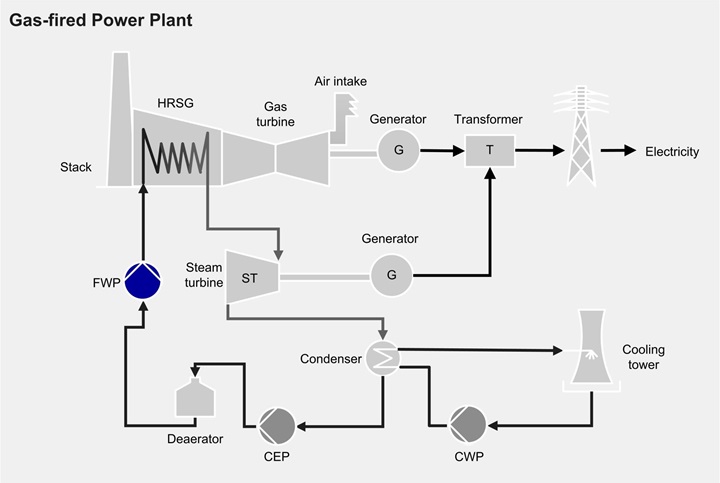

- Modular hydraulics for high efficiency in a wide range of operating conditions as required for gas-fired combined-cycle power plants

- Optimized design for thermal conditions as applicable in gas-fired combined-cycle power plants

- Centerline mounted with large branch sizes for optimized inlet flow, low noise level, and higher allowable forces and moments

- Unaffected by rapid temperature variations and therewith highly suitable for gas-fired combined-cycle power plants where frequent start-stop operation is specified

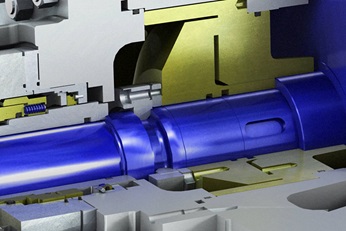

- Stiff shaft design for critical speeds above the maximum operating speed

- Multiple screws mechanical tensioners are used on large sizes to allow simpler tightening and loosening

