-

Submersible mixed flow column pump type ABS AFLXSave space and reduce installation costs with the AFLX range of submersible axial-flow pumps, designed for direct installation in discharge pipes.

-

AHLSTAR A process pump rangeAHLSTAR A end-suction single-stage centrifugal process pumps are used for demanding industrial applications to ensure process reliability, high efficiency and low operating costs. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR EPP/T high-temperature process pump rangeAHLSTAR EPP/T centerline supported end-suction single-stage centrifugal process pumps are designed to stand high temperature especially in demanding industrial hot liquid pumping applications. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR NPP/T non-clogging process pump rangeAHLSTAR NPP/T non-clogging end-suction single-stage centrifugal process pumps are designed for industrial large solids containing liquid or abrasive slurry applications to avoid plugging. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR WPP/T wear-resistant process pump rangeAHLSTAR WPP/T wear-resistant end-suction single-stage centrifugal pumps are designed for abrasive and erosive pumping applications, such as lime milk and mud, and coating pigments. The pump exceeds the requirements of ISO 5199.

Case study

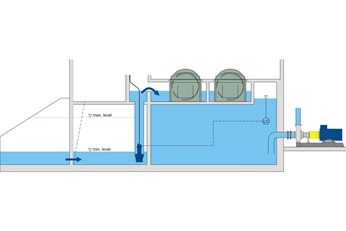

Efficient submersible pumps for pulp mill water intake

SCA Packaging Munksund, a pulp mill located on the northern coast of Sweden, needed to replace its water intake station, which was built as early as 1928. A new pumping station was built in 2009. Four submersible pumps with high flow and low head were required to lift river water up to disc filters, thereafter being distributed by four AHLSTAR end suctions pumps.

The challenge

When selecting the supplier, an important condition set by SCA Packaging was understanding the customer requirements:

- Knowledge of the demands of the pulp and paper industry, including local Swedish branch standards SSG

- Thorough know-how in pumping station design and operation

- Reliable management of seasonal variations in water quality and flow

- Energy-efficient pumps

The solution

- Supply of four reliable submersible mixed flow column pumps type ABS AFLX, including raiser pipe

- All hydraulic parts and raiser pipe in stainless steel, due to seasonal variations in water quality – pH and humus

- Support for control strategy with variable frequency drives and for how to switch operation between pumps

- Professional assistance in pump sump design

- Trouble-free start-up with Sulzer installation supervision

Leif Risberg - SCA Packaging

With Sulzer we could be sure to have a reliable supplier who knows the pulp and paper industry and delivers efficient submersible pumps.

Customer benefit

As a well-known supplier in the pulp and paper industry, Sulzer understands and is able to fulfill local requirements and standards. The installed pumps were supplied with an option for future upgrades. Today there is a service agreement in place for regular condition monitoring of the pumps, performed by experienced Sulzer service staff. The Sulzer pumps have been operating smoothly and efficiently ever since the start-up.

Key characteristics

| Flow | 1’180 m3/h |

| Head | 4.95 m |

| Hydraulic parts | stainless steel (impeller, shaft, bellmouth, diffusor etc.) |

| Raiser pipe | stainless steel, length 4’500 mm |