Vertical design for cooler circulation and phosphoric acid slurry circulation

- Higher flows upon request

Key characteristics

| Capacities | up to 40'000 m3/h / 176'000 USgpm |

| Heads | up to 8 m / 26 ft. |

| Pressures | up to 10 bar / 145 psi |

| Temperatures | from -40°C to 180°C / -202°F to 356°F |

Case Studies

-

Long-term successful collaboration with major fertilizer producerOne of the world’s top fertilizer producers operates a big fertilizer complex in South America. A few years ago, the company started an expansion project that includes three additional phosphoric acid concentration lines. Sulzer was selected to supply the critical evaporator circulation pumps.

-

Optimizing the performance of axial flow pumps in evaporator circuitsAxial flow pumps are widely used in evaporator circuits in chemical and some petrochemical processes. Frequently overlooked, the proper design, operation and maintenance of these pumps can have a crucial effect on process performance, energy efficiency and equipment reliability. Read the whole article.

-

Pumping equipment in phosphate fertilizer processesPumps are at the heart of phosphate fertilizer production, and correct equipment selection that takes into consideration hydraulic design, materials of construction, application knowledge, duty point and maintenance regime are critical to achieving reliable long-term pumping operation and maximum plant production. Read the whole article.

-

Driving up efficiencyThe adoption of electric vehicles across the world is increasing rapidly and this demand needs to be matched by the supply of batteries. As new processing plants and manufacturing facilities are constructed, it is important that they employ the latest in pumping technology to ensure optimum reliability and efficiency. Read the article.

-

An almost everlasting evaporator circulation pumpEl-Nasr Company for Intermediate Chemicals (NCIC) is the biggest fertilizer company in Egypt and a leading company in the North African market. Its Al-Fayoum fertilizer complex was started in 2011 and it includes a phosphoric acid plant (150 tons per day P₂O₅). Sulzer was the selected vendor for the supply of the axial flow pumps, among many other pumps.

-

Case studiesWherever fluids are pumped, mixed, controlled or applied, we are there. See how our solutions create value for customers and learn how we can make your pumping and mixing processes more efficient and profitable, safeguarding your production and ensuring lasting reliability.

Documents

Related links

Product and services

-

Agitators, dynamic mixersSulzer SALOMIX™ and Scaba mixing and agitation technology offers a wide range of products for industrial applications. Side-mounted horizontal and top-mounted vertical agitators, dynamic chemical mixers, and tower and tank flow management products guarantee effective mixing and agitating processes.

-

Pump servicesReliable and efficient pump operation is critical for your business. Therefore you need a service partner that can respond fast and flexibly. Our pump services are second to none and provide solutions that help you to improve your processes and business performance.

-

Original pump spare partsOriginal spare parts machined to the correct tolerances and clearances give a perfect fit first time, every time. Our commitment to continuous improvement often allows us to supply parts with improved features, thus enhancing performance, extending equipment life, while reducing maintenance costs.

-

Service kitsWhen your equipment needs to be repaired you shouldn’t have to worry about spending valuable time searching for the right parts – or even worse, finding out that some small but vital parts are missing. With Sulzer service kits you get everything you need in one package.

-

Sulzer mechanical sealsSulzer mechanical seals are strong by design and have been proven very reliable in various pumping applications.

Industries

-

Food and beverageFood and beverage production relies on our pumping and mixing solutions. Special pumps and agitators have been developed for sugar, starch, and sweetener production. Separation equipment is often used in beverage manufacturing and our process technologies support purification and concentration.

-

Mining and metalsLong experience and detailed knowledge of metals and mining applications with different raw materials makes Sulzer a reliable pump supplier for these industries.

-

Pulp, paper and boardSulzer is the world leader in innovative, reliable, and proven pumping, agitation and mixing solutions for the pulp and paper industry. Our deep process and application knowledge is based on long-term close co-operation with the producers, machinery suppliers and engineering companies.

-

Municipal clean waterWe provide reliable pumping solutions for various industrial water and wastewater treatment processes. Our technologies enable the removal of organics.

-

Municipal wastewaterSulzer plays a major role in returning clean water to its source, by providing effective solutions for wastewater collection and treatment focused on safety, reliability, and efficiency. Sulzer offers the most up-to-date range of pumps, submersible mixers and agitators, aeration systems, high speed compressors and equipment controllers, supported by a world wide service organization.

-

Oil gas and chemicalsHigh-performance pumps from Sulzer provide cutting edge solutions for the production, processing and transportation of hydrocarbons and CO2. Our technologies enable efficient separation processes for liquids and gas. We provide reliable services for compressors, turbines, motors, and generators through our global aftermarket network.

Videos

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

Careful commissioning of the pump plays a key role in the safe and reliable use of the pump

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

Connecting the pipes to the pump correctly is essential for ensuring the reliability of the pump

Talk or write to our experts to find your best solution.