- Long and trusted experience in all industrial segments

- Excellent performance

- Exceeds standard requirements of international ISO 5199 standard

- Suitable for the most demanding industrial applications

- Unique, patented and superior design features minimize life-cycle costs

- Quick and easy installation, safe operation, easy maintenance and service

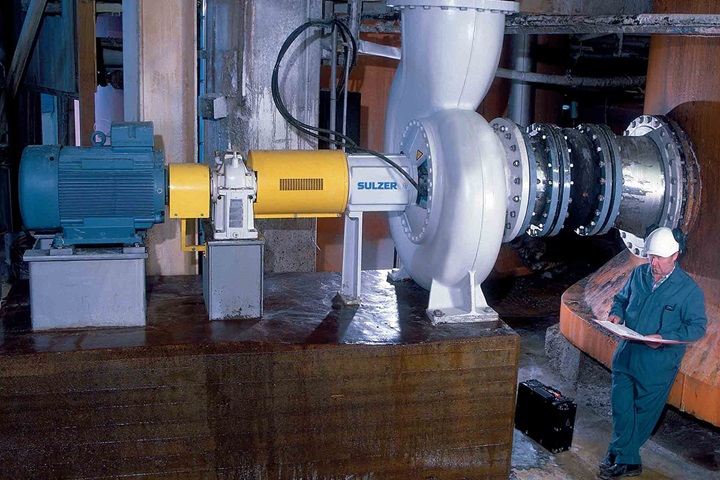

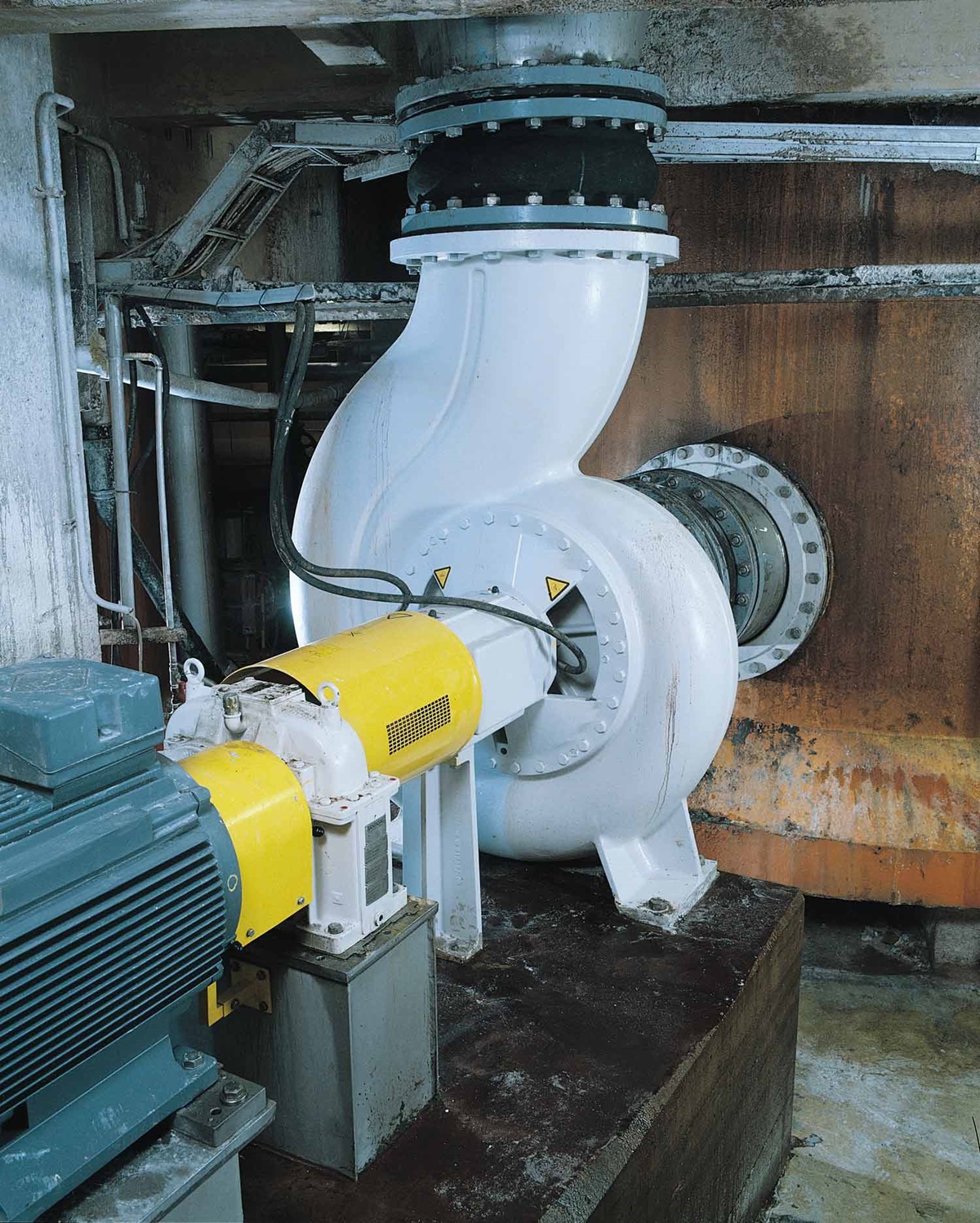

AHLSTAR WPP/T wear-resistant process pump range

Tough against wear, gentle against process

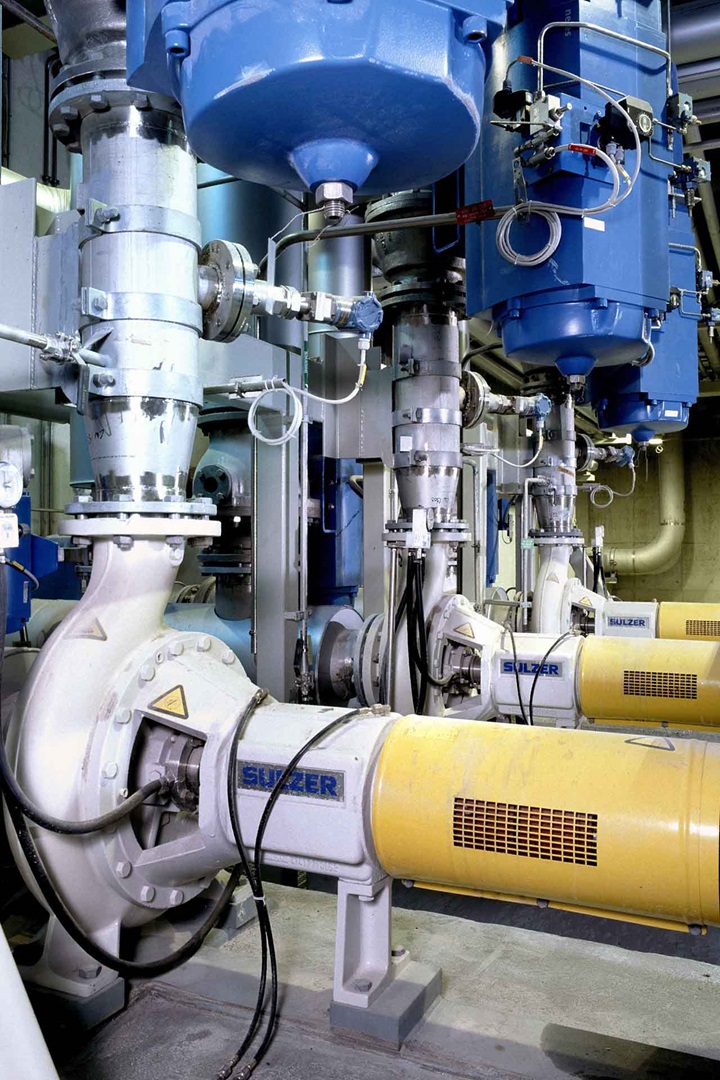

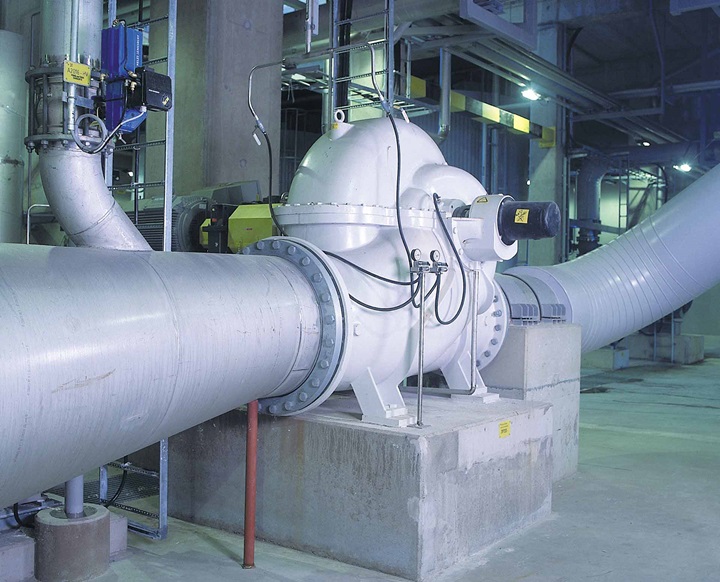

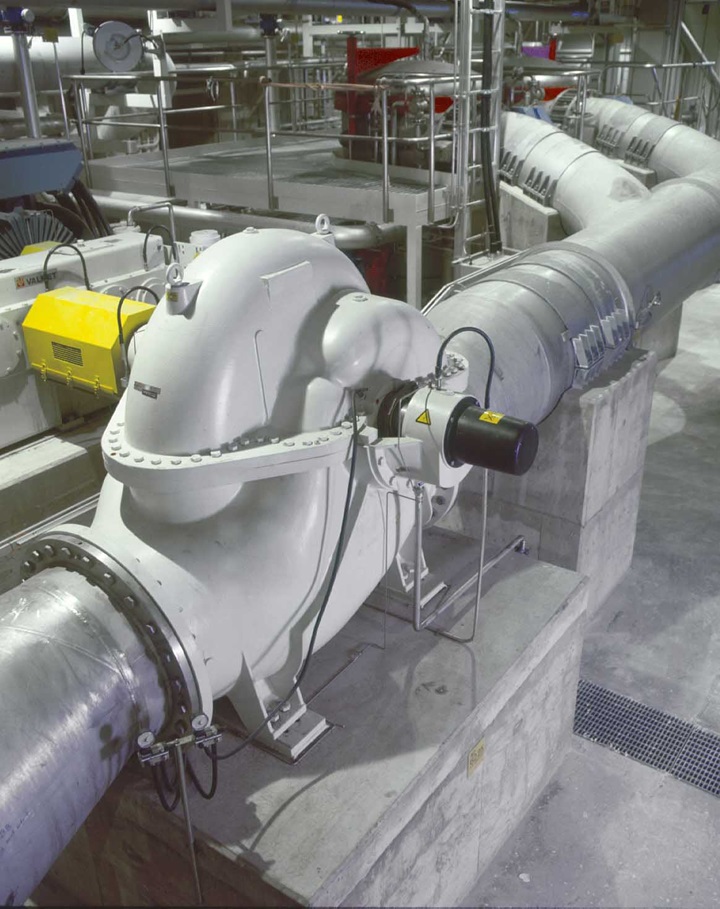

AHLSTAR WPP/T wear-resistant end-suction single-stage centrifugal pumps are designed for abrasive and erosive pumping applications, such as lime milk and mud, and coating pigments.

- Abrasive and viscous liquids

- Abrasive fibrous slurries

- Abrasive non-fibrous slurries

- Abrasive large solids and gas containing liquids and slurries

- Gas containing slurries in self-priming applications

Main design features

- Versatile, reliable, high-efficiency hydraulics and material options

- Innovative shaft sealing solutions for reliable operation and reduced costs

- Innovative and reliable degassing and self-priming units

- Reliable, simplified and heavy-duty bearing unit with a variety of different lubrication options

- Modular design minimize the spare part inventory costs

Key characteristics

| Capacities | up to 7,000 m3/h / 31,000 US gpm |

| Heads | up to 110 m / 360 ft. |

| Pressures | up to 16 / 230 psi / 360 psi, depending on material and size |

| Temperatures | up to 180 °C / 355 °F |

| Discharge sizes | from 32 mm / 1 ¼ in to 600 mm / 24 in |

| Maximum speed of rotation | up to 3,600 rpm |

Documents

Brochures

-

Sulzer ejector for primingpdfLanguages:

Case studies

Case studies and articles

-

Energy-efficient and durable slurry filter feed pump for a phosphoric acid plantBy combining optimal hydraulics and wear-resistant materials of construction in a pump replacement, Sulzer helped a leading phosphate fertilizer producer to increase productivity. Sulzer’s AHLSTAR WPP endsuction single-stage pump has proven to be the right choice. It meets the performance requirements while using less energy and drastically cutting maintenance frequency.

