- Lowest energy consumption

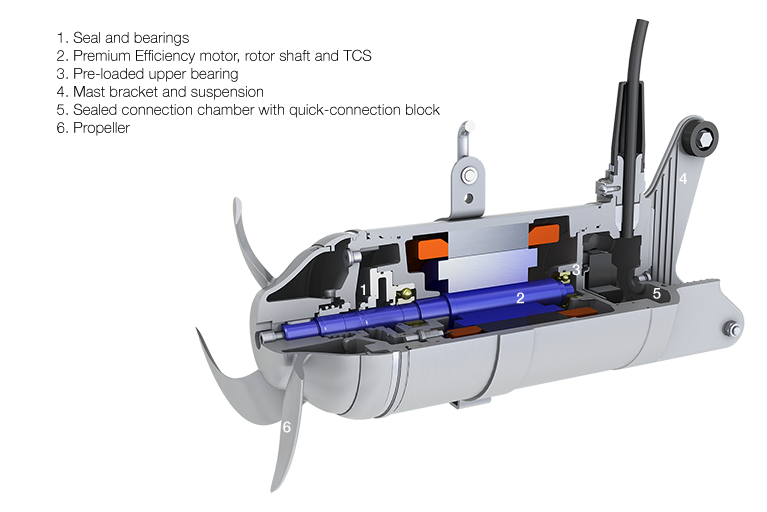

- Compact, water pressure-tight design

- Full stainless steel version available

- Shorter mixing times

- Minimal risk of motor overloading

- Superior reliability and long operating life

- Easy installation

- Small space requirements

- As an option, triple seal system with dual oil chamber enhances motor protection for full peace of mind

Submersible mixer XRW 210 to 900 for wastewater mixing

Submersible mixers for wastewater treatment

The XRW submersible mixer range is our premium range of submersible mixers with outstanding life-cycle economy and superior reliability. The range provides solutions to match mixing tasks in industry, municipal wastewater treatment plants and agriculture.