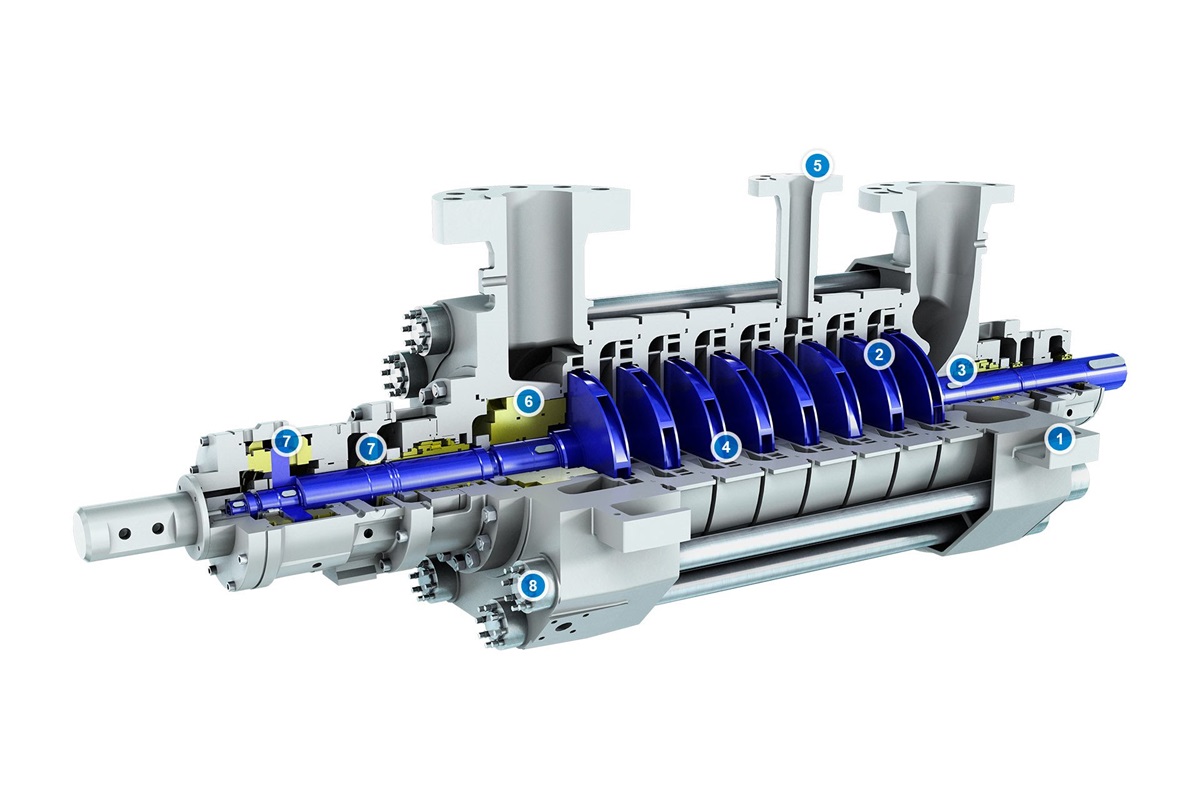

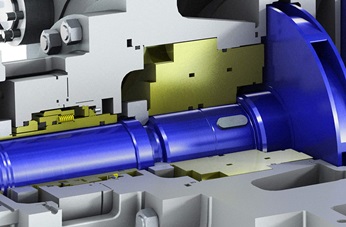

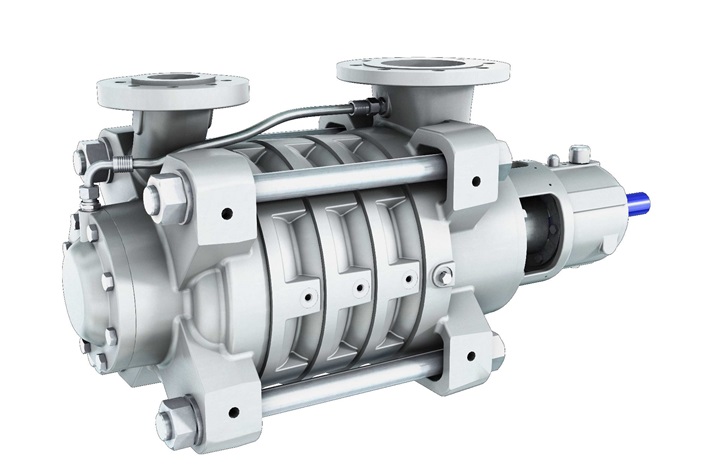

MD high-pressure stage casing pump

Customized high-pressure pump with clever modular design

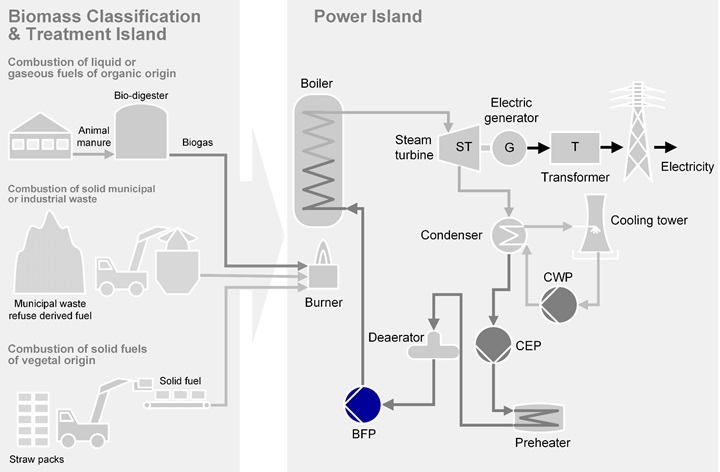

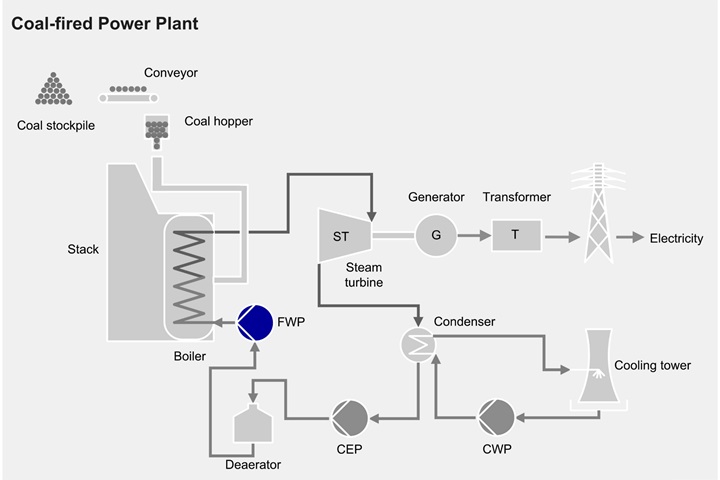

The MD pumps are suitable for pumping clean or slightly polluted, hot or cold water. They have been specifically designed for application such as:

- Main boiler feedwater pump in captive, independent, biomass, and industrial power plants

- Main feedwater pump in gas-fired combined-cycle and concentrated solar power plants

