Explore our solutions

-

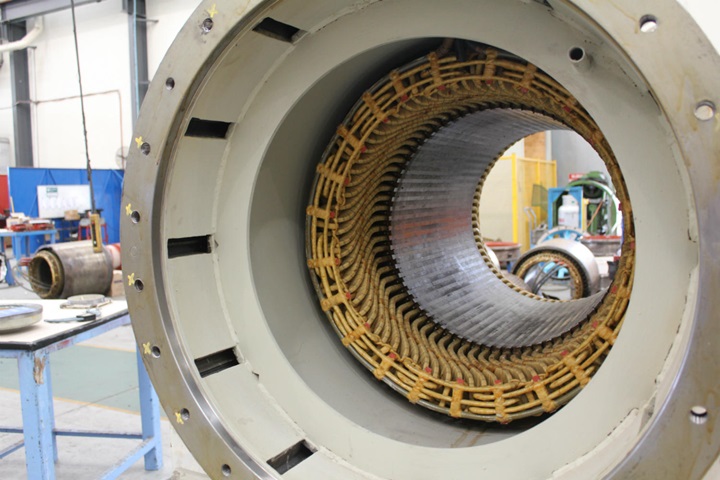

Hazardous area motorsChoose Sulzer for the repair and overhaul of hazardous area motors for the mining industry in compliance with industry standards. We have experience in all aspects of inspection and refurbishment of hazardous area motors.

-

Motors and drivesBased on our expertise in repairing both AC and DC motors, we repair drives, servo motors, and drive systems, thereby saving you money and reducing your energy consumption. We offer repair and preventive maintenance contracts, complete motor and drive system repairs, plus installation and services.