- Easily installed, stand-alone or portable with optional fixed installation

- Reduces odors and septic conditions

- Cost-effective installation

- Self-aspirating—no need for compressed air

- Operates irrespective of water level variation

- Very low noise level, no aerosol formation, and no sedimentation on the bottom, thus minimizing environmental effects

Aerator type ABS Venturi jet

Small size mixing and aeration

Based on the ejector principle, the Venturi jet aerator is an ideal solution for smaller tanks and small treatment plants. It provides cost-effective mixing and aeration in municipal and industrial wastewater applications, storm water retention tanks, and balancing tanks.

- Combined aeration and mixing of wastewater in small and medium-sized tanks

- Municipal and industrial wastewater applications

- Storm water retention tanks, and balancing tanks

Main design features

- Premium Efficiency IE3 motors from 1.3–18.5 kW

- Air throughput of 50– 550 Nm3/h (33–330 SCFM)

- Depth range of 1.5–6.0 m (5 – 20 ft)

Key characteristics

| Maximum water circulation | 500 m3/h (2,500 US gpm) |

| Maximum air throughput | 550 m3/h (330 SCFM) |

Applications

-

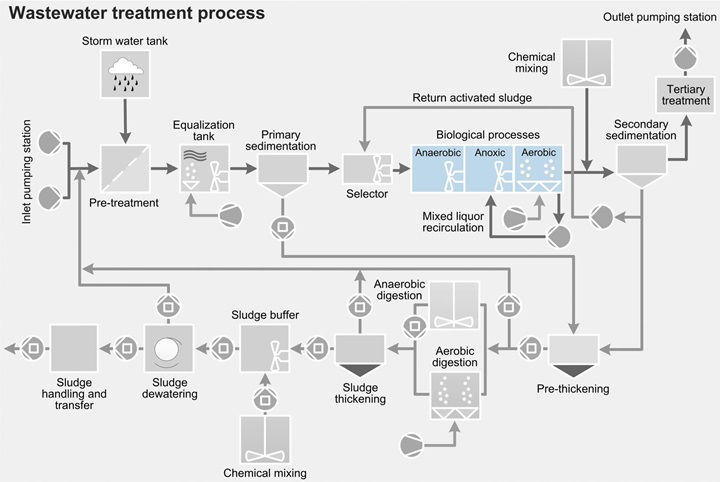

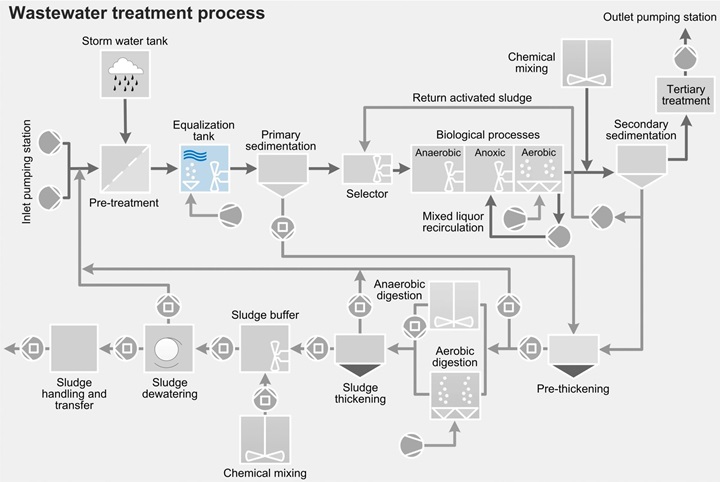

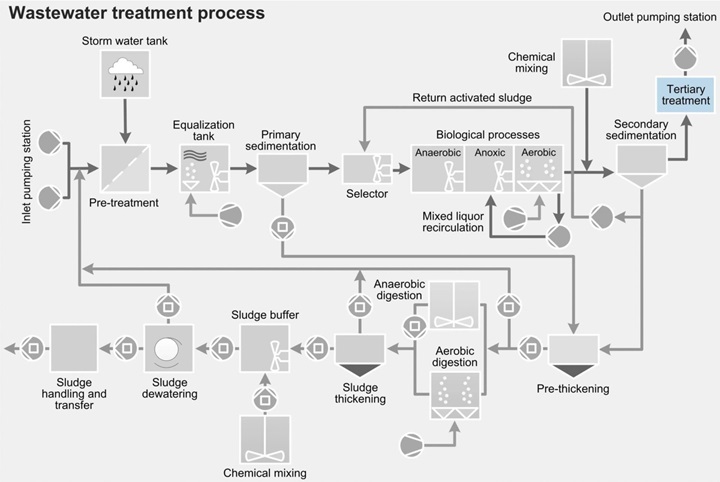

Biological processThe target of the biological process in wastewater treatment is to remove organic, biodegradable substances via the metabolism of microorganisms and related biochemical processes.

-

EqualizationThe task of mixing in the equalization process is to blend the wastewater in order to prevent sedimentation, stratification and odor formation. It may also be necessary to mix and homogenize wastewater streams that arrive from different sources. Because the water level in the equalization tanks varies significantly and can sometimes be very low, high demands are placed upon the mixers.

-

Lithium applicationsWith a comprehensive global reference base, broad range of reliable pumps and other process equipment and full line of lifecycle services Sulzer is the chosen equipment supplier for lithium processing. Our equipment is constantly developed for more efficient extraction and production of lithium-based compounds like lithium carbonate, lithium hydroxide, and lithium chloride.

