-

OHH overhung single stage pumpsThe OHH is our API 610 (ISO 13709) type OH2 overhung, horizontal, centerline mounted, single stage, radially split process pump.

-

OHHL low flow high head pumpsThe OHHL is our API 610 (ISO 13709) type OH2 low-flow horizontal overhung process pump. It covers the low-flow end of the OHH range map.

-

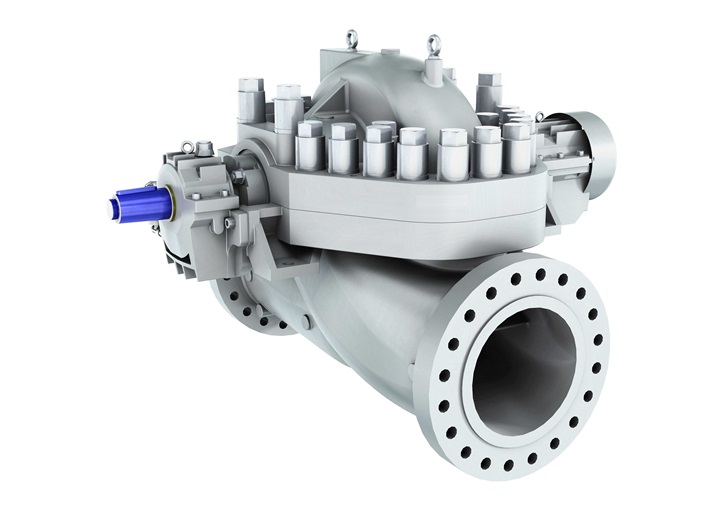

HSB axially split single stage between bearing pumpThe HSB API 610 (ISO 13709) Type BB1 is an axially split, single stage, horizontal, between bearing pump. Many HSB pumps are in service on crude oil pipelines in many parts of the world. Its robust casing and custom hydraulics are specifically designed to meet project requirements.

Alkylation

Complete solutions for difficult process units

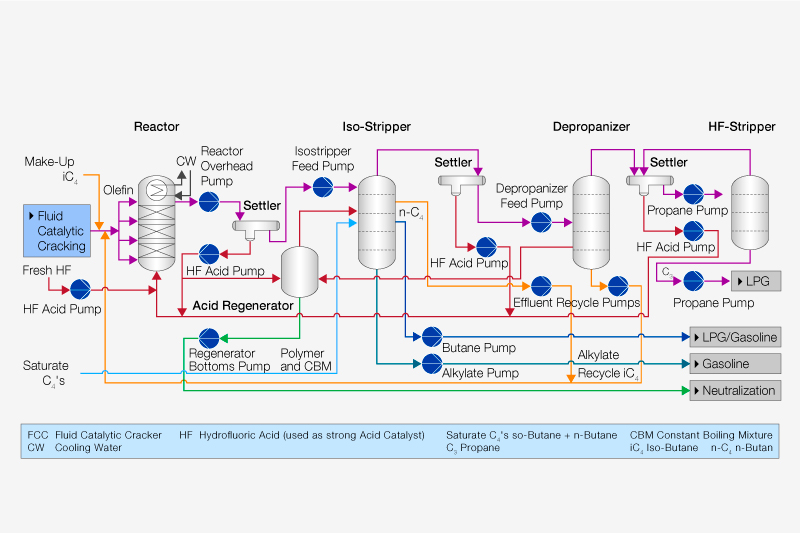

The alkylation process combines C3 - C5 olefins (primarily C4) from the FCC unit with isobutane to produce high quality gasoline. The process occurs in the presence of either HF or H2SO4; this provides additional challenges that need to be considered.

State of the art processing technology and equipment are essential for efficient and reliable operation.

Alkylation process

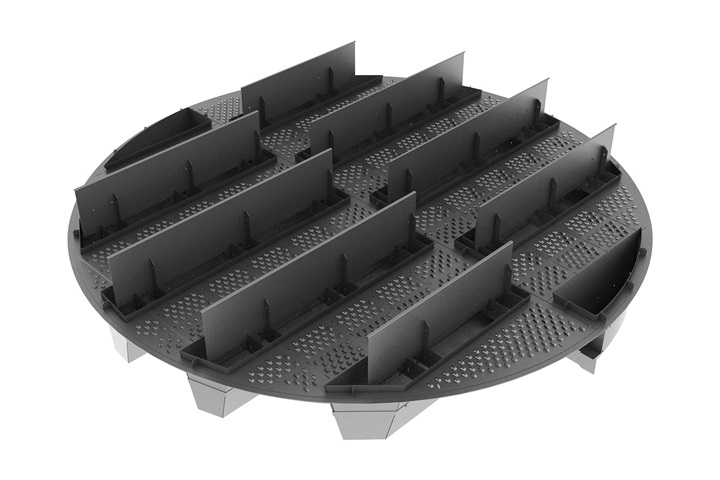

The alkylation unit takes a relatively light olefin stream from the FCC unit and then mixes it with a recycle isobutane stream and an acid catalyst to produce high quality alkylate gasoline. After the reaction and settling stage, the product stream is processed to recover light ends, a large isobutane recycle stream, butane, and the alkylate product. This is done through a series of substantial distillation columns.This process uses Sulzer equipment in the mixers, settlers, pumps, and distillation columns.

These sub-columns are named in a self-explanatory way:

- HF Stripper: HF acid removal/recovery

- Depropanizer: Propane removal/recovery

- Isostripper/Main Fractionator: Isobutane and butanes recovery along with an alkylate bottoms product

- Deisobutanizer: Separates the isobutane overhead and normal butane as a side draw

Alkylate is superior gasoline blending component with low RVP and high octane. This process uses Sulzer equipment in the mixers, settlers, pumps, and distillation columns.