-

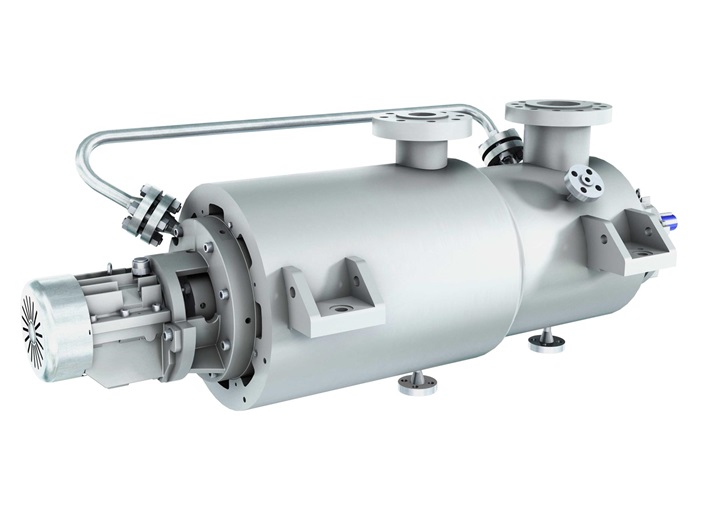

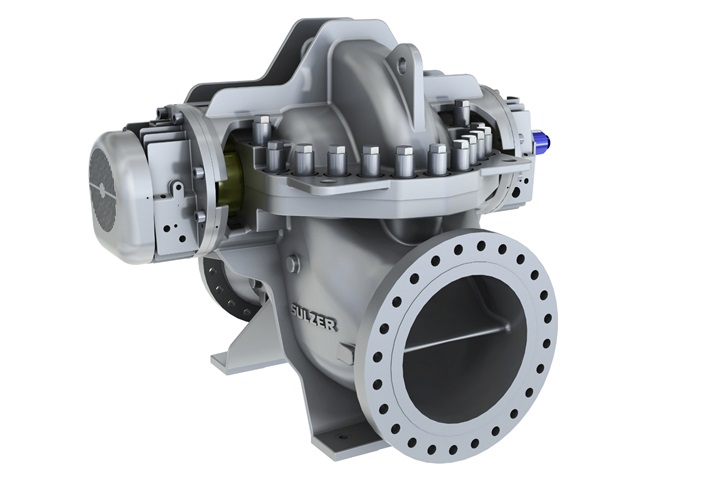

CP volute style barrel pumpCP ISO 13709 / API 610 Type BB5 radially split barrel casing pumps are used in both high-pressure oil production and high-temperature refinery applications.

-

GSG-BFP diffuser style barrel pump for feedwater applicationsThe GSG-BFP is a BB5 type pump designed for feedwater applications in fossil and industrial power plants.

-

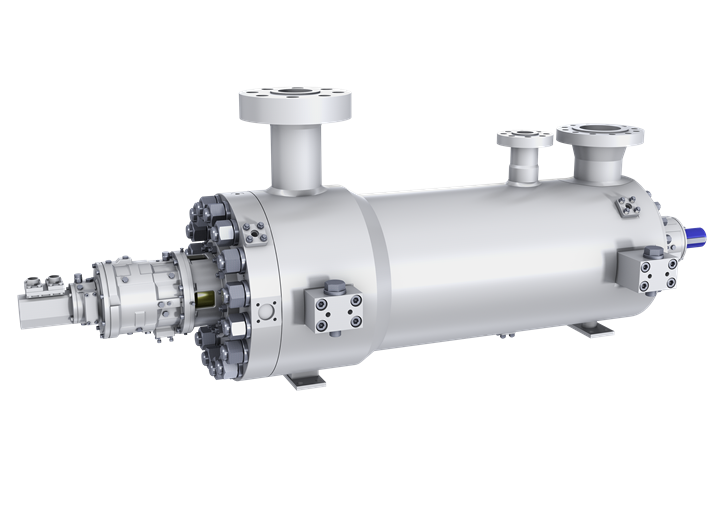

HPcp barrel casing pumpHPcp ISO 13709 / API 610 Type BB5 radially split barrel pumps are used for water injection, offshore crude oil shipping, and remote pipeline services. The Sulzer HPcp pump is the leader in ultrahigh pressure applications.

-

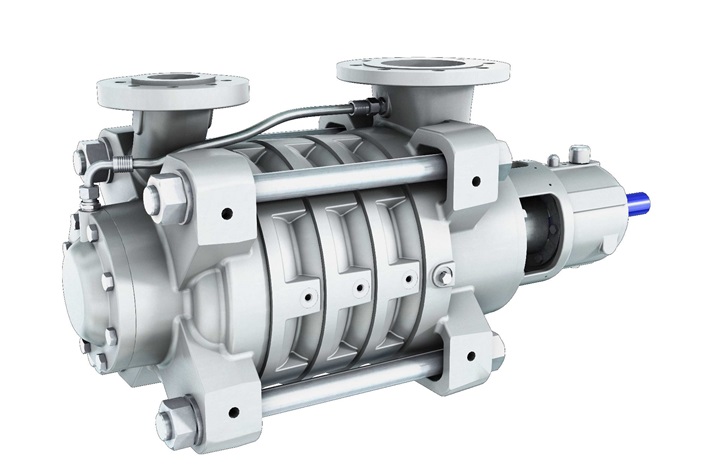

MBN multistage ring section pumpThe MBN pumps are ideal for use in high-pressure applications. They have a big variety of nozzle position options, thus providing flexibility during installation and simplifying the piping design.

-

MC high pressure stage casing pumpM-series pumps have a modular design thus allowing Sulzer to find the most efficient solution to meet customer requirements.

