Maintenance and repairs

Reduce losses in efficiency

For the full restoration of your critical high-speed steam turbines, contact Sulzer. We offer basic and advanced repair and overhaul services, as well as component remanufacturing for both power and industrial steam turbines.

Sulzer provides exceptional project management services for your outages and repairs, ensuring the entire job is completed on time. When process conditions change, we can rerate and upgrade your machinery. Failure analysis and in-house metallurgy help restore top condition of your steam turbine. You can rely on our fast and flexible services.

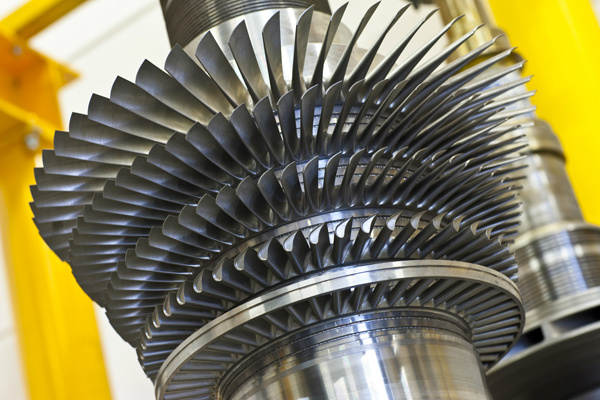

Our Steam Turbine maintenance and overhaul capabilities

OEM: More than 50

Models: More than 450

Power capacity:1-600MW (1300-134,000 HP)

Speed: 3600 to 7200 RPM

Weight: More than 100 Tonnes

Non-exhaustive standard repair processes include:

- Blade removal and reinstallation/ reblading

- Stellite shield replacement

- Diaphragm repair and replacement

- Guide blade carrier repair

- Impeller stacking

- Guide blade carrier repair and modifications

- Cold and hot peening of tenons

- Machining (both turning and milling)

- Grinding

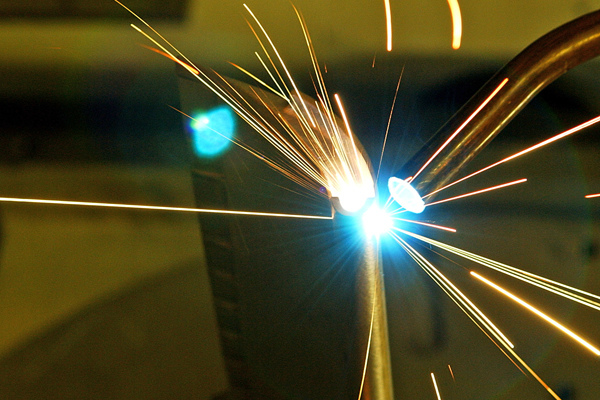

- Welding disks and shaft areas such as bearing journals, coupling fits, steam seal areas, interstage seal areas, etc.

- Complete disk rebuilds on integral rotors

- Manufacturing of blades, diaphragms, shafts, integral rotors, sleeves, and all other turbine components

- Coating

- In-shop turbine disassembly/assembly

- Low-speed balancing

- At-speed balancing

- Field installation and start-up assistance

- Advanced rotor restoration welding

We offer full machine shop capabilities, including:

- Computer Numerical Control (CNC) and conventional horizontal and vertical lathes

- Both horizontal and vertical boring mills