- Simple and robust design with ease of maintenance

- High reliability

- Minimum life cycle costs

- Wide range of different hydraulic options

- Can run dry

- No sealing system required

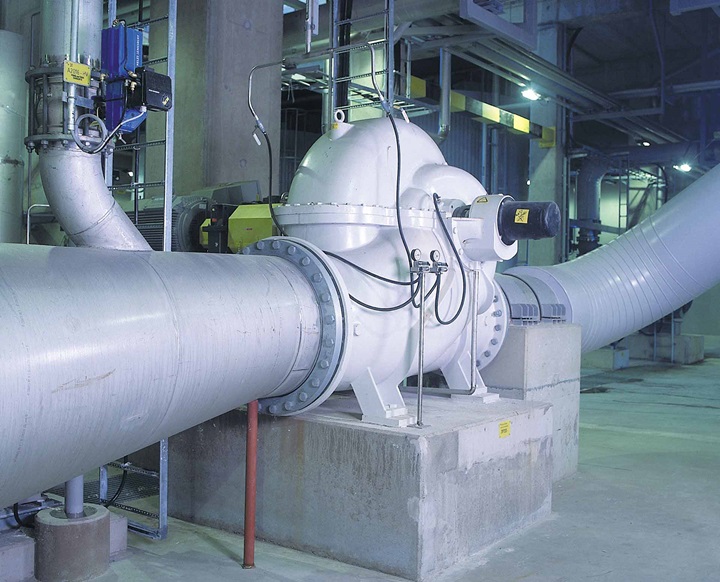

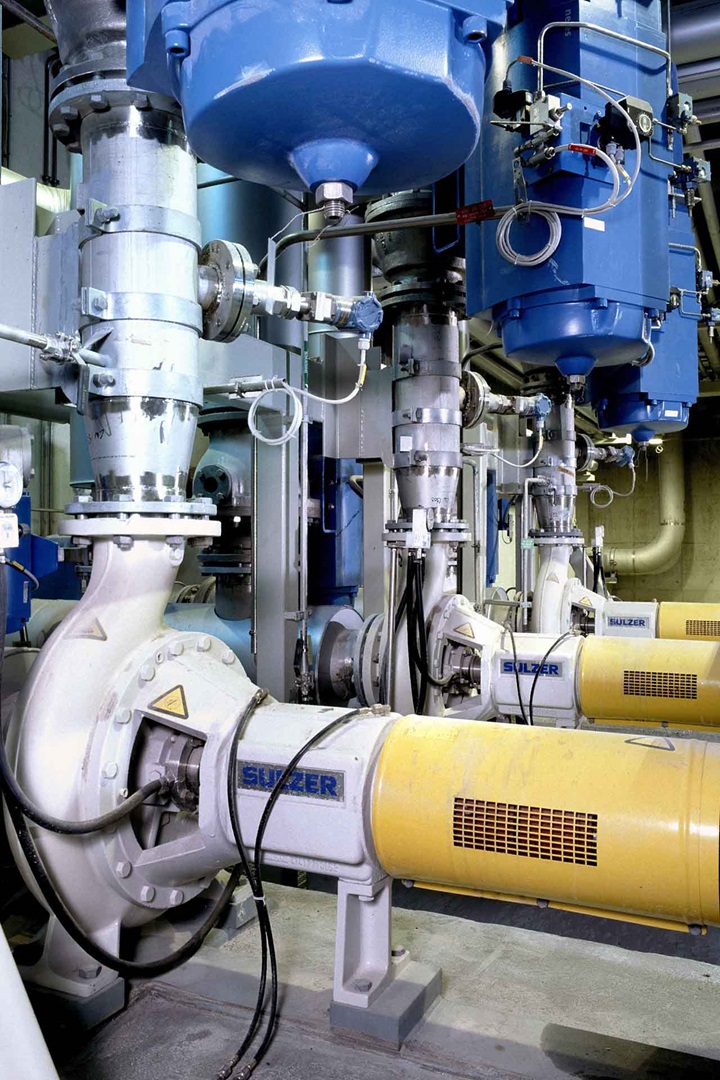

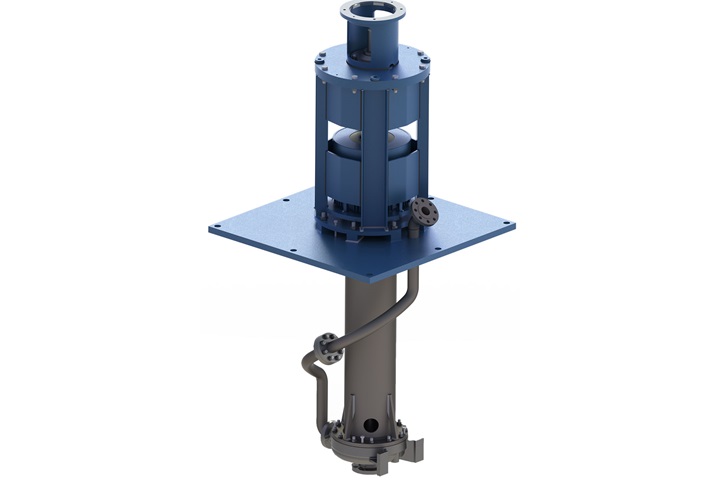

VA cantilever sump pump

Cantilever sump pump for demanding applications

The VA cantilever sump pump range has been designed for pumping all kinds of clean and contaminated liquids and slurry. Due to its great adaptability through a wide range of designs and hydraulics, the VA vertical pump is perfectly suitable for a wide range of industrial applications.

The VA cantilever sump pump is perfectly suitable for all industrial sump pump applications:

- Industrial water

- Effluents

- Corrosive and abrasive mixtures

- Hazardous fluids

- Abrasive liquids and/or liquids containing large solids

- Abrasive fibrous slurries and/or fibrous slurries containing large solids

- Abrasive non-fibrous slurries and/or non-fibrous slurries containing large solids

