- Designed to meet both the challenging pumping requirements of molten Sulfur while maintaining full compliance to API 610 specification and design principles to maintain aligned rotating equipment standards within the plant.

- Exceeds operating and mechanical limitations of ANSI designs offered by most competitors

- S-6, A-8, D-1 and D-2 materials as standard (other materials on request)

OCVSF molten sulfur pump

Robust API 610 pump for molten sulfur service

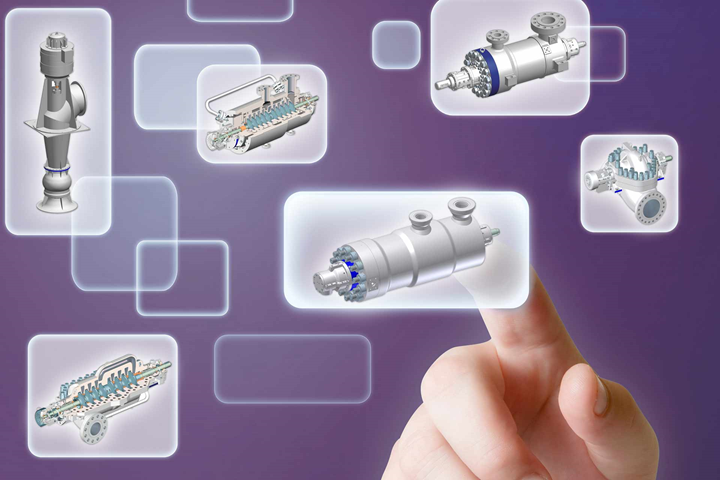

The OCV range of pumps are utilized in refining, oil and gas production, petrochemical, and other heavy duty applications.

- Drainage sumps

- Oily water sumps

- Lube oil supply

- Tank transfer

- Molten sulfur

API 610 pump casing and impeller

• API 610 casing with bypass (spill back) option for minimum continuous flow protection

• Special open impeller with free draining features for handing molten sulfur

• Key driven impeller according API 610 to avoid loose impeller during reverse flow

• Stainless steel suction strainer to help prevent excessive solids entering impeller

Heating jacket

• Column and discharge pipe fully jacketed to maintain sulfur in molten state

• Buttwelded and hydrotested discharge pipe capable of 3X API 610 nozzle loads

Conservative shaft and bearing design

• Bearing spacing follows API 610 to assure that first critical speed of shaft system is well above operating speed

• Heavy duty, high torque shaft may be single piece, or coupled with stud and keyed shaft coupling for ease of maintenance

• Oil lubricated 7300 series thrust bearings with machined brass cages as required by API 610

Column bearings and lubrication

• Iron graphalloy shaft bearings lubricated by filtered product

• Hard coated journal option

• Replaceable bearing spiders

Sealing options

• Single or dual API 682 mechanical seal at mounting plate with API 610 seal chamber

• Gas seals available with plan 72/74 support systems

Mounting plate

• Rectangular epoxy coated carbon steel mounting plate is standard, round mounting plate is optional

• Four point lift allows vertically installation and compensates for pump center of gravity being off center

• Additional rigid coupling option for inspection or replacement of mechanical seal without removal of thrust bearing

Instrumentation

Drivers and couplings

• API 610 non-lubricated couplings are standard, others are optional

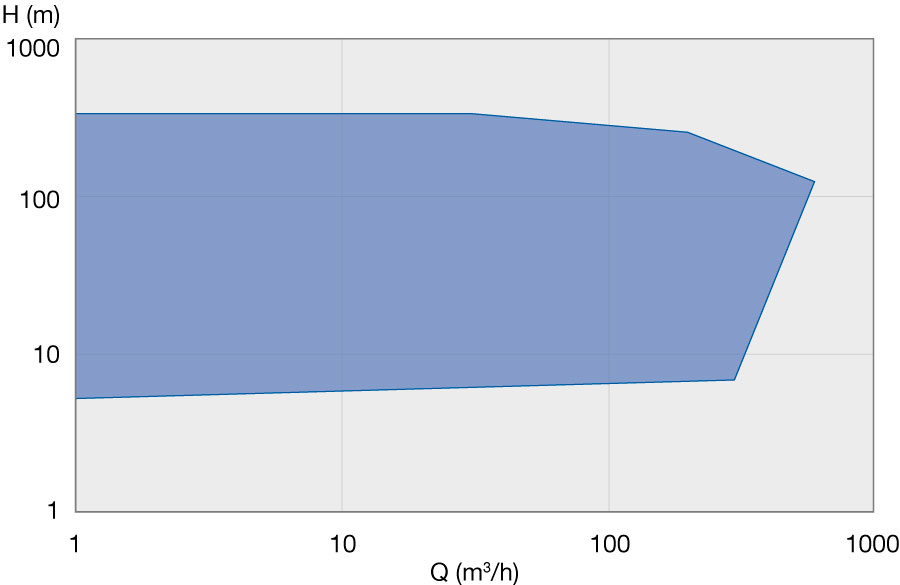

| Pump size | Up to 50 to 100 mm/ 2 to 4 in. |

| Capacities | Up to 200 m3/h / 880 US gpm |

| Heads | Up to 100 m / 330 ft |

| Pressures | Up to 40 bar / 580 psi |

| Temperatures | -46°C to 260°C / -50°F to 500°F |

| Material code | Material |

| S-6 | Carbon steel casing, 12% chrome impeller, lineshaft and wear parts. CS column and discharge pipe, epoxy coated CS mounting plate and driver stand, carbon lineshaft bearings. |

| S-8 | Carbon steel casing, 12% chrome impeller, lineshaft and wear parts. CS column and discharge pipe, epoxy coated CS mounting plate and driver stand, carbon lineshaft bearings. |

| A-8 | 316L SS casing, impeller, shaft, column and discharge pipe. HF 316 SS wear parts. Epoxy coated CS driver stand and mounting plate, carbon lineshaft bearings. |

| D-1 | Duplex SS casing, impeller, lineshaft, column and discharge pipe. Duplex SS vs HF duplex SS wear parts. Epoxy coated CS driver stand and mounting plate, carbon lineshaft bearings. |

| D-2 | Super duplex SS casing, impeller, lineshaft, column and discharge pipe. HF super duplex SS vs super duplex SS wearparts. Epoxy coated CS driver stand and mounting plate, carbon lineshaft bearings. |

| *Additional materials (e.g. alloy 825) on request |