-

AHLSTAR pump range ─ the reliable beast of burden for the process industryAHLSTAR end-suction single-stage centrifugal pumps are designed to work with all types of liquids also in demanding industrial applications such as the pulp, paper and board, biofuels, mining, metals, and fertilizers industries. AHLSTAR pumps stand for reliability, peak performance, high efficiency, and low operating costs. Read the whole article.

-

Raízen selects Sulzer for next generation biofuel productionBrazil’s largest producer of ethanol from sugarcane waste is embarking on a major wave of investment. With plans to build 20 second-generation processing facilities over the next seven years, Raízen has picked Sulzer as a key technology supplier. Read the whole article.

-

Sulzer to supply pumps and mixers to the new bioproduct mill in Kemi, FinlandMarch 24, 2021Metsä Fibre, part of the Finnish forest industry company Metsä Group, and Sulzer Pumps Finland have signed an agreement for the supply of process pumps, medium-consistency pumps and mixers for the main processes of the bioproduct mill that will be built in Kemi. The delivery will include several hundred devices.

-

AHLSTAR and SNS pumps throughout corn ethanol processFS - Fueling Sustainability, located near Lucas do Rio Verde, Mato Grosso, is the first corn-only ethanol plant in Brazil. The production started in 2017 with an initial capacity of 250 million liters per year. The facility utilizes the latest process technologies from ICM, an innovative company headquartered in Colwich, KS, USA that has become a world leader in biorefining technologies and processes. In addition to bioethanol, some high-value coproducts such as corn oil as well as high-protein and high-fiber dried distiller’s grains are produced. The plant also generates electricity from the biomass, partly for internal use and the surplus for sale.

-

AHLSTAR pumps with maintenance-free dynamic sealsThe paper mill includes a conventional wastewater treatment plant which treats about 20'000 m³ per day of process effluents. At the output of the plant, about 30% of the discharge water is reintroduced into the mill circuit and the remaining 70% is returned to the Moselle river. Despite the increasing stringency on the quality of the discharge water, no environmental incident has occurred since the start-up of the plant.

-

Wear resistant process pump for metals and fertilizers applicationsIn the minerals and metals processing industry or in fertilizers production, ideal application conditions where a pump is operating at its best efficiency point (BEP) and the system is stable very seldom occur. Wear and corrosion are bound to a shortened lifetime of the pump in demanding applications. Read the whole article.

-

Trusted partner for new wood-based processesSulzer is a company with long and solid experience and proven expertise in several important customer segments. Pulp, board and paper processes and applications as well as new ones based on wood raw materials represent high-priority commitment and partnership areas for the business and product development organization. Read the whole article.

-

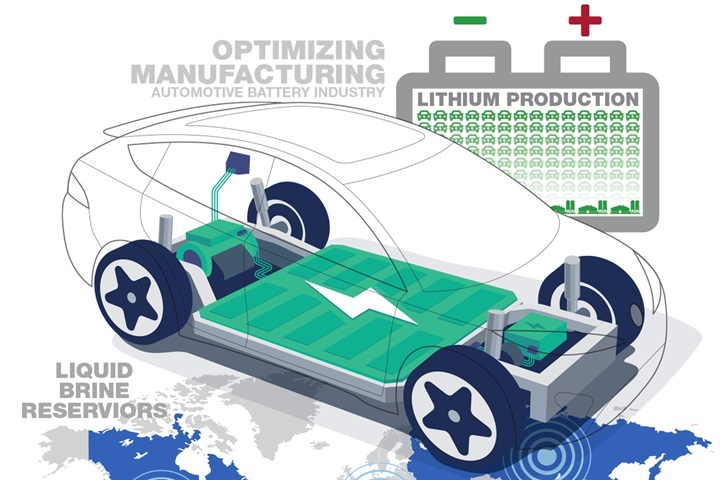

Driving up efficiencyThe adoption of electric vehicles across the world is increasing rapidly and this demand needs to be matched by the supply of batteries. As new processing plants and manufacturing facilities are constructed, it is important that they employ the latest in pumping technology to ensure optimum reliability and efficiency. Read the article.

-

Pump solutions for mine water managementMines require water. At the same time, because many mine working areas are below the water table, the removal of water is a major challenge. Water is critical for every mine site – without water the mine could not operate. Pumps are, therefore, one of the most used machines in mines today. In this article we will review the concepts of mine water and mine water management as well as the most common pumping applications. Read the whole article.

-

Expert solutions for mining and quarryingThe mining, quarrying and construction industries present some of the most challenging applications encountered by pumps. The range of process fluids handled varies quite significantly across these processes, ranging from clear water to heavy slurries and from alkaline, pH neutral to highly corrosive fluids. As well as having to deal with the process requirements, products must also be compliant with the environmental and legislative constraints in play across geographies. Read the whole article.

-

Energy efficiency of pumping systemsPumping systems account for more than 20% of the world’s electrical energy demand, and in certain industrial plant operations they can be responsible for between 25% and 90% of the energy usage. Improving the energy efficiency of the pumping system will reduce production costs and support green credentials. Read the whole article.

-

Pumps in the circular economySulzer has a long history of supporting renewable power generation, plastic recycling and sustainable practices as a whole in all its operations in manufacturing and spare parts as well as services centers. Read the whole article

-

Supporting sustainable fuel productionSulzer is at the forefront of engineering excellence and quality, delivering best-in-class solutions to support companies in important growth industries, such as biobased, renewable energy production. Understanding precisely what customers need, as well as maintaining the highest standards in manufacturing and service has led to many significant project wins, not least the collaboration with Inpasa, Latin America’s largest producer of corn ethanol. By the end of 2024, this partnership is anticipated to have grown to the delivery of almost 2’000 pieces of equipment, including pumps, sealing systems, agitators and static mixers across six production plants in Brazil.

-

Case studiesWherever fluids are pumped, mixed, controlled or applied, we are there. See how our solutions create value for customers and learn how we can make your pumping and mixing processes more efficient and profitable, safeguarding your production and ensuring lasting reliability.

