Transforming industry with additive manufacturing

3D printing can offer several manufacturing advantages

Exploring different AM processes

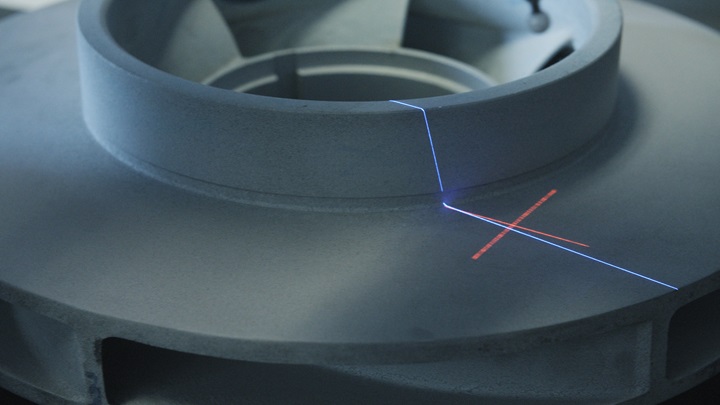

Laser powder bed fusion (LPBF), also known as selective laser melting (SLM), is used in the manufacture of spare parts, predominantly in gas turbines and pump parts such as impellers. This technology is especially suitable for working with metallic materials, resulting in high integrity, high strength and durable parts for corrosive and high temperature environments. LPBF provides exceptional geometric freedom, enabling the precise production of complex parts required for high-speed turbomachinery in a toolless manner.

Laser metal deposition (LMD), or directed energy deposition (DED), can use wire or powder as feedstock. This versatile technology is used by Sulzer in several applications for creating remanufactured parts as well as for component repairs.

Sulzer has also pioneered a hybrid technology that combines LMD with machining processes in the same piece of equipment. This enables complex closed impeller geometries to be created quickly with great precision. Due to the higher manufacturing costs, these are predominantly used in the oil & gas and nuclear market.

The impellers created using hybrid manufacturing are more sustainable because their improved hydraulic performance can make them up to 3% more efficient than conventional alternatives. Over the lifetime of a pump, which could be in excess of 20 years, this improvement can deliver significant energy savings for the operator.

Increasing applications with new materials

One of the challenges to the use of AM is working in accordance with the list of materials that have been qualified and approved in industrial settings. These processes that use wire or powdered feedstock are continuously evolving to include new materials, and Sulzer is continuously looking at testing the boundaries and working to expand the range of materials that can be used. For example, AM vanes made using IN738LC, a material complex by design, can withstand extreme temperatures in a gas turbine. As this process advances, the number of applications that can benefit from AM is increasing each year, and that trend is set to continue.

Using new materials to create parts that are better than the originals will most often improve reliability as well as efficiency, reducing energy costs and the carbon footprint of the business. Moreover, these parts can extend the periods between overhauls, further reducing the cost of ownership.

In addition to metals and ceramics, 3D printing of polymers is also being used to create patterns for casting new parts. This significantly speeds up the manufacturing process and enables changes to be made quickly if necessary. Polymers are also used in prototyping new components and 3D printing is hastening this process and reducing lead times.

Faster manufacturing and improved flexibility

The toolless nature of AM is enabling parts to be produced closer to where they are required. The knowledge and expertise required to create the design can be remote from the location making the new parts, improving sustainability as well as reducing lead times.

However, a significant challenge to rapid parts supply is the efficiency of global logistics, which has been highlighted by a number of incidents recently, so the ability to quickly move the manufacturing source for a component can have several benefits. Additive manufacturing offers greater supply chain flexibility, which again optimizes the on time delivery of new parts to the end user.

Pushing standards for wider acceptance

As a relatively new technology, standards and regulations are still catching up with the pace of the rapidly evolving AM landscape, which is holding back implementation in some areas. Having said that, Sulzer has deployed AM to create a pump impeller for the nuclear industry, one of the most heavily regulated industries in the market. As more sectors appreciate the benefits of AM, the associated regulations will be updated to cover these processes.

This will be boosted further as more data becomes available for the long-term performance of parts in the field. While the uptake of AM technology is very positive, there are some markets that are skeptical, and this will only be overcome as more evidence is delivered to support the adoption of this technology.

To that end, there will continue to be a need for collaboration between the technology pioneers and prospective end users who will drive the demand. AM is a complimentary technology that will always offer advantages to industry, especially for repairs and retrofits. As more end users look to benefit from developing technologies, so the number of applications will increase and the costs will reduce.

Contact us

.jpg?mw=346&hash=84E0F85F689038E67B00C21030DA917C)