Explore our solutions

-

Rotor repairsOver several decades, Sulzer has developed innovative repair methods for all types of rotating equipment. All these methods have been meticulously tested and qualified to ensure they provide optimal quality while remaining cost-effective.

-

Reverse engineeringRe-engineering provides customers with an alternative for sourcing parts for their equipment. Whether looking to upgrade components, quicker deliveries, or replacing parts, re-engineering provides an opportunity to ensure your equipment keeps running at peak performance.

-

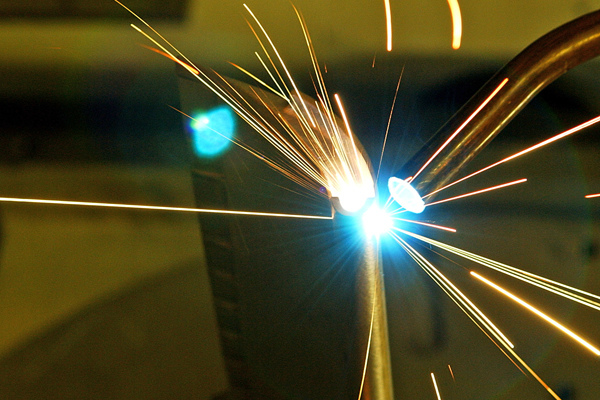

Weld repairsDecreased performance of your gas turbine means lost production. Sulzer has developed many proprietary welding procedures for components. They will restore performance, reduce costs, and increase the lifetime of your machinery.