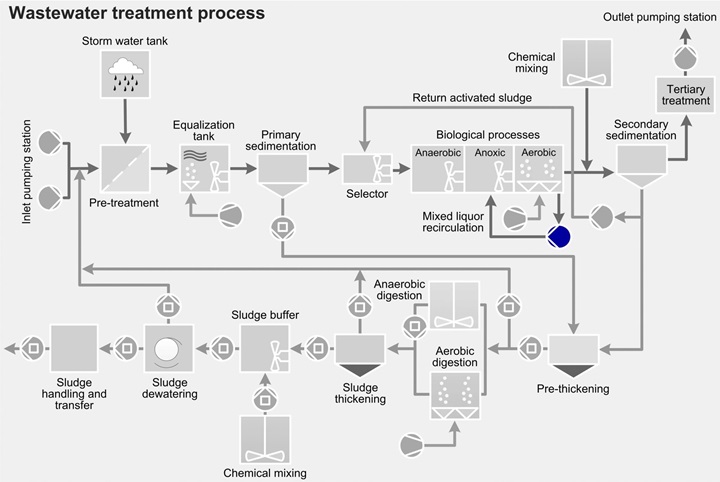

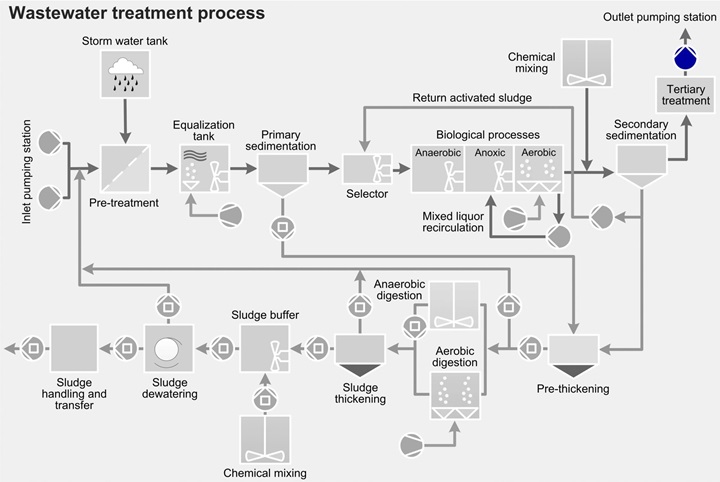

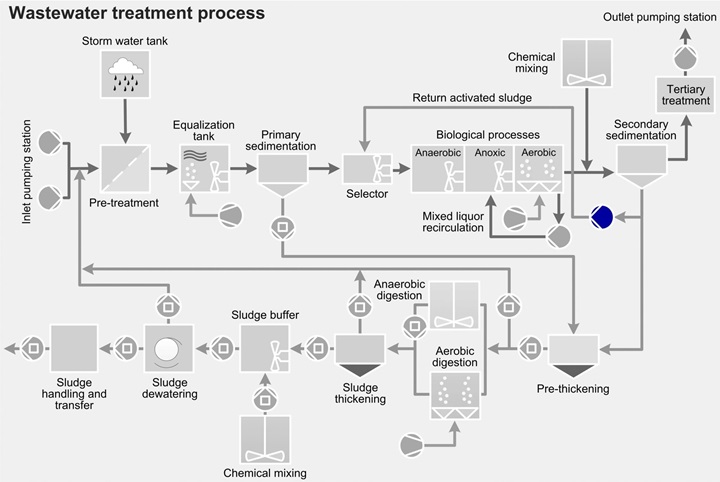

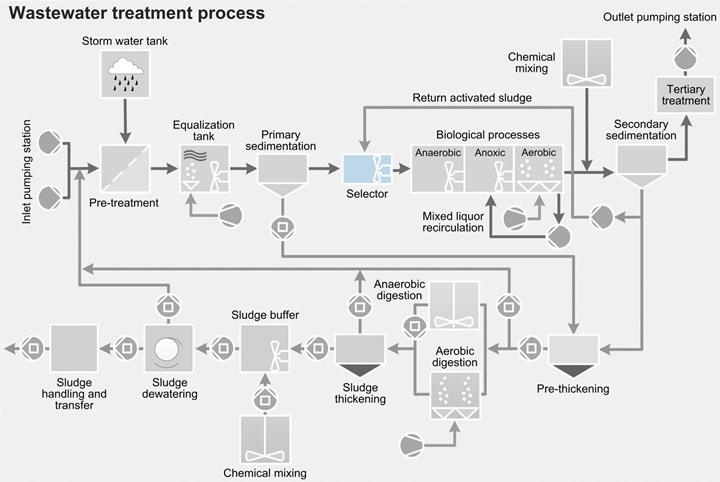

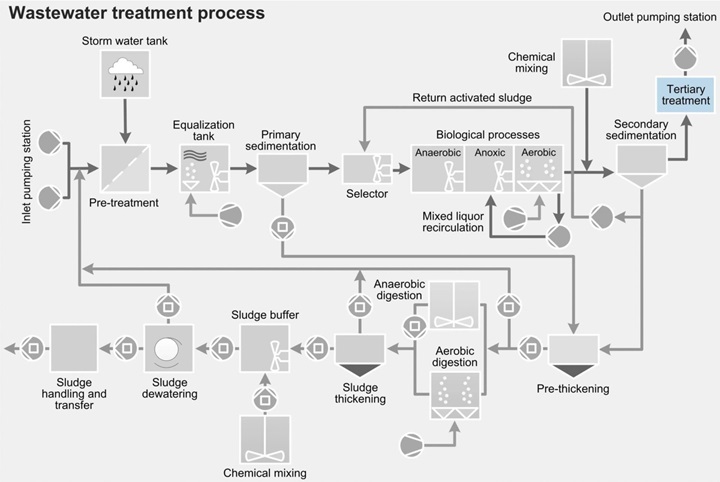

Applications

-

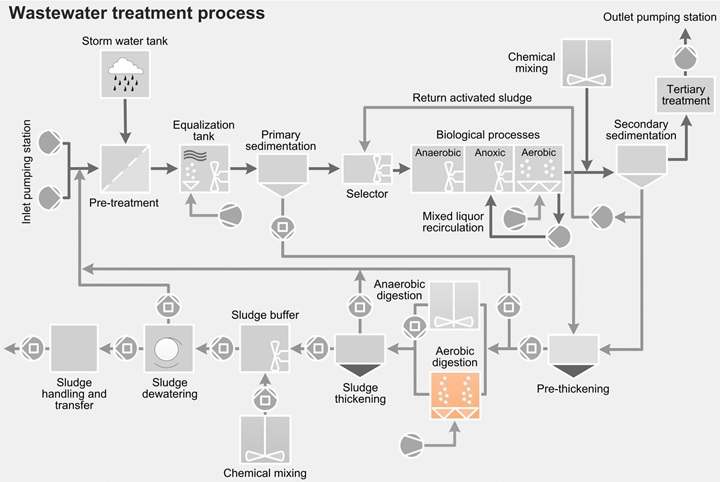

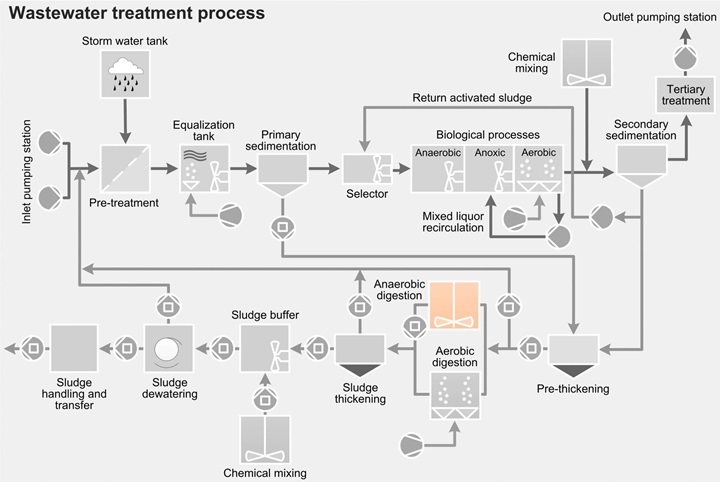

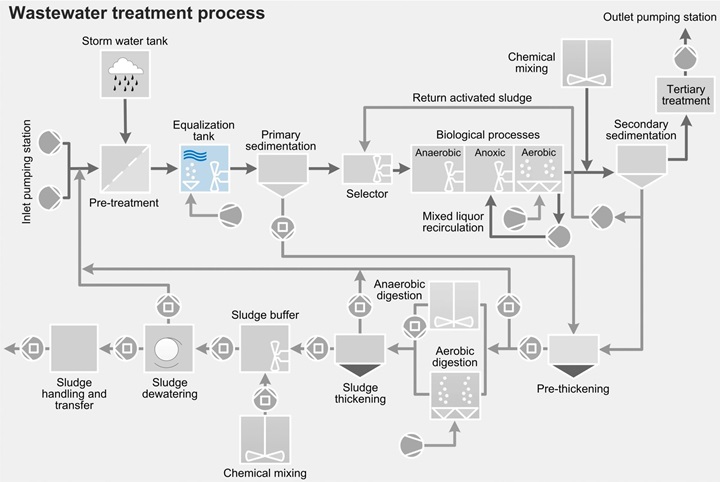

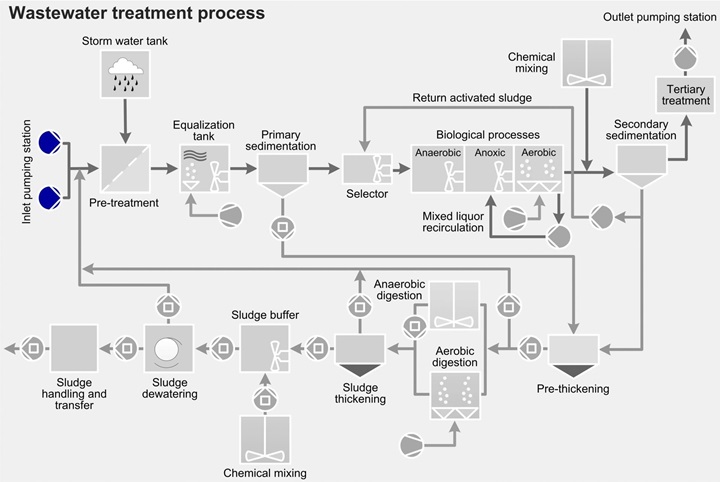

Aerobic digestionIn aerobic digestion in wastewater treatment, microorganisms continue to break down the organic material. These microorganisms need aeration in order to function, and some level of mixing is required to keep the process efficient and reliable. The result is reduced sludge volume and the prevention of odor. Sulzer has highly suitable products such as compressors, aerators and disc diffuser systems to support the process in the aerobic digester tank.

-

Anaerobic digestionAnaerobic digestion requires temperature equalization and proper homogenization of the biomass to achieve a high gas production and to avoid sedimentation of organic matters. The surface crusts must be broken and prevention of foam must be managed if there are foaming tendencies. Sulzer can provide efficient and reliable Scaba agitators for