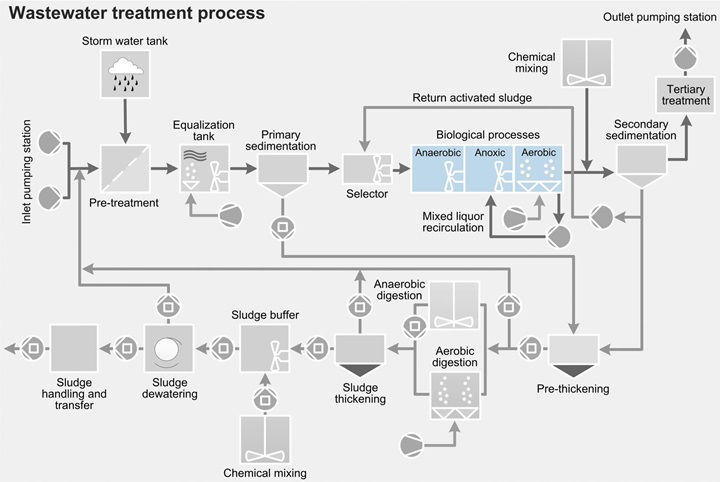

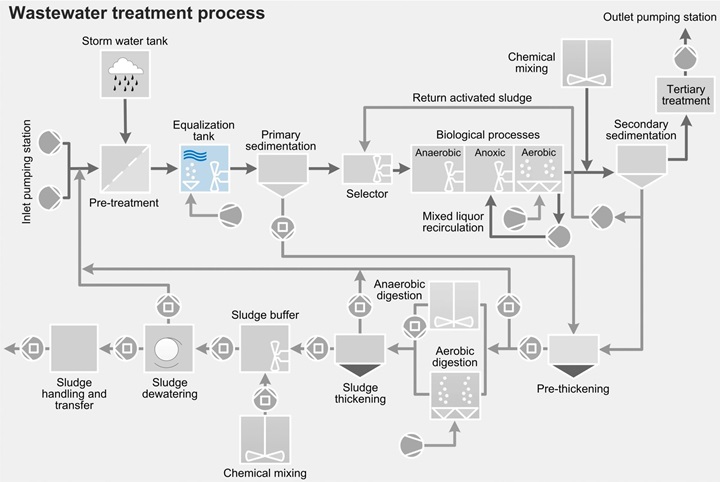

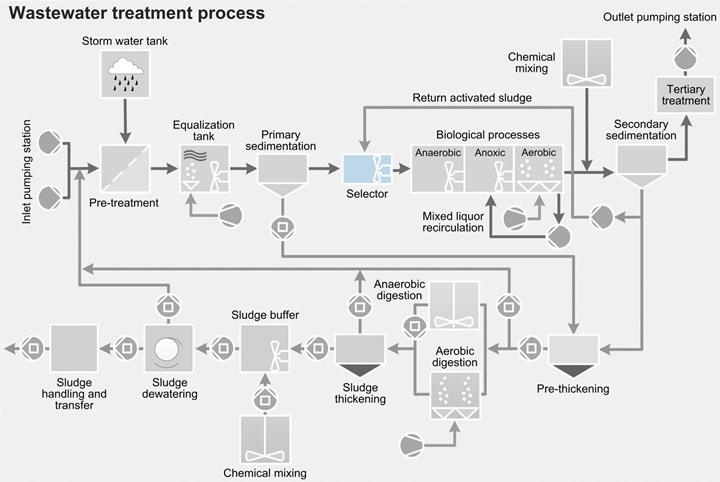

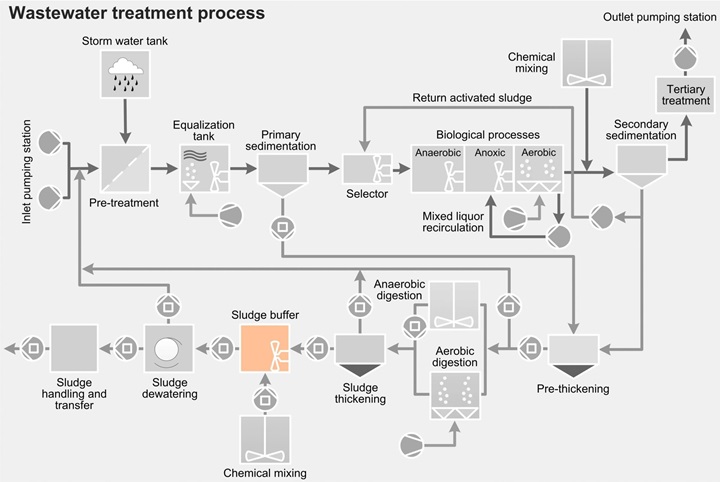

- Mixing and stirring applications in wastewater treatment plants and industrial areas

- Homogenization of highly-concentrated sewage sludge

- Homogenization and solid suspension

- Agitation in aerobic and anoxic mixing

- Sludge mixing and prevent floating crust

Main design features

- Optimized propeller designs ensure superior mixing performance

- Pioneering efficient motor options such as PMSM deliver low energy consumption

- Innovative self-cleaning propellers reduce maintenance requirements and improve reliability

- Smart features designed to inform preventative maintenance decisions

- Range of sizes ensures a cost-effective solution to suit all wastewater mixing applications

- Easy installation and retrofitting

Key characteristics

XRW range

| Mixing flow | 0.23 - 1.79 m3/s (3'650- 28'300 USgpm) |

| Propeller diameter | 210 - 900 mm (8 in. - 3 ft.) |

XRW 210-300

The high-speed submersible mixer range XRW 210 and XRW 300 are equipped with squirrel-cage induction motor of IE3 standard.

| 50 Hz (IE3) | 60 Hz (IE2 / IE3) | |

| Propeller diameter | 210 / 300 mm | 8 / 12 in (210 / 300 mm) |

| Motor power | 0.8 – 2.9 kW | 1.2 – 4.7 hp (0.9 – 3.5 kW) |

| Motor efficiency | up to 85% | up to 85% |

| Mixing flow | up to 0.23 m3/s | up to 3'650 USgpm (up to 0.23 m3/s) |

XRW 330, 400, 480 and 650

In the medium-speed range XRW 330, 400, 480 and 650, IE3-equivalent permanent-magnet motors provides the lowest possible energy consumption.

| 50 Hz (IE3 equivalent) | 60 Hz (IE3 equivalent) | |

| Propeller diameter | 330 / 400 / 480 / 650 mm | 13 / 16 / 19 / 26 in. (330 / 400 / 480 / 650 mm) |

| Motor power | 3 – 10 kW | 4 – 13.4 hp (3 – 10 kW) |

| Motor efficiency | up to 91% | up to 91% |

| Mixing flow | up to 0.83 m3/s | up to 13'200 USgpm (up to 0.83 m3/s) |

XRW 750 and 900

The medium-low speeds mixer range XRW 750 and XRW 900, are equipped with squirrel-cage induction motor of IE3 standard and a gear box as speed reducer.

| 50 Hz (IE3) | 60 Hz (IE3) | |

| Propeller diameter | 750 / 900 mm | 30 / 35 in. (750 / 900 mm) |

| Motor power | up to 22 kW | up to 33.5 hp (up to 25 kW) |

| Motor efficiency | up to 92.3% | up to 93% |

| Mixing flow | up to 1.79 m3/s | up to 28'300 USgpm (up to 1.79 m3/s) |