- Robust compact design

- Can be used in tanks of all shapes

- Hydrodynamic shape for optimum flow formation

- Drive unit optimized for mixing application

- Self-cleaning propeller blades ensure optimum operation with low energy input

- Concrete pedestal with innovative coupling system which allows the unit to be raised and lowered for inspection even in filled tanks

- Long operating life as the pedestal absorbs all dangerous vibrations

Flow booster type ABS SB

Economical with no compromise on reliability

The reliable, energy efficient low-speed submersible unit can be used in a wide range of applications in wastewater treatment plants. This is Sulzer’s standard range of low-speed mixers; economical without compromising on the reliable design.

- Suspension of activated sludge

- Flow generation in oxidation ditches

- Suitable for MBBR process (SB KA)

Main design features

- Patented mixer coupling system

- Energy-saving, self-cleaning propeller

- Integral motors ranging from 1.4 to 4.5 kW (1.9 to 6 hp) for gentle circulation and mixing

- Silicon carbide mechanical seal protected by a solids deflection ring

- Condition monitoring (temperature, water ingress)

- 100 000 h bearing lifetime

Key characteristics

| Maximum mixing flow | 4.3 m3/s (66,600 US gpm) |

| Maximum propeller diameter | 2,500 mm (8.2 ft) |

Documents

Brochures

Data sheets

Dimension drawings

-

Dimension Drawing - Lifting unit 5,0 kNpdfLanguages:

-

Dimension Drawing - SB KA (Multilingual)pdfLanguages:

Manual

Project design files BIM

-

BIM Model_Flow boster type ABS SB 1824rfaLanguages:

-

BIM Model_Flow booster type ABS SB 1825rfaLanguages:

-

BIM Model_Flow booster type ABS SB 2025rfaLanguages:

-

BIM Model_Flow booster type ABS SB 2523rfaLanguages:

-

BIM Model_Flow booster type ABS SB 2524rfaLanguages:

-

BIM Model_Flow booster type ABS SB 2525rfaLanguages:

