Quick turnaround motor

rewind and overhaul

|

Location |

UK North Sea |

|

Industry |

Oil & Gas |

|

Key Services |

The Challenge

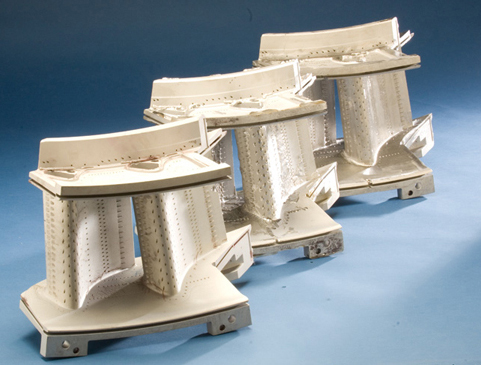

Heating Medium Motor

The problem:

- The platform has two Heating Medium Pump Motors with one being required to be functioning at any one time.

- The machine had developed high partial discharge which affects the insulation integrity of the machine while it is in operation, this led to reliability concerns as well as the poor general exterior condition of the machine.

- When one machine is removed from service for maintenance the platform is at single point failure, therefore it is critical they have two units available at all times for operation giving limited opportunity for maintenance activity.

- Spares are on a long lead time for the machines, meaning any unplanned outage with a spares requirement is a large production risk for the end user.

The challenge:

- Repairing and delivering the unit as quick as possible.

The Solution

Sulzer identified the spares required for the machine

To offer a solution to the end user, Sulzer identified the spares required for the machine and procured these ahead of the machine coming onshore. Once the machine arrived onshore the expert teams dismantled the unit and recorded the coil specification and had the Sulzer Birmingham state of the art coil winding facility prepared for winding the coils in an express fashion which were complete within 3 weeks while the stator and rotor had remedial works completed.

Work completed on the unit within the 10 week window:

- Machine dismantled and had an Atex inspection carried out with some further defects noted.

- Winding details specified.

- Winding coils manufactured and fitted.

- Remedial work completed to motor flamepaths.

- Motor feet were skimmed with additional shimming purchased to ensure minimal risk of soft foot issues when reinstalled.

- Consumable glands and boots purchased.

- Machine assembled, and completed.

- Motor full load test completed in house.

Customer Benefit

- Works finalized within 10 weeks, 2 weeks ahead of schedule.

- Improved reliability of the machines going forward due to their inherent condition.

- Limited exposure for end user to production risk.

- Motor Lifecycle Improvement.

By meticulous planning and effective project management Sulzer were able to execute a large scope of work in a short time ensuring the end clients production was not affected. Sulzer completed the scope 2 weeks ahead of schedule despite facing additional unplanned defects.

Explore our rotating equipment solutions

Contact our Electromechanical Services team

We're here to help! Get in touch to discuss your requirements with our electromechanical experts.