digesters with high-efficiency propellers. Muffin Monster™ grinders upstream from the anaerobic digesters condition the sludge before digestion, improving the homogenization of the biomass and protecting the equipment downstream.

-

Bio-based applicationsBio-based chemicals, fuels and plastics are future building blocks to sustainability. For more than 40 years, we have been working hands-in-hands with technology providers and end-users to develop and improve efficiency and purity of processes devoted to the production of bio-based intermediates, products and fuels.

-

Bio-based process developmentFind and develop efficient process equipment for bio-based products in an agile way with Sulzer as your trusted partner.

-

BiodieselSulzer has develop a unique know-how based on its distillation technology to improve both clarity and purity of biodiesel. Single cut methyl esters can be used as solvents, intermediates for fatty alcohol and raw material for mono-ethanolamides.

-

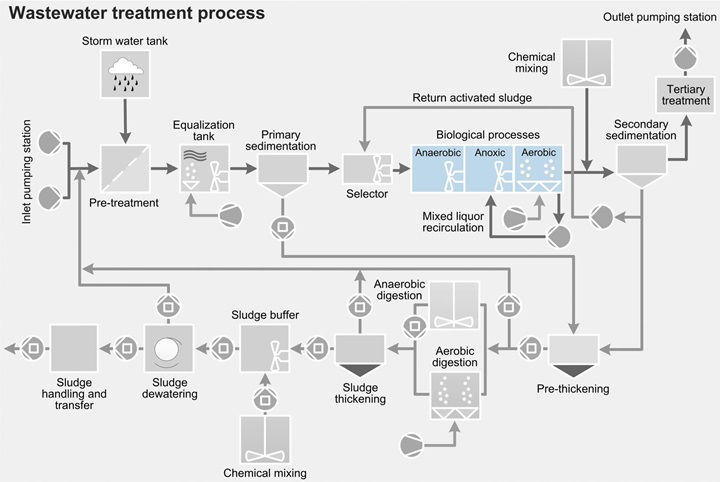

Biological processThe target of the biological process in wastewater treatment is to remove organic, biodegradable substances via the metabolism of microorganisms and related biochemical processes.

