- Longest weir length per given column diameter

- Largest downcomer area (DC) per given column diameter

- Most uniform flow path length

- Most uniform vapor distribution

- Minimum inactive zones

- Maximum bubbling area

Shell high performance trays

Load up: helping you manage high liquid loads

- Refinery: main fractionators' PA and stripping sections

- Olefins: deethanizers, depropanizers, debutanizers, deisobutanizers, superfractionators, C2 and C3 splitters

- Aromatics: xylene splitters, xylene rerun, raffinate columns

- Gas sweetening: absorbers, regenerators

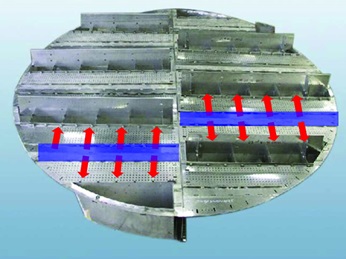

Shell HiFi* Plus trays

Highest capacity at large liquid loadings:

- Lowest pressure drop at large liquid loadings

- Best mass transfer efficiency at large liquid loadings

- Tray spacing as low as 300 mm (11.8 in)

Can be equipped with different types of tray deck:

- MVG™ tray deck

- MMVG™ tray deck

- Other conventional valves like BDH™ floating valves

High reliability:

- Several hundred columns in operation

Mechanical features:

- Multi-downcomers are located offset to the cross section centerline

- Multi-downcomers are supported by a central major beam and 360° tower support ring

- No need for downcomer bolting bars

- Available in boltless lip-slot panel connections that minimize installation time by up to 30%

*) HiFi Plus is a trademark owned and used by the companies of the Shell group.

Shell ConSep* Plus trays

Shell ConSep Plus trays utilize the principle of de-entrainment by centrifugal force to exceed the gravitational limitation of jet flood.

These trays combine the large bubbling area and liquid handling capacity of the contacting Shell HiFi trays and a centrifugal separator in a single stage: Con(tact) and Sep(arator)

Ideal for increasing existing plant capacity (revamps)

- Suitable mainly for 1-to-1 revamping of towers equipped with high performance trays or first generation ConSep trays

- Does not require any welding to the tower wall

- Provides up to 50% more capacity than other high performance trays

Proven technology and excellent reliability based on

- Operating experience in wide variety of columns

- Extensive research and development

- Fractionation Research Inc (FRI) proven

*)ConSep Plus, HiFi are a trademark owned and used by the companies of the Shell group.

Shell CS* Grid trays

The Shell CS* Grid trays are a high-capacity, dual-flow type of tray.

Functional features:

- The contact area for liquid and vapor is achieved by means of adjacent bars

- The open area for liquid and vapor passage is defined by the size and the pitch of the bars

Main applications

The Shell CS Grid trays are mainly used for heat transfer services in fouling applications, and or corrosive environment:

- Slurry pump around of fluid catalytic cracking main fractionator

- Top pump around of crude distillation unit main fractionator and coker main fractionator

- Bottom pump around of thermal cracker main fractionator and visbreaker main fractionator

*) CS Grid is a trademark owned and used by the companies of the Shell group.

Shell HiFi* Extraction trays

- Suitable for systems with interfacial tensions below 25 dyne/cm and large phase ratios

- To enhance capacity of existing extractors

- To increase capacity by up to 25% compared with rotating disc contactors

- To increase capacity by up to 15% compared with conventional extraction trays

- Allow for small tray spacing down to 300 mm

- Can be used among others in aromatic extraction, caustic treating, and lube oil applications

*) HiFi is a trademark owned and used by the companies of the Shell group.

Contact our Separation technology team directly