- High-efficiency IE3 motor for reliable operation

- High wear resistance ensures years of cost-efficient pumping

- Flexible design makes it easy to convert the pump for different hydraulic requirements

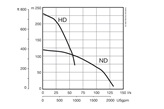

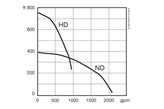

Submersible drainage pump XJ 900

High-head drainage pump with high-flow capability

- XJ 900 HD high head 3-phase

- XJ 900 ND high flow 3-phase

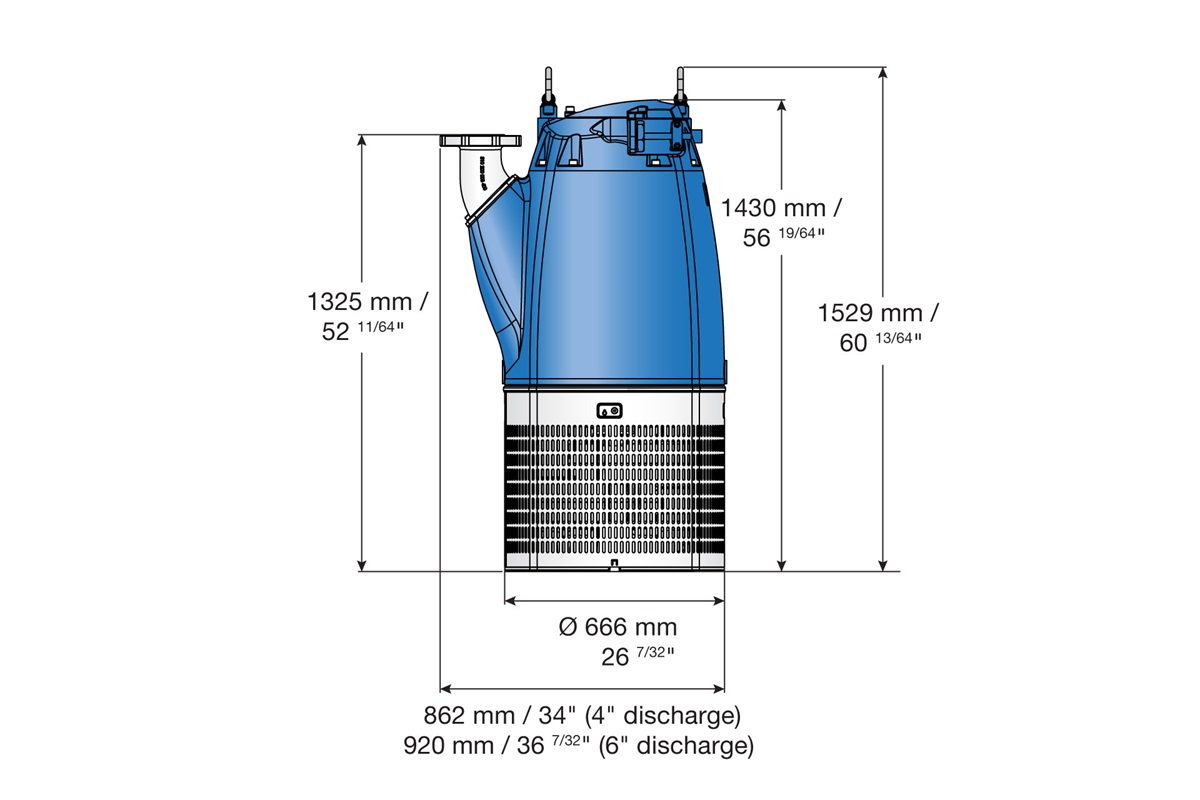

Weight: 1'200 kg (2'646 lb.)

Motor protection

- Thermal control system with temperature sensors in the motor windings for automatic shut-down in case of overheating

- Seal monitoring system with leakage sensor in the junction box and motor chamber for automatic shut-down if water has entered the pump

- Leakage sensor in the oil chamber indicating presence of water in the oil

- Optional bearing monitoring system with temperature sensors at upper and lower bearing indicating excessive temperature

Discharge connections

DN 100/4” (standard HD)

Flange connection PN40 DIN 1092-1

Flange connection class 250 ASME B16.1 1998

DN150 / 6” (standard ND)

Flange connection PN40 DIN1092-1

Flange connection class 150 ASME B16.5 1998

Reliable operation

Strong cast iron construction with outer casing gives good cooling and enables the pump to run at operating water levels all the way down to the strainer.

Wear resistance

One investment for years of cost-efficient pumping. Impellers built back to back together with double exit volutes, and flow elbows in white cast iron ensure a long lifetime and high efficiency.

Flexible hydraulics

For easy conversion from ND to HD the pump is fitted with impellers and diffusers for both HD and ND versions. This give the option to stock fewer pumps and still have the right hydraulic performance for the job.

| Electric submersible pump | XJ 900 |

| Maximum submergence | 80 m |

| Protection class | IP68 |

| Max. temperature of pumped medium at max. power input and continuous duty | 40 °C |

| Max. media density | 1'100 kg/m3 |

| pH of the pumped medium | 5-8 |

| Strainer hole | 8 x 34 mm |

| Max. number of starts | 15/hr |

| Motor rating P2 | 90 kW |

| Speed | 2'970 rpm |

| Power cable | 20 m type NSSHOEU |

| Electric submersible pump | XJ 900 |

| Maximum submergence | 80 m |

| Protection class | IP68 |

| Max. temperature of pumped medium at max. power input and continuous duty | 40 °C |

| Max. media density | 1'100 kg/m3 |

| pH of the pumped medium | 5-8 |

| Strainer hole | 8 x 34 mm |

| Max. number of starts | 15/hr |

| Motor rating P2 | 108 kW |

| Speed | 3'560 rpm |

| Power cable | 20 m type NSSHOEU |

| Electric submersible pump | XJ 900 |

| Maximum submergence | 262 ft. |

| Protection class | IP68 |

Max. temperature of pumped medium at max. power input and continuous duty |

104 °F |

| Max. media density | 0.0397 lbs/inch3 |

| pH of the pumped medium | 5-8 |

| Strainer hole | 5/16” x 1 5/16” |

| Max. number of starts | 15/hr |

| Motor rating P2 | 145 Hp |

| Speed | 3'560 rpm |

| Power cable | 100 ft type W |