-

Phosphate fertilizersOur pumps and agitators provide durability and reliability in severe applications and our high-efficiency compressors reduce energy consumption.

-

Mining and metalsIn the real world time is money, and worksites have no time for unwanted water. Sulzer has the solutions in a complete pump range for reliable dewatering.

-

ChemicalsSulzer improves quality, capacity, and energy efficiency with its advanced technologies and services for separation processes; including distillation, absorption, evaporation, extraction and crystallization. Our pumps, mixers, and agitators cover the specific requirements in chemical processes.

-

Waters in fertilizers complexesOur dedicated pumps, agitators, mixers and aeration equipment provide efficiency, reliability and durability in all water and wastewater applications.

Molten sulfur, sulfuric acid and oleum

Proven and reliable equipment for the sulfur industry

Sulfur (S) is the essential constituent of one of the most common chemicals produced industrially, sulfuric acid. Its output volumes are almost infinites. The main consumers are in the phosphate, chemical and metals industries.

Sulfuric acid is produced from various sources and via several processes. From the production of molten sulfur in the O&G industry to the production of sulfuric acid in fertilizer, metals, and chemical complexes, we are present in all steps of the process with dedicated and proven equipment.

Our coverage of the sulfur industry also includes a complete range of rotating equipment for water supply, water treatment, cooling water circulation and other specific applications linked to power generation.

We have a dedicated range of equipment for key applications in the production and handling of molten sulfur: heat jacketed vertical line-shaft pumps as per API (VS4) or manufacturer standard, heat jacketed horizontal pumps, and vertical agitators for melting and intermediate molten sulfur tanks.

Your applications:

- Melting/pump/storage tank agitator

- Filter feed pump

- Filter precoat pump

- Burner feed pump

- Polishing pump

- Storage tank circulation pump

- Sulfur loading pump

With a long experience and worldwide references in sulfuric acid plants, we can provide you with our dedicated and proven VAS vertical turbine pump for sulfuric acid tower circulation. For other applications, we have horizontal process pumps, and vertical cantilever or line-shaft pumps for sump applications.

Your applications:

- DT/IAT/FAT circulation pump

- Oleum tower circulation pump

- Product acid pump

- Oleum transfer pump

- Acid transfer pump

- Drain pump

- Acid/effluent sump pump

Heat recovery is a must for producers targeting the highest overall efficiency of the plant. Several technologies exist requiring pumps that are able to handle very hot sulfuric acid, and in some cases molten salt pumping may also be needed. We developed a specific design for our VAS pump for very hot sulfuric acid applications, and we have extensive experience in molten salt vertical pumping applications.

Your applications:

- Heat recovery tower circulation

- Molten salt circulation

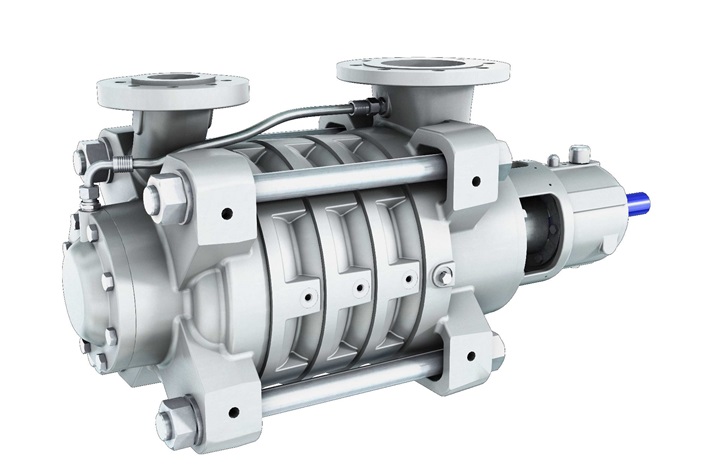

The production of sulfuric acid requires a large amount of water either as a feedstock for the sulfuric acid itself, or for the various applications linked to flushing, cooling and power generation. We have a complete range of standard and well-performing equipment including horizontal and vertical pumps, either single-stage or multi-stage, and axial and radial split pumps for either large flow or high head applications.

Your applications:

- Cooling water circulation pump

- Water feed pump

- Scrubber circulation pump

- Effluent sump pump

- Condensate pump

- Boiler feed pump