-

Ejector for pumpSulzer ejector is suitable for all horizontally installed pumps. It offers an easy solution for enabling fast, reliable and fully automated priming for retrofitting existing or new installations. It also includes a full automation package.

-

SNS end-suction single-stage process pump rangeThe SNS end-suction pump has been designed to exceed the highest energy efficiency regulations across all industries and also the design requirements of ISO 5199 international standard. The innovative design makes this centrifugal pump more reliable while significantly reducing total cost of ownership.

-

CPE ANSI process pumps range (ANSI/ASME B73.1)CPE ANSI pumps are specifically designed to exceed the strictest energy regulations for all industries as well as the requirements of ASME B73.1. With revolutionary hydraulics and high efficiency, they offer the lowest life cycle costs.

-

SIL inline process pump rangeHigh-efficiency SIL inline single-stage centrifugal pumps are developed to meet the process requirements in various general and industrial applications. Inline design with integrated motor construction makes this process pump compact and easy to install.

-

AHLSTAR A process pump rangeAHLSTAR A end-suction single-stage centrifugal process pumps are used for demanding industrial applications to ensure process reliability, high efficiency and low operating costs. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR APT process pump rangeAHLSTAR APT end-suction single-stage centrifugal process pumps are used for demanding industrial applications to ensure process reliability, high efficiency and low operating costs. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR EPP/T high-temperature process pump rangeAHLSTAR EPP/T centerline supported end-suction single-stage centrifugal process pumps are designed to stand high temperature especially in demanding industrial hot liquid pumping applications. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR WPP/T wear-resistant process pump rangeAHLSTAR WPP/T wear-resistant end-suction single-stage centrifugal pumps are designed for abrasive and erosive pumping applications, such as lime milk and mud, and coating pigments. The pump exceeds the requirements of ISO 5199.

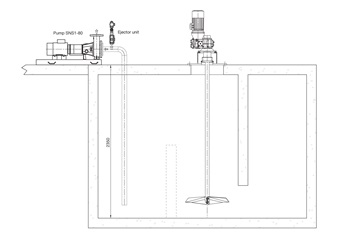

Sulzer ejector for fully automated sump pumping

Reliable and cost-effective sump pumping with Sulzer’s ejector

The alternatives were to use a cantilever pump, a submersible pump, a self-priming process pump or a process pump with an ejector

The challenge

We needed to find the optimal solution for sump pumping in terms of reliability, service friendliness, efficiency and investment costs to maximize the benefits for the customer.

The customer wished to use a standard process pump for sump pumping to enable the use of the same spare parts as for the process pumps in the other applications of the mill.

The solution

We concluded that our SNS process pump provided with an ejector was clearly the best alternative for this purpose – both energy efficient and cost competitive. We were able to select from a variety of pump sizes and stated that the SNS1-80 pump was performing very efficiently, and that the ejector did not consume energy during the normal pumping process. In the mill, there was pressurized air available for the ejector.

The wastewater pit pump works intermittently, so priming is needed multiple times per day. The automation package controls the valves accurately and performs the priming smoothly. No problems or failures have occurred. Priming with an ejector is efficient, reliable and fast.

Sump pumping has never been as easy as with a standard process pump equipped with an ejector. Priming has never failed, and it is very fast.

Juha Ottelin

Area Sales Manager at Sulzer in Finland

Customer benefit

- The complete pump unit and the ejector, including the automation package, were easy and fast to install and take into use.

- The ejector makes sump pumping easy, fast, reliable and cost effective.

- The investment cost is low.

- The solution is service friendly because the sump pump uses the same spare parts as the other process pumps in the mill.

| Segment | Pulp, paper and board industry |

| Application | Wastewater pit pumping |

| Pump | SNS1-80 end-suction single-stage pump |

| Capacity | 10 l/s |

| Head | 5.5 m |

| Seal | double mechanical seal |

| Rotational speed | 1’500 rpm |

| Ejector | Ejector unit with automation package |

Your expert