-

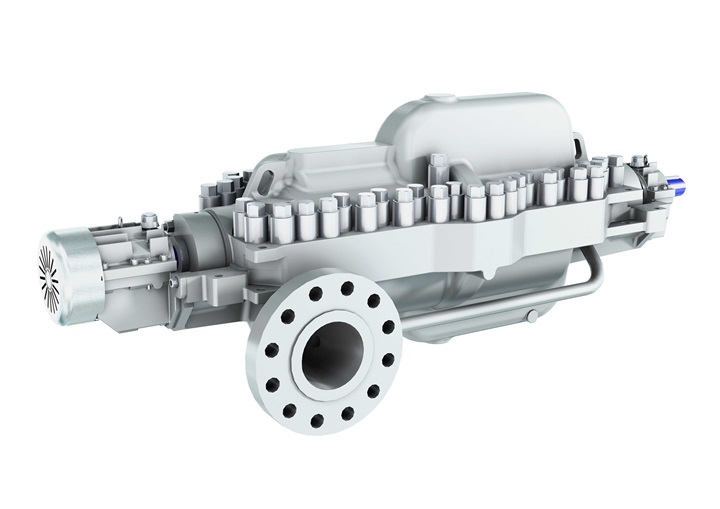

MSD axially split multistage pumpThe MSD pump has the broadest hydraulic coverage of any BB3 type multistage pump in the market. There are over 10 000 MSD pumps installed in product pipelines, boiler feed, water injection and even nuclear safety-related services around the globe.

-

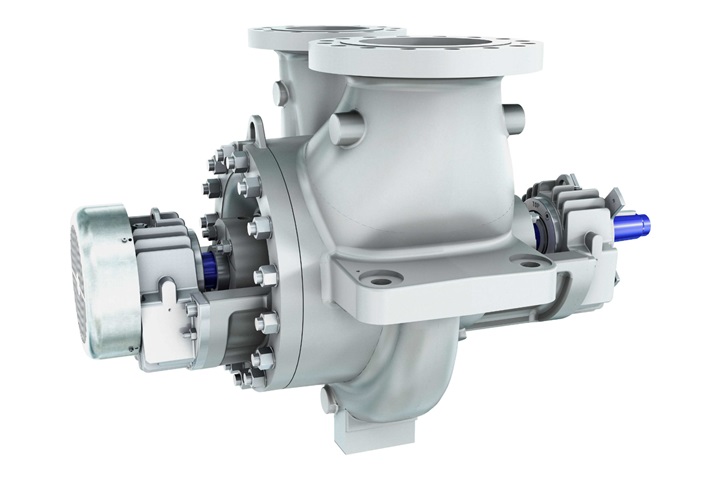

BBS and CD between bearings single stage pumpsThe BBS and CD models are API 610 (ISO 13709) type BB2, single stage, radially split pumps. They offer the widest range of hydraulic performance in the industry.

-

OHH overhung single stage pumpsThe OHH is our API 610 (ISO 13709) type OH2 overhung, horizontal, centerline mounted, single stage, radially split process pump.

-

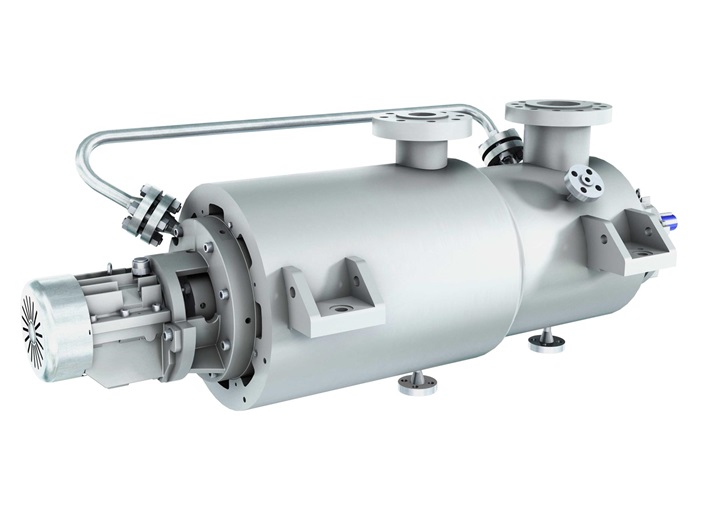

CP volute style barrel pumpCP ISO 13709 / API 610 Type BB5 radially split barrel casing pumps are used in both high-pressure oil production and high-temperature refinery applications.

-

GSG diffuser style barrel pumpThe GSG pump is the least costly form of ISO 13709 / API 610 Type BB5 high-pressure barrel pumps. The GSG back-to-back rotor stack is supplied on low- density services where rotor stability is critical.

Hydrotreating Unit

Maximize Hydrotreater performance with our technology

We are very experienced in hydrotreater technology. We provide everything from process licensing with our MaxFlux and BioFlux processes as well as column and separator internals and API 610 process pumps for any process configuration.

Whether you have a grass roots or revamp application, our experienced engineers will provide you with the best possible, most cost-effective, and robust solution to meet your individual requirements.

Hydrotreating process

Hydrotreating is used for a variety of hydrocarbon streams ranging from naphtha to vacuum tower residue. The emphasis is typically on the removal of contaminants such as sulfur and nitrogen to avoid poisoning downstream catalysts.

In the hydrotreating process, the feed stream is pressurized, heated, and combined with hydrogen and then fed to a reactor. In the reactor, the hydrogen reacts with sulfur and nitrogen bearing species and forms H2S and/or NH3. These compounds are then removed in the stripper column. The stripped reactor effluent is then sent for downstream processing to make high value products. Sulzer licenses several hydrotreating processes for treating pygas, naphtha, distillates, and heavy oils.

One of the main advantages of the Sulzer GTC hydrotreaters processes is the elimination of the recycle hydrogen loop. The main process vessels are the reactors, separators, strippers and a distillation column. These applications are often at higher pressures and trays are the column internal of choice. High pressure API-610 pumps are typical.