-

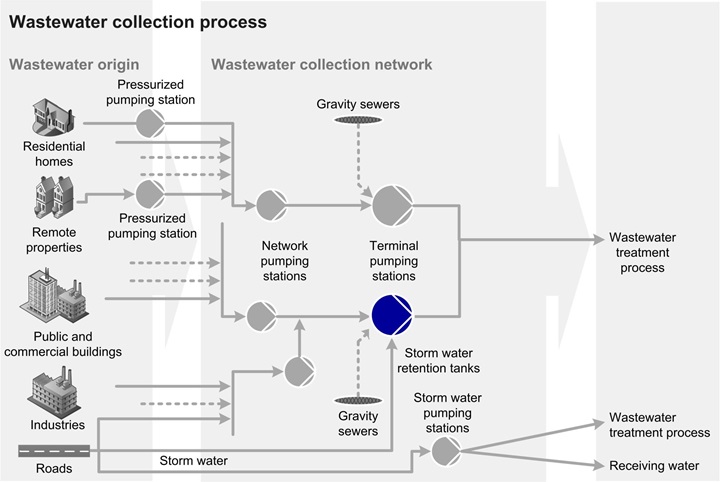

Storm water retention tankStorm water retention tanks act as a buffer during periods of heavy rainfall. This is increasingly important as areas become more developed, with hard surfaces such as roofs, roads and parking lots that cannot absorb the rainwater. When storm water retention tanks are implemented, gravity or pumps can be utilized to provide a reduced continuous flow into the sewer system. Sulzer expertise makes it possible to avoid peak hydraulic loads and to limit the stresses on existing sewer systems.

-

Tertiary treatmentTreated wastewater may occasionally require further treatment. Local discharge rules may pose strict limits that cannot be fulfilled by even the most effective process, or a higher quality of effluent may be requested for its reuse. When tertiary treatment is needed, various levels of filtration can be applied, including very fine filtration. Often, however, a final step of mixing and aeration is sufficient to achieve the target. When this is the case, Sulzer's submersible mixer types ABS XRW and RW can be used, along with submersible aerator type ABS TA–TAK and disc diffuser system types ABS PIK, DS and Sucoflow.

Case studies and articles

-

Delivering cost savings for wastewater treatmentAir is one of the most important elements used in wastewater treatment processes. Activated sludge systems require proper aeration of the wastewater to ensure the biological decomposition of organic compounds. However, while air costs nothing, the systems required to deliver it can account for 50 to 90% of the energy consumption of a plant. Therefore, the decisions made with respect to this equipment can have a significant impact on running costs.

-

Case studiesWherever fluids are pumped, mixed, controlled or applied, we are there. See how our solutions create value for customers and learn how we can make your pumping and mixing processes more efficient and profitable, safeguarding your production and ensuring lasting reliability.

Documents

Data sheets

Dimension drawings

Talk or write to our experts to find your best solution.