- Heavy slurry

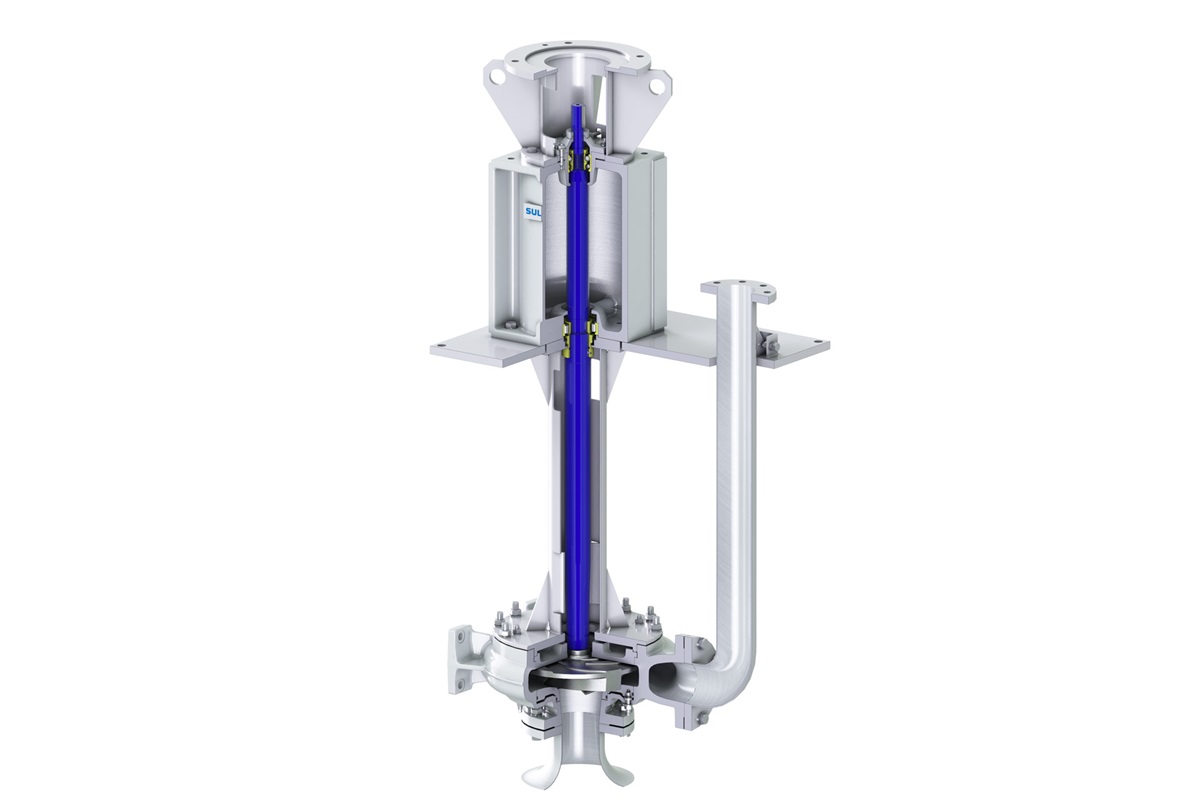

Main design features

- Wide range of different hydraulic options: semi-open, open, closed or vortex impellers

