- Copper smelters

- Floatation, thickening and tailings transportation

- Various stages of leaching

- Electrorefining of copper anodes

- Electrolyte purification and anode slime treatment

- Gas scrubbing

- Water transport, boiler feed, mine dewatering, high head mine dewatering

Copper applications

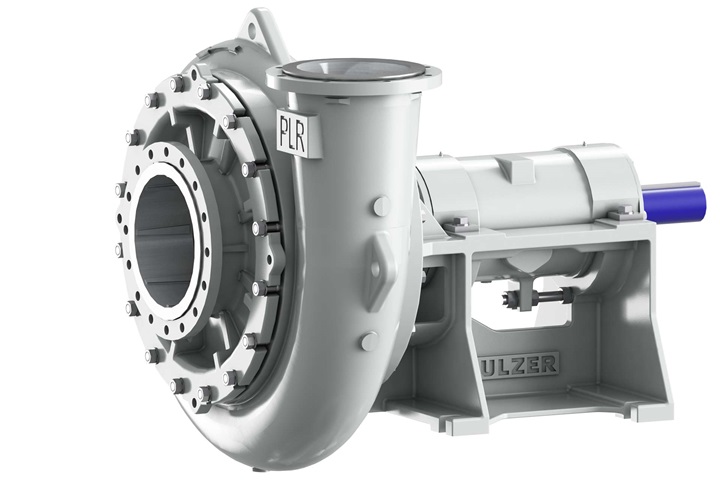

Maximize efficiency and durability in copper applications, while reducing energy costs and water consumption. With an advanced selection of materials for a comprehensive portfolio, Sulzer ensures reliable performance at minimized downtime, even in demanding environments.

- Maximized efficiency

- Reliability and durability

- Reduced energy costs

- Reduced water consumption

- Fit for demanding environments

Find robust, corrosion- and wear-resistant process equipment tailored for the demanding environments of both hydrometallurgical and pyrometallurgical copper processing. Engineered to handle aggressive slurries containing chlorides, fluorides, and acids, Sulzer‘s pumps and agitators feature specialized materials and modular designs that minimize abrasion, corrosion, and unplanned downtime.

With scalable capacity and comprehensive wear-part options, our solutions help you reach enhanced uptime, productivity, and cost-efficiency. Additionally to process equipment, our offering covers advanced water treatment systems designed for zero discharge as well as lifecycle services.