- Valves oriented parallel to liquid flow direction

- No liquid flow under valves

- Minimized weeping due to lateral vapor release

- Improved turndown ratio compared to round valves

- Improved efficiency/capacity profile compared to conventional round valve trays

- Wide legs and lack of valve rotation reduce damage and wear

- The rectangular shape of the legs prevents spinning and wearing

- Design allows for top side valve replacement

- Available range of valve lifts and weight allow for optimal design

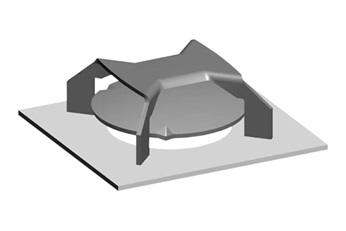

- The unique “umbrella” shape of UFM family offers several key advantages:

- Reduces vertical jetting momentum of vapor, minimizing entrainment and enhancing capacity

- Increases contact area between vapor and liquid on tray deck, improving mass transfer efficiency

- Minimizes pressure drop while maximizing the operating range

Floating valve trays

Sulzer's unique floating valves for higher efficiency and capacity

- Main fractionators of refineries

- Gas concentration columns of refineries

- Light end columns of petrochemical plants

- LNG / NGL fractionation columns

- Absorbers and regenerators of gas sweetening plants

- Biodiesel / Fatty acids

- Olefins / EOEG / BDO / Butylene / Butadiene

- Phenol / Methanol / Solvent Recover

- Sour water stripper

UFM™ Max is a large-size high performance floating valve, it maximizes the hydraulic capacity of a fractionation tray while minimizes the investment.

Key benefits

- Drop-in solution for capacity increase up to 18% in existing column

- Lower CAPEX, reduce column diameter up to 10% lead to saving in material and smaller footprint

- Wide operating range, maintaining good efficiency even at turndown lead to reliable plant performance

- Enhanced separation efficiency, contributing to energy saving and reducing OPEX

- Designed for easy installation and safe inspection access

The unique “umbrella” shape of UFM family offers several key advantages:

- Reduces vertical jetting momentum of vapor, minimizing entrainment and enhancing capacity

- Increases contact area between vapor and liquid on tray deck, improving mass transfer efficiency

- Minimizes pressure drop while maximizing the operating range

Fields of application

UFM Max trays are mainly used in applications requiring both high performances and a wide operating range. It is well-suited for a broad range of applications that typically utilize floating valves, including:

- Fractionation columns in gas processing

- Light ends columns in refinery and petrochemical plants

- Distillation columns operating in varies vapor/liquid loads such as solvent recovery, sour water stripper, fatty acids fractionation, biodiesel and methanol columns

UFM™ is a floating valve which maximizes the hydraulic capacity of a fractionation tray and the operating range.

Functional features

- UFM is a mini-floating type of valve

- UFM provides up to 20% additional capacity compared to conventional sieve and valve trays

- UFM has at least the same operating range as a conventional floating valve

- Minimizes weeping due to lateral vapor release

- UFM valves are oriented parallel to liquid flow direction

- The rectangular shape of the legs prevents spinning and wearing

- UFM is equipped with four dimples to prevent sticking to the tray deck and to enhance fouling resistance

- UFM can be combined with upgraded downcomer technology to achieve maximum tray performance and turndown

- UFM has the highest efficiency among all Sulzer valve trays

Fields of application

UFM trays are mainly used in applications requiring both high performances and a wide operating range, particularly:

- High-pressure columns in gas fields

- Light ends columns in refinery and petrochemical plants.

The unique rectangular-shape sets the BDH™ apart from the conventional valves. The BDH is oriented parallel to the liquid flow direction, providing lateral vapor release and a closed upstream edge to minimize weeping. This contributes to an improved efficiency/capacity profile compared to conventional round valves.

Further advantages of the rectangular valves:

- Improved liquid flow along the flow path on the tray deck

- Wider operating range

- Robust mechanical design due to wide legs

- Anti-rotating which reduces wear and tear

Round valve

We offer round valve trays for replacement or whenever customers request it. There are two types of round valves available: conventional and caged valves.

Available conventional valve types

- RV1 for flat decks

- RV4 for decks equipped with venturi holes for lower pressure drop

Available caged type valves

- RC1 for flat decks

- RC4 for decks equipped with venture holes for lower pressure drop

Contact our Separation technology team directly