-

MD high-pressure stage casing pumpBoth investment costs and lifecycle costs are taken into consideration when designing the optimum possible pump as an optimized hydraulic design guarantees maximum efficiency.

-

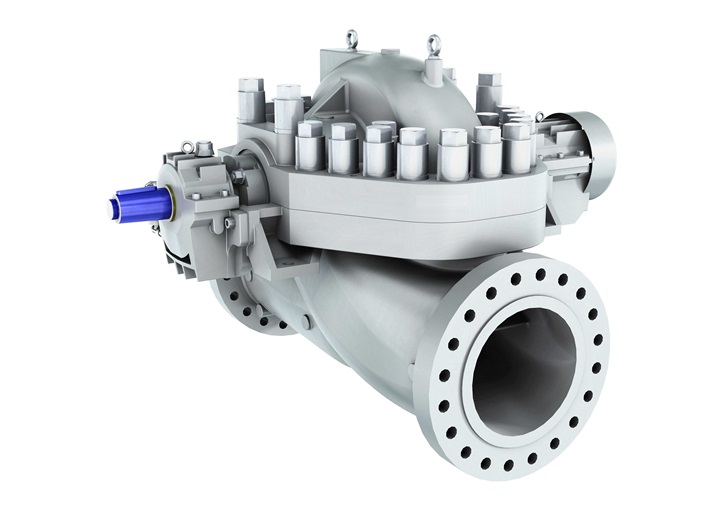

HSA axially split single stage between bearing pumpThe HSA API 610 (ISO 13709) Type BB1 is an axially split, single stage, horizontal, double suction, between bearing pump. The Sulzer HSA product range is ideal for long term continuous running services in refineries and pipelines. Its robust casing and custom hydraulics are specifically designed to ensure maximum availability and reduced total life cycle costs. The HSAv with its vertical shaft is used offshore where deck space is limited.

-

HSB axially split single stage between bearing pumpThe HSB API 610 (ISO 13709) Type BB1 is an axially split, single stage, horizontal, between bearing pump. Many HSB pumps are in service on crude oil pipelines in many parts of the world. Its robust casing and custom hydraulics are specifically designed to meet project requirements.

-

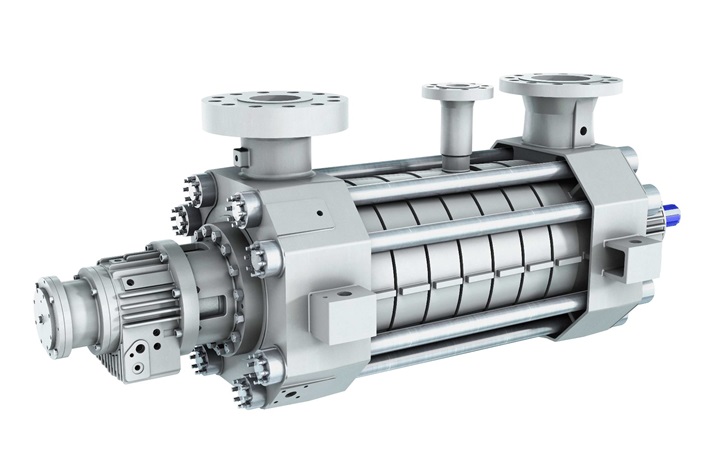

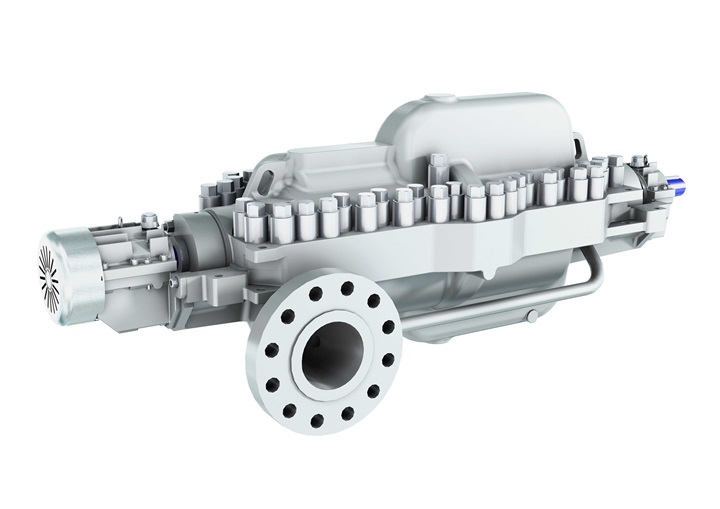

MSD axially split multistage pumpThe MSD pump has the broadest hydraulic coverage of any BB3 type multistage pump in the market. There are over 10 000 MSD pumps installed in product pipelines, boiler feed, water injection and even nuclear safety-related services around the globe.

Utilities for refining

Efficient solutions for optimum plant performance

As a global company with high focus on efficiency and environmental solutions, Sulzer can deliver cost efficient and reliable utility solutions backed up by a network of over 100 service centers across the globe.

Our full range of pump products for boiler feed, condensate extraction and cooling water, combined with our continued expansion into water treatment systems provide customers with a one-stop, end to end solution.

Utilities process

Refineries require a comprehensive array of supporting utilities to process crude oil into refined product.

Large amounts of electricity are required to provide power to equipment, lighting, heating and computer systems. This electricity may come from the main grid however it is often generated directly from a captive power plant dedicated to the plant.

Large amounts of purified water are required to support steam generation, heat-exchangers and cleaning processes. Water must be treated after use to remove any contaminants or residual heat before any discharge into the sea or municipal water system.

Utilities are critical life support to the refinery, reliability and efficiency of these systems are of the upmost importance to maximize uptime and minimize operating cost.