- Compact design

- High efficiency

- High reliability

- Easy handling

Submersible recirculation pump type ABS XRCP

Streamlined designs for large flows

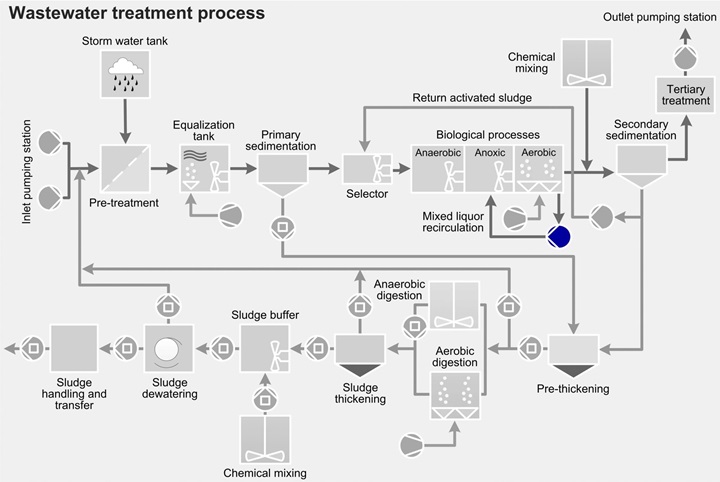

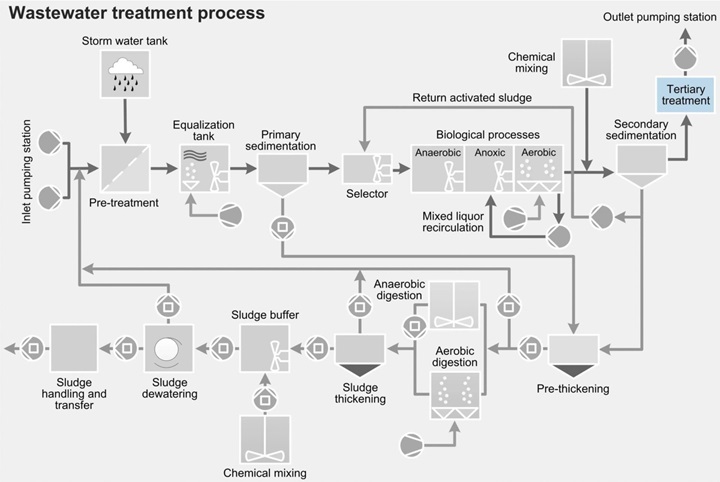

The XRCP is Sulzer’s premium range of recirculation pumps, specifically designed for efficient pumping and recirculation of activated sludge in the denitrification/nitrification process of a wastewater treatment plants. These compact and easy-to-handle pumps are equipped with Premium Efficiency motors and designed for large flows and low heads. Compared to conventional axial flow pumps, recirculation pumps do not require expensive structures in the tank, such as inflow chamber and a large rising pipe.

- Recirculation of activated sludge in wastewater treatment plants

Main design features

- Easy installation

- Self-cleaning propeller

- As an option Triple seal system with dual oil chamber enhance motor and gearbox protection for full peace of mind

- Premium-efficiency IE3 motors or equivalent

- Seal monitoring using multiple sensors

- Thermo-Control System (TCS) provides timely warnings and auto switch-off

The unit is lowered along a guide tube and connected to the pipeline by an automatic coupling system.

Key characteristics

| 50Hz/60Hz | |

| Max. flow | 1.68 m3/s (25'680 USgpm) |

| Max. head | 1.63 m (4.7 ft.) |

| Discharge sizes | DN 250-800 (10"-31") |