- No sealing required

- No intermediate bearing

- Dry running allowed for selected hydraulics

- Discharge separate from the shaft line

- Bearing assembly is sealed to prevent contamination by liquids or gases

Key characteristics

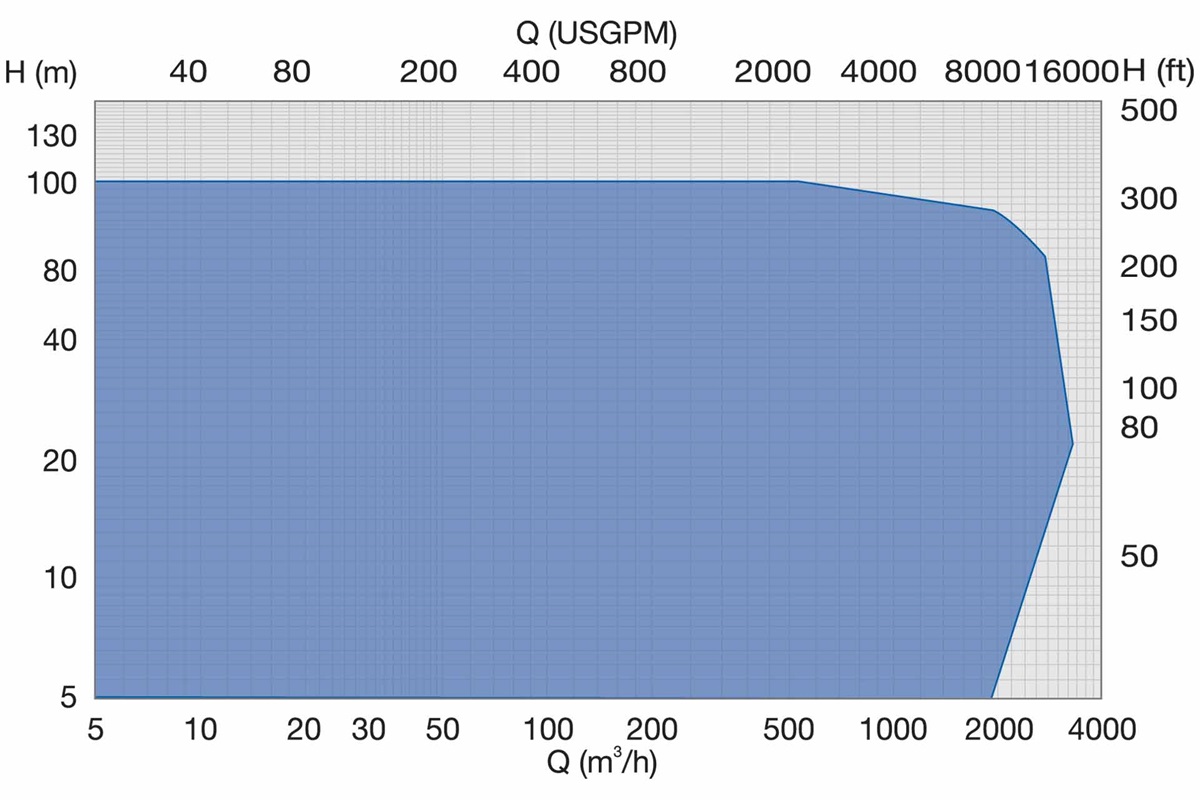

| Capacities | up to 3’500 m3/h / 15’500 USgpm |

| Heads | 100 m / 330 ft |

| Pressures | up to 20 bar / 290 psi |

| Temperatures | up to 120°C / 250°F |

| Speed | up to 3’000 rpm |

Documents

Brochures

Case studies, articles and news

-

Sulzer launches extended VA vertical cantilever sump pump rangeDecember 09, 2021Sulzer launches an upgrade of the VA vertical cantilever sump pump. The VA pump range has been designed for pumping all kinds of clean and contaminated liquids and slurry. Thanks to its great adaptability through a wide range of designs and hydraulics, the VA pump is perfectly suitable for all industrial applications.

-

Driving up efficiencyThe adoption of electric vehicles across the world is increasing rapidly and this demand needs to be matched by the supply of batteries. As new processing plants and manufacturing facilities are constructed, it is important that they employ the latest in pumping technology to ensure optimum reliability and efficiency. Read the article.

-

Pumping equipment in phosphate fertilizer processesPumps are at the heart of phosphate fertilizer production, and correct equipment selection that takes into consideration hydraulic design, materials of construction, application knowledge, duty point and maintenance regime are critical to achieving reliable long-term pumping operation and maximum plant production. Read the whole article.

-

Case studiesWherever fluids are pumped, mixed, controlled or applied, we are there. See how our solutions create value for customers and learn how we can make your pumping and mixing processes more efficient and profitable, safeguarding your production and ensuring lasting reliability.

Industries

