Solving wastewater challenges

Combining pumps and sewage grinders to solve blockage

The composition of wastewater has changed dramatically in recent years. An increasing number of items, such as personal care wipes, is going into the waste stream. At the same time, there is a clear focus in all countries to reduce water consumption. Less water and more solids and fibrous materials places tough demands on collection networks. In many cases, wastewater pumping stations that worked well just a few years ago are now struggling.

Not only do they have to face the increased risk of blockage, moving towards a sustainable environment also requires reduced energy consumption and high efficiency for all machines and processes.

Choose the right equipment for the job

It is clear that some pumping equipment using optimized hydraulic designs is better at handling solids-laden wastewater streams. As an example, Sulzer’s submersible sewage pumps type ABS XFP with a Premium Efficiency motor and the unique Contrablock Plus impellers offer some of the market’s highest hydraulic efficiencies and feature superior rag handling capacity.

However, when it comes to critical pumping stations, you may require more than just the best pump and impeller. In many cases the consequence of failure is so high that the right business decision is to use both a grinder and the best rag-handling pumps. The same goes for pumping stations with improper design or ones that are already facing the problem of excessive rag content.

How do I know if I need a grinder?

For critical pump stations that require maximum functionality, or as an extra protection against clogging, a grinder can be installed before the pump.

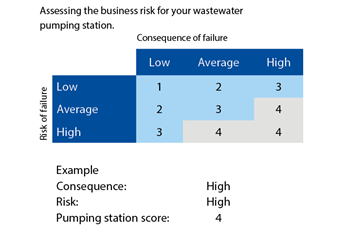

When deciding whether your pumping station needs a grinder or not, we recommend assessing your business risk (see table).

First, you need to determine the risk of failure. It depends on the design of the pumping station, the hydraulic load, the impeller type, and the expected rag content. Then, you have to look at the consequences of failure focusing on an acute overflow. Will it flood local residences (private or commercial), pollute a river or water table, or cause major access problems (for example by blocking a road)?

When working with construction of new pumping stations, you also need to consider future challenges and the risks they will bring.

When you choose to work together with Sulzer, we can use the assessment model shown above to help you choose the right combination of grinders and the best-in-market wastewater pumping equipment to reduce the likelihood of any system failure.

Take advantage of our expertise

David Walters

Business Development Manager – Domestic & Commercial / Dewatering