-

Cellulose-based bioproductsExplore different ways cellulose-based bioproducts can be industrially processed. Sulzer employs and develops multiple application technologies for various feedstocks.

-

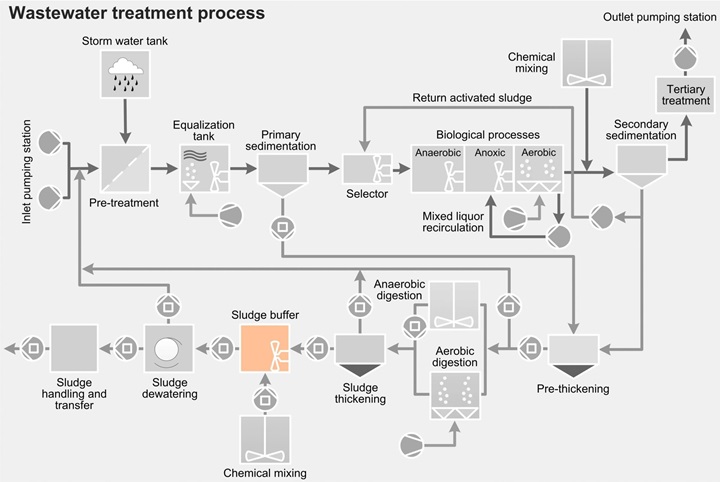

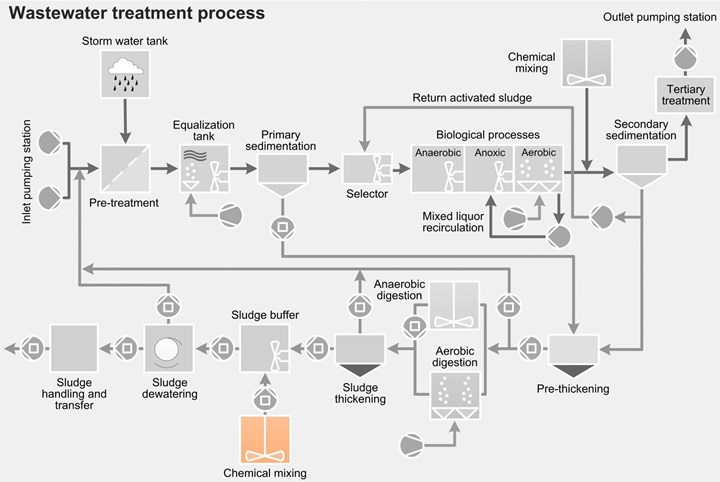

Chemical mixing - sludgeSometimes it is necessary to mix chemicals into the activated sludge before it enters the secondary sedimentation tank. For example, chemicals may be used to perform phosphorous removal on the effluent from the biological process. Many plants use chemicals to improve sludge thickening just prior to the sludge buffer tank.

-

Chemical mixing sewageChemicals must sometimes be mixed into the activated sludge before it enters the secondary sedimentation tank. Whenever this done, it is important to achieve an even distribution of the chemicals. Chemicals may be added to perform the chemical removal of phosphorous on effluent from the biological process. In other circumstances, chemicals such as cationic polyelectrolytes with a high molecular weight may be added to improve the quality and settling ability of flocs formed in the activated sludge process.

-

Chemical pulp fiber lineProven pumping, mixing and agitation solutions for your cooking, washing, screening, oxygen delignification, bleaching, and storage processes to ensure process reliability, high efficiency, and low operating costs.

-

Chemical recoverySulzer’s extensive product portfolio is designed to meet the most demanding hydraulic coverage requirements in your evaporation, recovery boiler, and white liquor preparation processes.

-

Chemical recyclingSuRe™ Technologies, is an integrated group of solutions that provide a sustainable path to transform end-of-life mixed plastic waste into high-value hydrocarbons

-

Chemicals for Pulp Paper and BoardTailored designs, features and material selections to meet the most demanding pumping, mixing, and agitation challenges in the production and preparation of chemicals, tall oil production, and lignin processing.

-

Coating and finishingA wide selection of highly efficient and reliable pumps and agitators for your pigment handling and color coating processes.

-

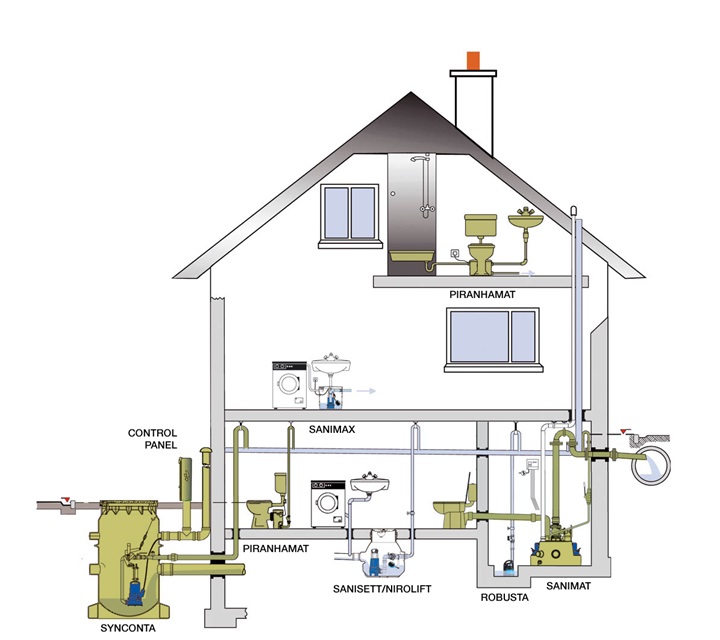

Commercial waste disposal from toiletsCommercial wastewater from toilets comprises all sewage water flushed from toilets on commercial, industrial or public properties.

-

Commercial wastewater without toilet wasteCommercial wastewater without toilet waste includes drainage and grey wastewater.

-

Copper applicationsMaximize efficiency and durability in copper applications, while reducing energy costs and water consumption. With an advanced selection of materials for a comprehensive portfolio, Sulzer ensures reliable performance at minimized downtime, even in demanding environments.