-

Paper and board machine and systemsSulzer’s extensive product portfolio is designed to meet the most demanding hydraulic coverage requirements and for all types of liquids, making it ideal for challenging pumping, agitation, and mixing operations in stock preparation, PM approach system, broke system, white water system, vacuum system, condensate system, and shower water system processes.

-

Chemicals for Pulp Paper and BoardTailored designs, features and material selections to meet the most demanding pumping, mixing, and agitation challenges in the production and preparation of chemicals, tall oil production, and lignin processing.

-

FertilizersOur pumps, mixers and agitators provide durability and reliability for fertilizers production as well as for corrosive and abrasive liquids and high gas content. Our specific industry experience also includes separation processes and servicing of pumps, compressors, turbines, and motors.

-

MiningWhether on the surface or underground, the conditions in mines are harsh. Besides the mud, slurry, stones, and rocks, there are large volumes of water to remove in order to keep production moving. Our dewatering pumps are rugged and ready, taking on the toughest drainage and sludge removal.

-

MetalsSulzer’s pumping and mixing solutions for the metal industry are designed for corrosive and abrasive liquids. We offer expertise e.g. for the production of aluminum, copper, nickel, zinc, and precious metals.

-

ChemicalsSulzer improves quality, capacity, and energy efficiency with its advanced technologies and services for separation processes; including distillation, absorption, evaporation, extraction and crystallization. Our pumps, mixers, and agitators cover the specific requirements in chemical processes.

-

Chemical recoverySulzer’s extensive product portfolio is designed to meet the most demanding hydraulic coverage requirements in your evaporation, recovery boiler, and white liquor preparation processes.

