-

Submersible propeller pump type ABS VUPXThe VUPX pumps are ideal for applications where large volumes of storm or process water have to be pumped to heads up to a maximum of 10 meters.

Preventing the city from damage

Efficient storm water protection and ecological balance

The challenge

For flood protection, the new submersible pump arrangement needs to provide the same capacity of 20 cubic meters/s as the existing dry-installed pumps. The Sulzer submersible propeller pumps type VUP are the only ones on the market that fulfill the requirements. During the first construction phase, the physical structure of the building was partly renewed, some of the existing dry-installed pumps were removed and the remaining old pumps secured full flood protection. We were limited to use only three new pumps in this first phase, and with them we have to secure flood protection during the second construction phase. In a second phase, three additional pumps of the same type will be added.

The solution

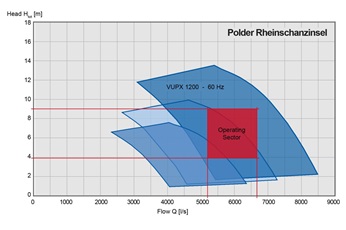

In close cooperation with the consulting engineers and the end customer we came to the conclusion that the required applications and a total capacity of 20 cubic meters/s would be fulfilled with three large Sulzer vertical submersible propeller pumps type ABS VUPX1200. Adjustable propeller blades, a customized special gear box and a 690 V / 60 Hz motor for the German 50 Hz power grid connected to variable frequency drives turned out to be the only solution to meet all requested duty points. A full monitoring system with thermistor sensors, three moisture sensors inside the pump, and shielded cables to ensure electromagnetic compatibility are further unique features of the provided solution.

Barbara Lampert - member of the Regional Council of Karlsruhe

We appreciated the smooth cooperation between the parties during the building phase and are convinced that we can manage future floods with these energy-efficient Sulzer pumps.

Customer benefit

For the end customer:

- Reliable flood protection

- Compact and energy-efficient pump station with submersible pumps

- Better cooling and noise protection due to submerged design

- Long-term reliability

For the consultants/contractors:

- Sulzer’s engineering expertise to prepare multiple complex offers to several contractors during the tendering phase.

- Sulzer VUP reaches all duty points, unlike the corresponding equipment of our main competitors.

- Sulzer fulfilled the requirements of the project more or less without contradictions.

- The feedback provided by different contractors during tendering proves that the Sulzer VUP pumps are the most price competitive pumps on the market for this purpose.

Product data

The order consists of three VUPX1201 M7000/4-95.60 G3.0 and three VUPX1202 M6500/4-95 G3.25. The 700 kW pumps are used for the first construction phase with 6,670 l/s each and approximately 20 cubic meters/s in total, and the 650 kW pumps for the second phase with 5,200 l/s each.

For the second construction phase, the 700 kW pumps will be reduced in flow by variable frequency drives to 5,200 l/s as well. The tender requests a discharge head of 3.92 up to 9.0 meter. Combined with a service contract the end customer was granted a warranty period of five years for the new pumps.