-

Domestic waste disposal from toiletsDomestic wastewater from toilets comprises all sewage water flushed from toilets or residential properties.

-

Domestic wastewater without toilet wasteDomestic wastewater without toilet waste includes drainage and gray wastewater.

-

Downstream oleochemicalsThe majority of the downstream oleochemicals are concentrated or purified using thermal separation processes such as distillation. As an expert in thermal separation processes, Sulzer has developed unique hybrid processes using combinations of its most advanced separation know-how.

-

EqualizationThe task of mixing in the equalization process is to blend the wastewater in order to prevent sedimentation, stratification and odor formation. It may also be necessary to mix and homogenize wastewater streams that arrive from different sources. Because the water level in the equalization tanks varies significantly and can sometimes be very low, high demands are placed upon the mixers.

-

Fatty acidsSulzer fractional distillation is a well-established and recognized technology in the oleochemical industry to purify fatty acids mixtures to the right of fatty acid ratio(s) or to produce single cut fatty acid at the desired purity

-

Foam formingWe provide advanced equipment for executing and developing sustainable foam forming applications for wood, pulp, textiles, and bio-based products.

-

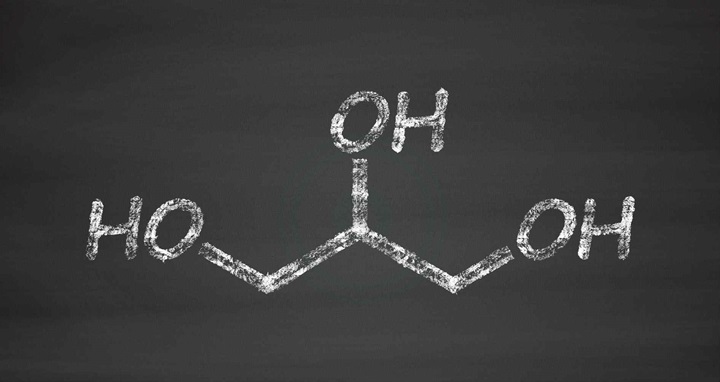

GlycerinGlycerin is a valuable by-product from the fatty acid and biodiesel value chains. Sulzer has developed a technology based on its proprietary distillation technology to refine glycerin to pharmaceutical grade glycerin and up to ultra high pure glycerin grades.

-

Industrial water and effluent treatmentSulzer has a deep knowledge in wastewater treatment, and with our wide product portfolio we can now offer energy-efficient and reliable solutions for your water collection, neutralization, flocculation, sedimentation, cooling, aeration, sludge storage, digestion, and dewatering processes.

-

Inlet pumping stationInlet pumping stations are somewhat similar to large terminal pumping stations. Depending on the depth of the incoming sewer, the lifting heads can range from around 2 up to 30 meters. To prevent hydraulic shock loads, which negatively impact the biological process, the stations often make use of variable-speed drives and/or several pumps in parallel.

-

Lithium applicationsWith a comprehensive global reference base, broad range of reliable pumps and other process equipment and full line of lifecycle services Sulzer is the chosen equipment supplier for lithium processing. Our equipment is constantly developed for more efficient extraction and production of lithium-based compounds like lithium carbonate, lithium hydroxide, and lithium chloride.

-

Mechanical pulp lineSulzer’s ideal product portfolio for challenging pumping, agitation, and mixing operations in refining, grinding, CTMP, screening, reject handling, and bleaching processes.

-

Microfibrillated celluloseWe are actively involved in developing process equipment for microfibrillated cellulose. Our broad portfolio of industrial pumps, agitators, and mixers suit the specific needs of MFC.

-

Mine water managementSulzer offers a comprehensive portfolio of pumps and process equipment for abrasive and corrosive environments in mine water management applications.

-

MiningWhether on the surface or underground, the conditions in mines are harsh. Besides the mud, slurry, stones, and rocks, there are large volumes of water to remove in order to keep production moving. Our dewatering pumps are rugged and ready, taking on the toughest drainage and sludge removal.

-

Mixed liquor recirculationWhen denitrification is followed by a physically separated nitrification step, the nitrates formed during nitrification must be recirculated. The nitrates are pumped back into the denitrification step, where the anoxic process splits the nitrate molecules into nitrogen and oxygen. This frees the nitrogen into the air. This application is best served by submersible recirculation pump types ABS XRCP and RCP, the submersible mixed flow column pump type ABS AFLX and the submersible propeller pump type ABS VUPX.

-

Outlet pumping stationsOutlet pumping stations are required when the level of the treatment plant is lower than that of the receiving water. This is especially true when discharging into a river, which can rise during heavy rain or flood periods, or into the sea, where the level varies with the tide. Outlet pumping stations may also be needed to compensate for increasing frictional losses in the outgoing pipe at high flows, for example in long sea outfall pipes.

-

Paper and board machine and systemsSulzer’s extensive product portfolio is designed to meet the most demanding hydraulic coverage requirements and for all types of liquids, making it ideal for challenging pumping, agitation, and mixing operations in stock preparation, PM approach system, broke system, white water system, vacuum system, condensate system, and shower water system processes.

-

Power plantsSulzer’s extensive product portfolio to maximize the performance and reliability of your solid organic fuel biomass power plant, solid industrial or municipal waste fuel biomass power plant, and liquid or gaseous organic fuel biomass power plant processes.

-

Pulp drying machineIncreased hydraulic excellence for your approach, cleaning, drying machine, vacuum, broke, and white water system processes.

-

Recycled fiber lineEnergy-efficient products with low life cycle costs and a lighter environmental footprint for your pulping, screening & cleaning, flotation, washing, and bleaching processes.

-

Return of activated sludgeOutlet pumping stations are required when the level of the treatment plant is lower than that of the receiving water. This is especially true when discharging into a river, which can rise during heavy rain or flood periods, or into the sea, where the level varies with the tide.

-

SelectorThe purpose of the selector tank is to control and limit the growth of filamentous bacteria, and then to enhance the sedimentation ability of the sludge. Sulzer provides a number of solutions for creating optimal conditions in the selector.

-

Separation applicationsWe are a forerunner in the development of mechanical separation applications for bio-based raw materials. Our solutions produce ingredients in a very pure form, suitable for further processing.