-

Water intake, transportation and irrigationSulzer offers various reliable pumping solutions for water intake, water transportation, industrial water supply, distribution and irrigation.

-

Industrial water and effluent treatmentSulzer has a deep knowledge in wastewater treatment, and with our wide product portfolio we can now offer energy-efficient and reliable solutions for your water collection, neutralization, flocculation, sedimentation, cooling, aeration, sludge storage, digestion, and dewatering processes.

-

Sugar, starch and sweetenersEfficient production of sugar, starch and sweeteners puts high demands on the processing equipment. Thanks to many years of experience and comprehensive process know-how, Sulzer offers a wide portfolio of innovative process pumps, special pumps, mixers, agitators, compressors and aerators for these industry sectors.

-

BiofuelsBiofuels from renewable sources show great potential as sustainable transportation fuel. Based on our experience in demanding processes, we work with customers to develop advanced pumping, mixing, and distillation solutions for the production of biofuels, from pilot to commercial-scale installations.

Related products

-

VM vertically suspended sump pumpThe design of the VM vertically suspended sump pump includes a wide range of hydraulics. This makes it perfect for several industrial applications for pumping sump and corrosive liquids and slurries.

-

Heavy-duty cantilever sump pump type Ensival Moret VAPThe VAP vertical cantilever sump pump is especially suited for heavy-duty applications. The wide range of designs, hydraulics and materials makes it adaptable for all types of severe applications.

-

AHLSTAR A process pump rangeAHLSTAR A end-suction single-stage centrifugal process pumps are used for demanding industrial applications to ensure process reliability, high efficiency and low operating costs. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR NPP/T non-clogging process pump rangeAHLSTAR NPP/T non-clogging end-suction single-stage centrifugal process pumps are designed for industrial large solids containing liquid or abrasive slurry applications to avoid plugging. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR WPP/T wear-resistant process pump rangeAHLSTAR WPP/T wear-resistant end-suction single-stage centrifugal pumps are designed for abrasive and erosive pumping applications, such as lime milk and mud, and coating pigments. The pump exceeds the requirements of ISO 5199.

-

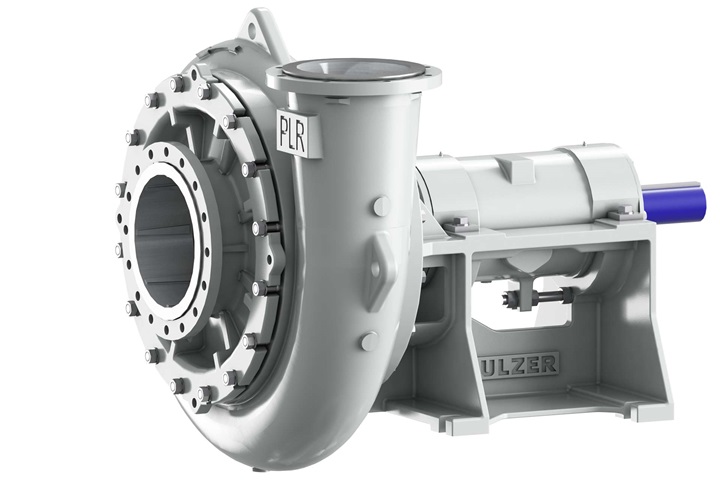

PLR slurry pumpThe PLR range has been specifically designed to handle liquids with a high solids contents. It is designed to be manufactured from special materials with a high hardness level thus affording the best anti-abrasion characteristics.

-

Heavy-duty slurry pumps type Ensival Moret EMWThe EMW pump range has been designed considering historic field experience, coupled with the latest in fluid flow modeling technologies and finite element analysis, to create the latest in slurry pumping technology.

Videos

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

Careful commissioning of the pump plays a key role in the safe and reliable use of the pump

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

Connecting the pipes to the pump correctly is essential for ensuring the reliability of the pump

Talk or write to our experts to find your best solution.