-

API 610 and ISO 13709 pumpsAPI 610 / ISO 13709 international standard specifies requirements for overhung, between-bearings and vertically-suspended centrifugal pumps used in petroleum, petrochemical and gas industry process services.

-

CPE ANSI process pumps range (ANSI/ASME B73.1)CPE ANSI pumps are specifically designed to exceed the strictest energy regulations for all industries as well as the requirements of ASME B73.1. With revolutionary hydraulics and high efficiency, they offer the lowest life cycle costs.

-

OHH overhung single stage pumpsThe OHH is our API 610 (ISO 13709) type OH2 overhung, horizontal, centerline mounted, single stage, radially split process pump.

-

OHHL low flow high head pumpsThe OHHL is our API 610 (ISO 13709) type OH2 low-flow horizontal overhung process pump. It covers the low-flow end of the OHH range map.

-

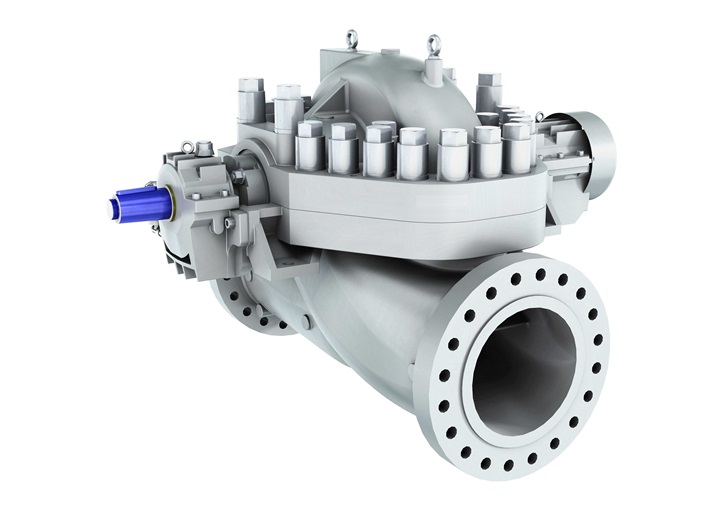

HSB axially split single stage between bearing pumpThe HSB API 610 (ISO 13709) Type BB1 is an axially split, single stage, horizontal, between bearing pump. Many HSB pumps are in service on crude oil pipelines in many parts of the world. Its robust casing and custom hydraulics are specifically designed to meet project requirements.

-

PRE end suction pump rangeThe PRE is our API 610 (ISO 13709) Type OH2 overhung, horizontal, centerline mounted, single stage, radially split process pump. The highly configurable design offers reliability, high efficiency and minimum pump life cycle cost.

Crude oil desalting

Reliable solutions for critical services

Crude oil desalting process

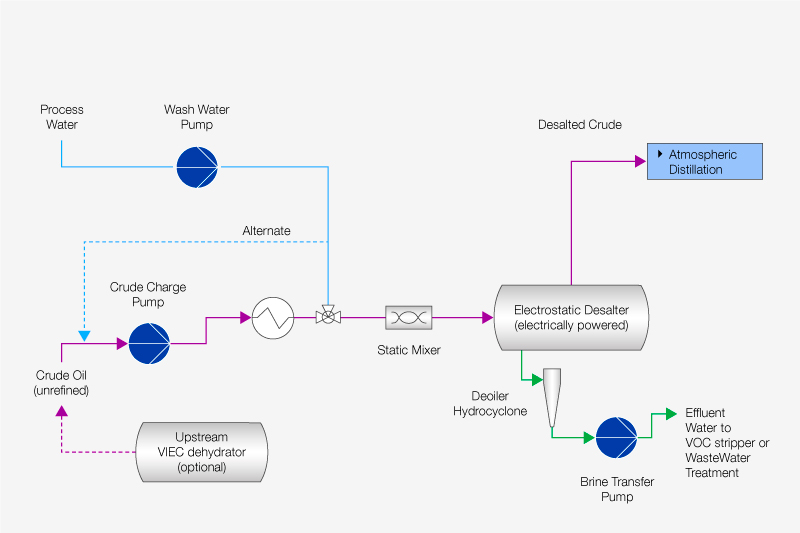

Refinery desalting is typically done in one or two stages. This is determined by the characteristics and expected level of contamination after any pre-treatment done at the well head or pre-transportation stage.

The desalting process consists of mixing heated crude oil with wash water and emulsion breaking chemicals. Proper mixing is critical to the salt removal and is achieved using mixing valves and static mixers. The emulsion is broken by a high voltage electrostatic field within the gravity settler tank. The brine water phase containing extracted salts and other impurities is removed from the bottom for treatment. The desalted crude oil is then transferred to the atmospheric distillation column.

The brine fluid produced is extremely corrosive and requires special materials of construction to avoid possible desalter shutdown and risk of plant shutdown. Austenitic stainless steel or Duplex materials are commonly specified.

Desalting can start earlier in the process train at higher water cuts with gas present. Our VIEC separation technology achieves low water contents in the oil stream, which reduces the number of downstream desalters required as well as water consumption.