-

Sludge buffer tankThe sludge buffer tank can be used for a variety of purposes. The most common application is the blending and homogenization of highly concentrated primary, secondary or digested sludge. The solution used to mix the sludge itself, or to mix the sludge with the dosed thickening chemicals, depends on the design and volume of the sludge buffer tank. Submersible mixer types ABS XRW and RW, as well as the agitator type Scaba, can be used to provide highly efficient mixing. Positive displacement, progressing cavity transfer pumps and Muffin Monster™ grinders are used for solids reduction and sludge transfer from sludge feed to sludge dewatering process.

-

Sludge handling and transferSulzer pumps, mixers, grinders and agitators are used to condition, transfer, blend and handle sludge. Our progressing cavity, positive displacement pump range, provide a near constant flow rate with suction lift capability, for handling all types of non-Newtonian sludge and cake processes, typically demanded within the wastewater treatment plant. Maintain in place features ensure any process downtime due to the change out of wear components is kept to a minimum. The Muffin Monster™ grinders protect the equipment downstream. The sludge conditioned by grinders will not clog valves, heat exchangers, digesters, centrifuges and other equipment on the sludge line.

-

Specialty estersSulzer has developed a unique process based on reactive distillation technology that combines both process steps into one, enabling, for the first time, continuous productions of isopropyl-esters.

-

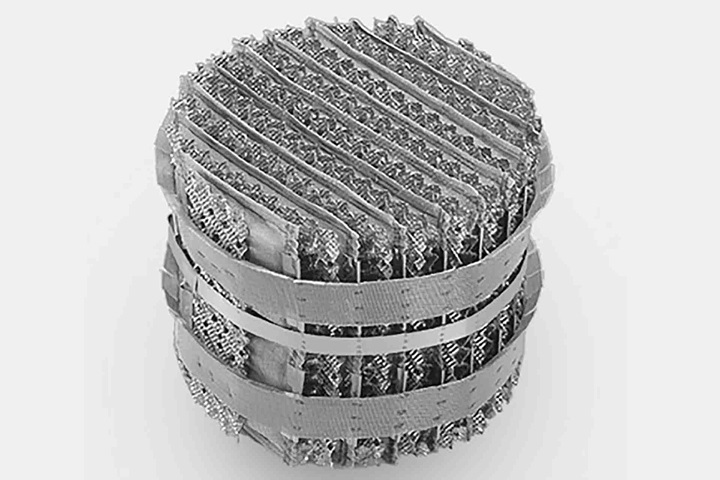

Tertiary treatmentTreated wastewater may occasionally require further treatment. Local discharge rules may pose strict limits that cannot be fulfilled by even the most effective process, or a higher quality of effluent may be requested for its reuse. When tertiary treatment is needed, various levels of filtration can be applied, including very fine filtration. Often, however, a final step of mixing and aeration is sufficient to achieve the target. When this is the case, Sulzer's submersible mixer types ABS XRW and RW can be used, along with submersible aerator type ABS TA–TAK and disc diffuser system types ABS PIK, DS and Sucoflow.

-

Test equipment rentalRental equipment for textile and bio-based process development initiatives either at customer facilities or Sulzer’s development center.

-

Water supplyMeeting today’s challenges and high requirements within water intake, sedimentation, sludge treatment, fine screening, and water distribution processes.

-

Wood yardEnergy-efficient products with low life cycle costs and a lighter environmental footprint for your debarking, washing, chipping, screening, and bark and waste streams handling processes.

Related links

Products and services

-

AHLSTAR A process pump rangeAHLSTAR A end-suction single-stage centrifugal process pumps are used for demanding industrial applications to ensure process reliability, high efficiency and low operating costs. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR APT process pump rangeAHLSTAR APT end-suction single-stage centrifugal process pumps are used for demanding industrial applications to ensure process reliability, high efficiency and low operating costs. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR EPP/T high-temperature process pump rangeAHLSTAR EPP/T centerline supported end-suction single-stage centrifugal process pumps are designed to stand high temperature especially in demanding industrial hot liquid pumping applications. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR NPP/T non-clogging process pump rangeAHLSTAR NPP/T non-clogging end-suction single-stage centrifugal process pumps are designed for industrial large solids containing liquid or abrasive slurry applications to avoid plugging. The pump exceeds the requirements of ISO 5199.

-

Agitators, dynamic mixersSulzer SALOMIX™ and Scaba mixing and agitation technology offers a wide range of products for industrial applications. Side-mounted horizontal and top-mounted vertical agitators, dynamic chemical mixers, and tower and tank flow management products guarantee effective mixing and agitating processes.

-

Pump servicesReliable and efficient pump operation is critical for your business. Therefore you need a service partner that can respond fast and flexibly. Our pump services are second to none and provide solutions that help you to improve your processes and business performance.

-

Original pump spare partsOriginal spare parts machined to the correct tolerances and clearances give a perfect fit first time, every time. Our commitment to continuous improvement often allows us to supply parts with improved features, thus enhancing performance, extending equipment life, while reducing maintenance costs.

-

Service kitsWhen your equipment needs to be repaired you shouldn’t have to worry about spending valuable time searching for the right parts – or even worse, finding out that some small but vital parts are missing. With Sulzer service kits you get everything you need in one package.

-

Sulzer mechanical sealsSulzer mechanical seals are strong by design and have been proven very reliable in various pumping applications.

Industries

-

Chemical processingOur solutions for the chemical processing industry include pumping, separation and mixing, as well as services for rotating equipment and infrastructure. We offer experience in classical chemical, plastic, and pharmaceutical production as well as in processing renewable materials.

-

FertilizersOur pumps, mixers and agitators provide durability and reliability for fertilizers production as well as for corrosive and abrasive liquids and high gas content. Our specific industry experience also includes separation processes and servicing of pumps, compressors, turbines, and motors.

-

Mining and metalsLong experience and detailed knowledge of metals and mining applications with different raw materials makes Sulzer a reliable pump supplier for these industries.

-

BiofuelsBiofuels from renewable sources show great potential as sustainable transportation fuel. Based on our experience in demanding processes, we work with customers to develop advanced pumping, mixing, and distillation solutions for the production of biofuels, from pilot to commercial-scale installations.

Videos

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

Discover the power and performance of Sulzer's AHLSTAR process pumps

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

Interview about AHLSTAR process pumps

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

How to make a pump foundation the right way

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

How to position the pump and make grouting the right way

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

Careful commissioning of the pump plays a key role in the safe and reliable use of the pump

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

Connecting the pipes to the pump correctly is essential for ensuring the reliability of the pump

Talk or write to our experts to find your best solution.