-

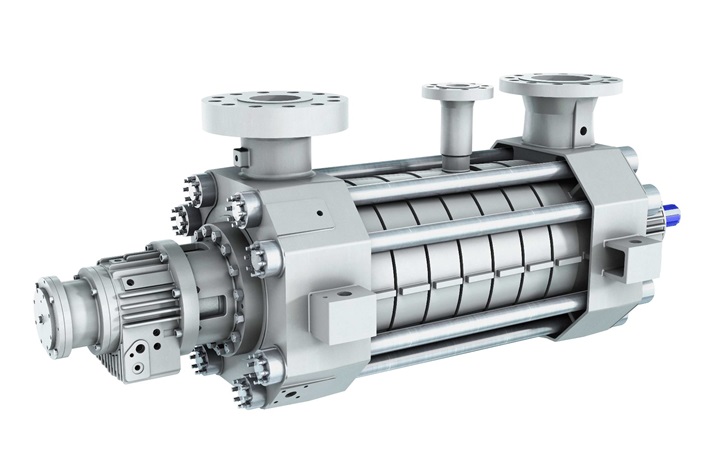

MC high pressure stage casing pumpM-series pumps have a modular design thus allowing Sulzer to find the most efficient solution to meet customer requirements.

-

MD high-pressure stage casing pumpBoth investment costs and lifecycle costs are taken into consideration when designing the optimum possible pump as an optimized hydraulic design guarantees maximum efficiency.

Delivering biofuels to the pump

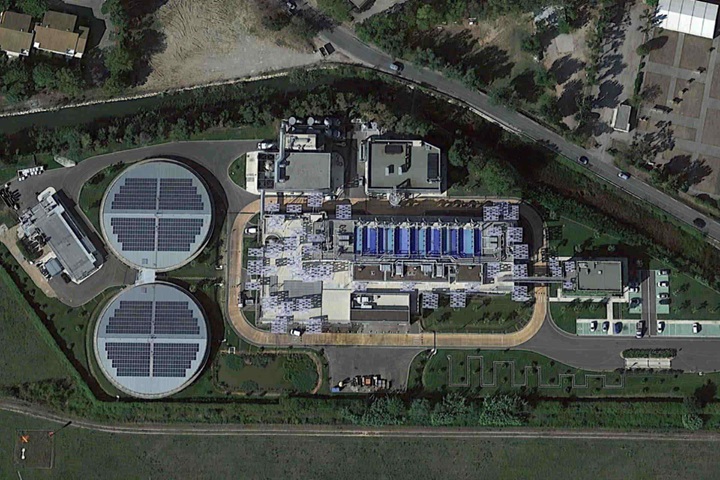

Brazilian ethanol production facility expands with Sulzer pumps

Pumping up capacity

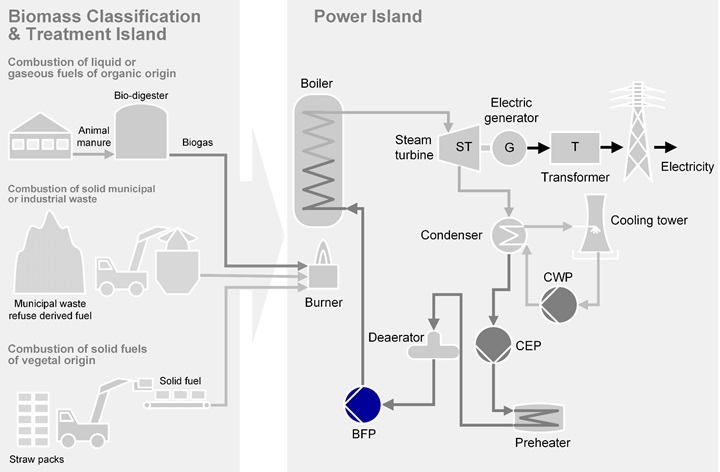

The project required us to provide two pumps to meet two different phases of operation. First, the boiler would operate at 50% power generation capacity, before moving to full power generation in the second phase. The challenge was to specify a pump model that could feed the demineralized water into the boiler across both operating parameters.

Sulzer’s local team of application specialists in Brazil recommended two multi-stage ring section pumps. The pumps are specially designed for boiler feed applications, offering exceptional efficiency thanks to an optimized hydraulic design. Modular hydraulics also allow the pump to meet a wide range of operating conditions. The pump for the first phase will feature a variable frequency drive (VFD) to ensure optimum energy efficiency at 50% capacity, with the second then powered by a turbine, once the boiler is fully operational. This approach ensured that the two operating parameters could be met effectively.

Reliable ethanol production

As sugarcane is grown seasonally, Sulzer can further support customers by carrying out pump inspections and planned preventative maintenance between harvests. Our experience and knowledge as a global pump manufacturer, plus our service center network in Brazil, mean that our customers can benefit from industry-leading pump engineering and maintenance capabilities. This means we can ensure that critical equipment is always in the best possible condition, ready for when ethanol production is at its most intensive. As a result, customers can be sure of maximum pump reliability and performance.

As well as constituting a large portion of Brazil’s energy economy, sugarcane ethanol is a vital fuel for combating climate change. In fact, it has been estimated that if Brazil maximizes its ethanol production capacity, it could reduce current global carbon dioxide emissions by as much as 5.6%. 3

Ancelmo Santana - Sales Specialist of Energy Business at Sulzer Brazil

We are excited to be supporting the production of renewable fuels,our pump technologies can help leading producers deliver low-carbon fuels to Brazil and around the world, reducing carbon emissions.

2 [https://www.sugarcane.org/sugarcane-products/ethanol/]

3 [https://news.illinois.edu/view/6367/570179]