- Easy to install and freestanding on the bottom of the basin—no need to empty the basin for installation

- Wear-resistant and long lifetime

- Very low noise level, no aerosol formation, and no sedimentation on the bottom, thereby minimizing environmental effects

- Self-cleaning

- High Standard Oxygen Transfer Rate (SOTR) and Standard Aeration Efficiency (SAE) values

- Excellent solids suspension capability

Submersible aerator type ABS XTA XTAK

All in one aerator

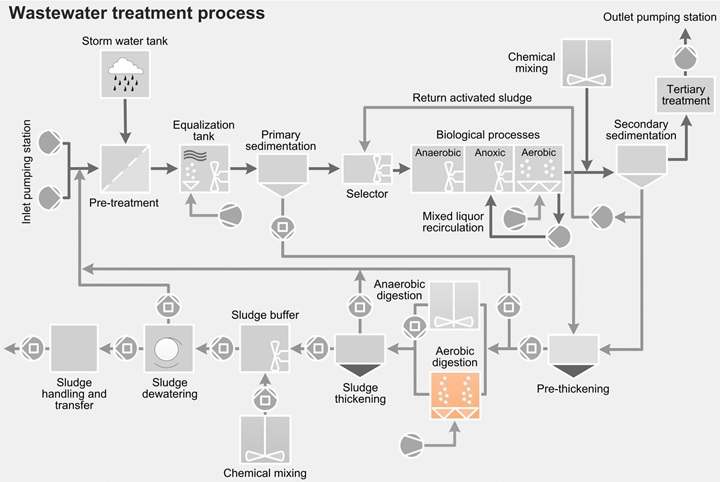

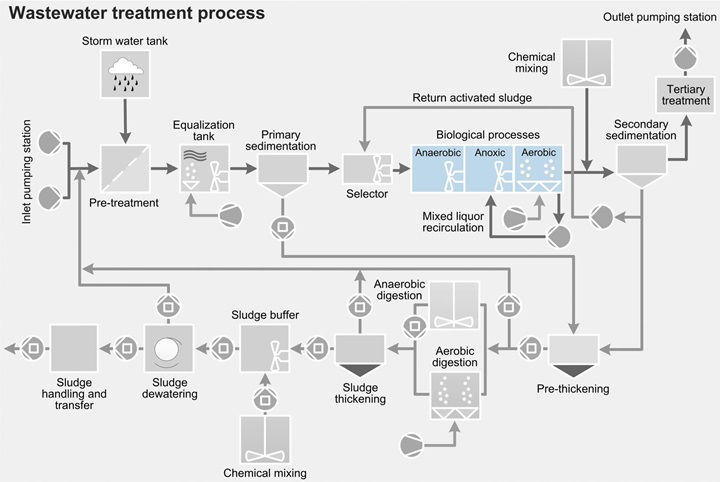

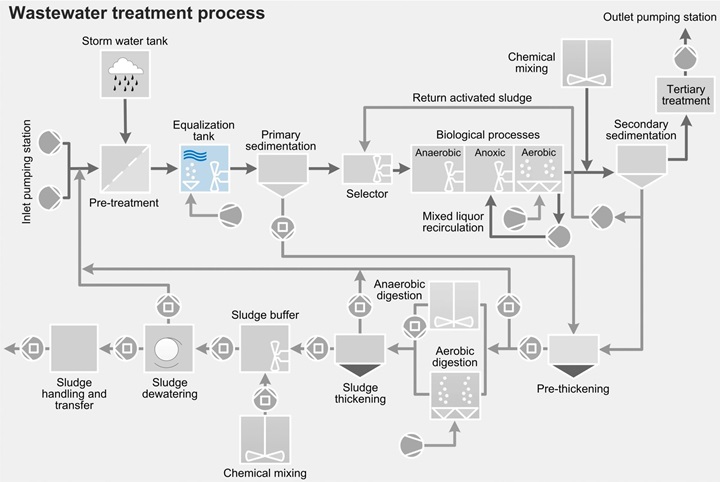

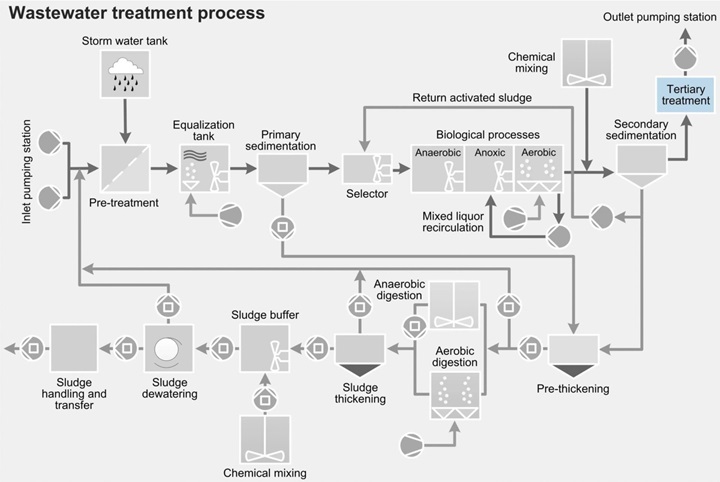

The XTA and XTAK are self-aspirating submersible aerators for wastewater and water treatment in municipal and industrial plants. The main areas of application are mixing and equalization tanks, activated sludge tanks, SBR, and sludge storage tanks.

- Activated sludge basins and Sequencing Batch Reactors (SBR), providing aeration and mixing in one unit for degradation of biomass load

- Mixing and equalization basins providing uniform wastewater loading to downstream processes, and eliminating odors

- Sludge storage and stabilization, providing odor control as well as oxidation of sludge

- Flotation of oil and grease

- Additional aeration

- Neutralization of alkaline wastewater with CO2 or flue gas

Main design features

The XTA/XTAK self-aspirating aerator is a submerged aerator, mixer, blower, and pump combined in a single unit. It has the power to meet the most demanding oxygen transfer and mixing requirements.

The XTA aerator is available in a full range of Premium Efficiency IE3 motors from 3 to 75 kW and with an oxygen transfer of up to 80 kg O2/h.

The main areas of application are mixing and equalization tanks, activated sludge tanks, SBR, and sludge storage tanks at water depths from 2 to 9 m (7–30 ft).

Key characteristics

| Oxygen transfer | up to 80kg O2/h (176 lbs O2/h) |

| Motor range | 3–75 kW (100 hp) |