- Start-up boiler feedwater pump in utility thermal power plants

- High-pressure water pump in general industry

1. Casing support

Centerline mounting absorbs high forces and moments. Pre-warming not required

2. Impeller

- Several hydraulic sets per pump size guarantee high efficiencies and low operating costs over a wide operating range

- Low Net Positive Suction Head Required (NPSHR) first stage; double suction first stage can be provided for selected sizes

3. Shaft

Transmits the required torque and minimizes deflection

4. Rotor design

Stacked rotor with staggered keyways to transmit torque

5. Intermediate take-off

Reduces head losses; large take-off flow is available on certain sizes

6. Hydraulic thrust balancing system

- Balance drum and axial thrust bearing designed for long life under extreme operating conditions

- Balance disc and lift-off device (mechanical and magnetic) available for frequent start-stop operation

7. Bearings and lubrication

- Sleeve radial and tilting pad thrust bearings are optional for high power and thrust duties

- External lube oil supply can be provided for high power and thrust duties

8. Discharge casing and nuts

- Mechanical tensioners allow simple tightening and loosening and provide high security against loosening (no special tooling required)

- High-pressure version available up to 350 bar MAWP (5'080 psi) and able to accept downward thermal transients

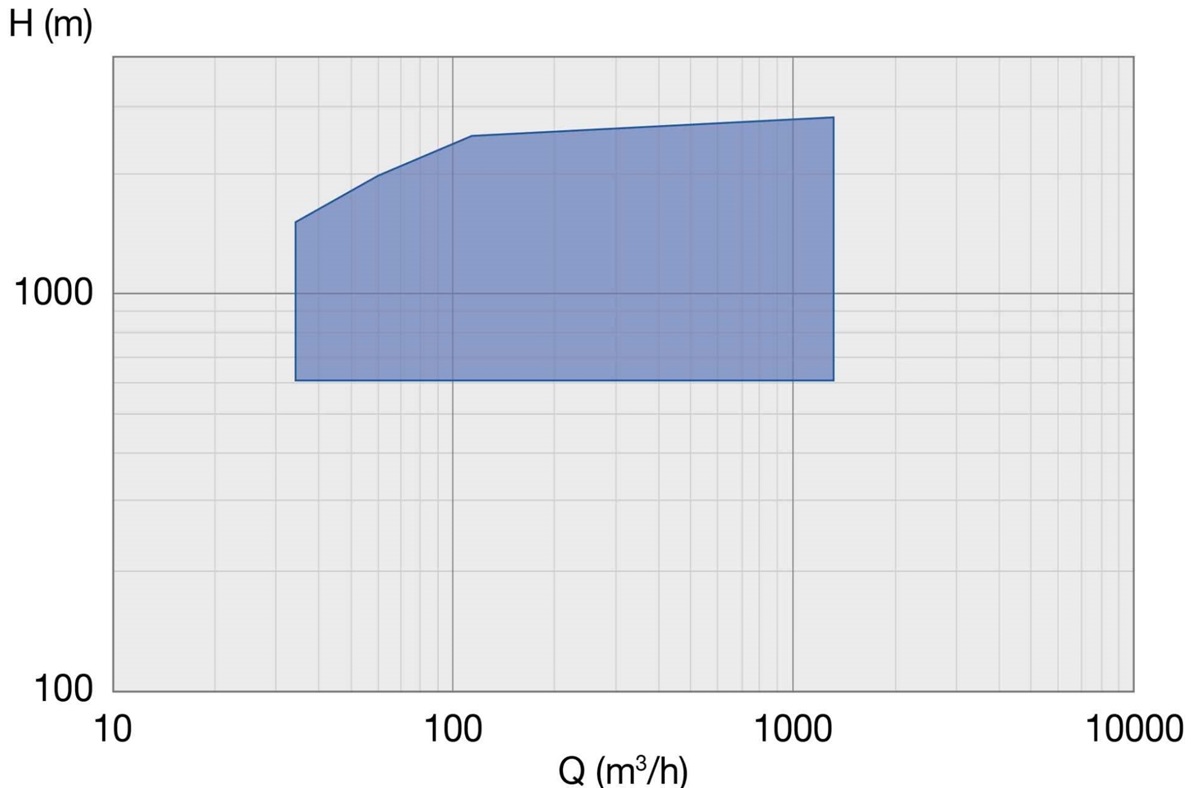

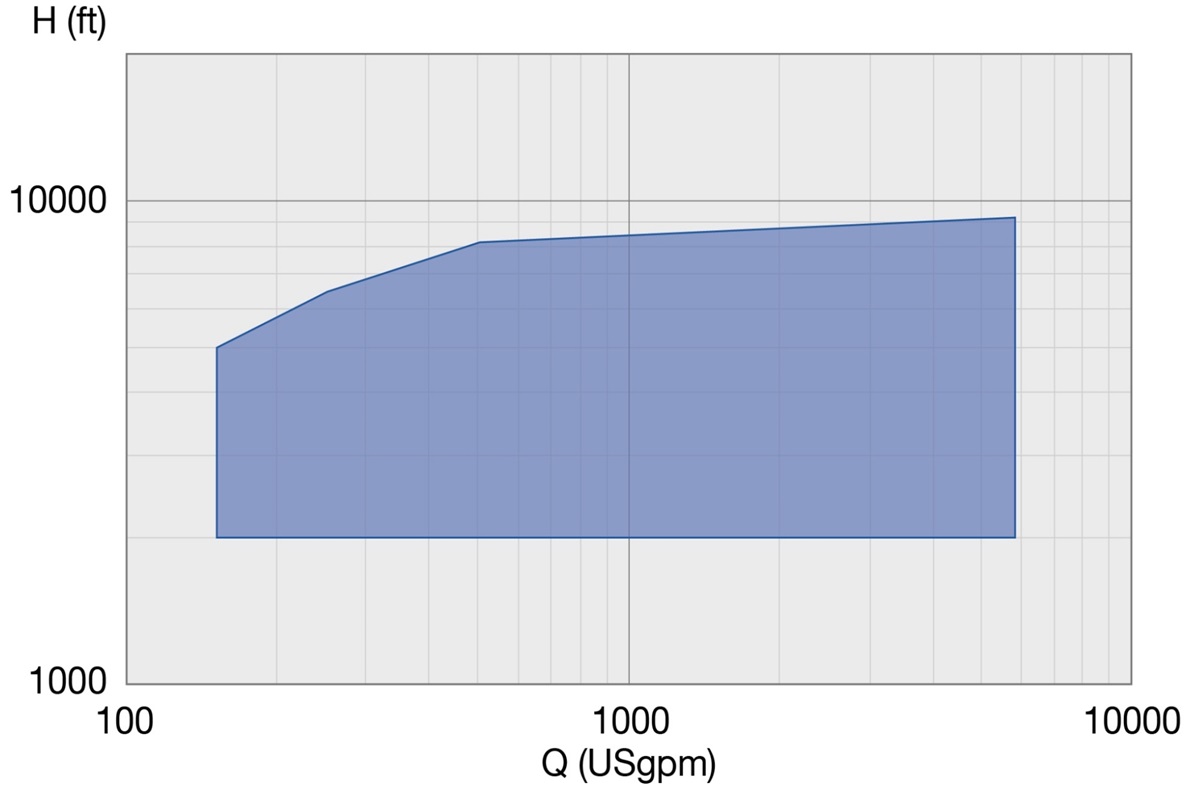

| 50 Hz | 60 Hz | |

| Discharge sizes | up to 200 mm | up to 8 in |

| Capacities | up to 1,200 m3/h | up to 5,300 US gpm |

| Heads | up to 2,800 m | up to 9,200 ft |

| Suction pressures | up to 50 bar | up to 725 psi |