Applications

-

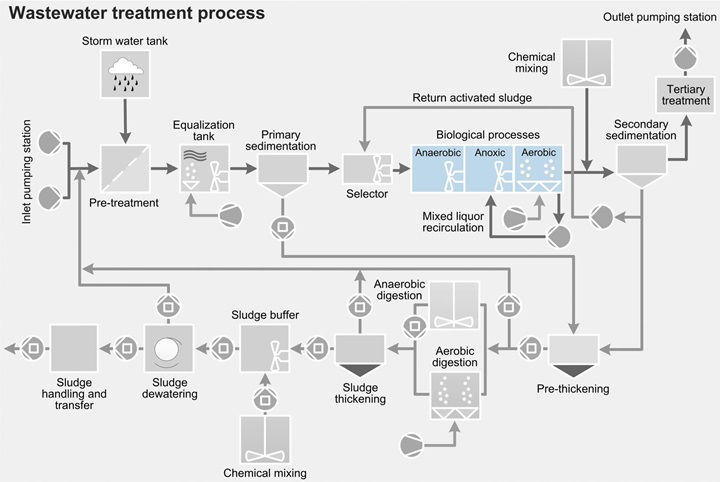

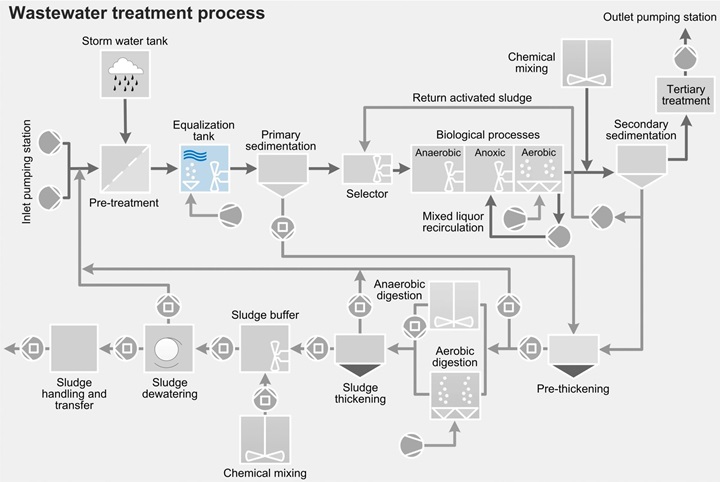

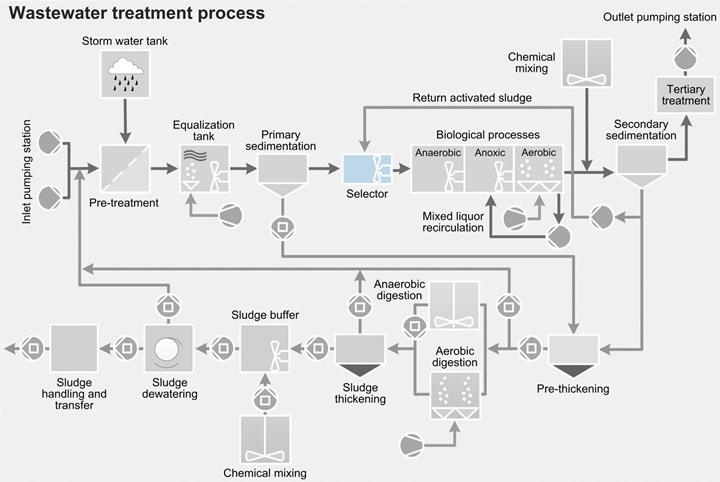

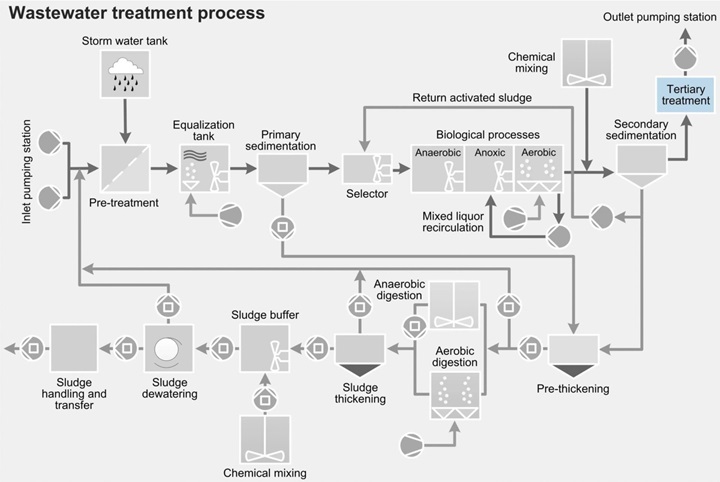

Biological processThe target of the biological process in wastewater treatment is to remove organic, biodegradable substances via the metabolism of microorganisms and related biochemical processes.

-

EqualizationThe task of mixing in the equalization process is to blend the wastewater in order to prevent sedimentation, stratification and odor formation. It may also be necessary to mix and homogenize wastewater streams that arrive from different sources. Because the water level in the equalization tanks varies significantly and can sometimes be very low, high demands are placed upon the mixers.

-

SelectorThe purpose of the selector tank is to control and limit the growth of filamentous bacteria, and then to enhance the sedimentation ability of the sludge. Sulzer provides a number of solutions for creating optimal conditions in the selector.

-

Tertiary treatmentTreated wastewater may occasionally require further treatment. Local discharge rules may pose strict limits that cannot be fulfilled by even the most effective process, or a higher quality of effluent may be requested for its reuse. When tertiary treatment is needed, various levels of filtration can be applied, including very fine filtration. Often, however, a final step of mixing and aeration is sufficient to achieve the target. When this is the case, Sulzer's submersible mixer types ABS XRW and RW can be used, along with submersible aerator type ABS TA–TAK and disc diffuser system types ABS PIK, DS and Sucoflow.

Talk or write to our experts to find your best solution.