| Discharge pressures | up to 350 bar | up to 5,080 psi |

| Temperatures | up to 210°C* | up to 410°F* |

| Pump part | Material |

| Suction stage and discharge casings | Chrome steel |

| Impellers | Chrome steel |

| Shaft | Chrome steel |

| Balancing system | Chrome steel |

Balance drum

The balance drum device carries the major proportion of the hydraulic thrust. The drum diameters are chosen to minimize the thrust at normal operating point. The residual and additional thrust loads occurring above/below the normal operating point are carried by the thrust bearing, typically a tilting pad.

The balance drum is suitable for:

- Pumps operating at the end of the curve, up to 120% of the best efficiency point

- Frequent start-stop applications thanks to nearly wear-free device

Balance disc

With a balance disc, the axial force is completely compensated; no axial thrust bearing is required. Due to the smaller balancing leakage flow, total efficiency of the pump is higher than the pump efficiency with the balance drum design.

For pumps with frequent start-stop operations, the installation of a mechanical or magnetic (PERMAVORTM) lift-off device is recommended.

Mechanical or magnetic (PERMAVORTM) lift-off devices

Advantages:

- Prevent touching and wear of disc/counter disc operation at low speed such as start-up and shut-down

- Self-controlling passive systems

- Reduce load on balance disc under normal operation

- Offer long service life

High pressure design

- Design pressure (MAWP) up to 350 bar

- Extended flow and head range meet the requirements of the steam-water cycle for the latest heavy-duty high-output gas turbine developments

- Advanced design to accommodate steep thermal transient conditions (upwards and downwards)