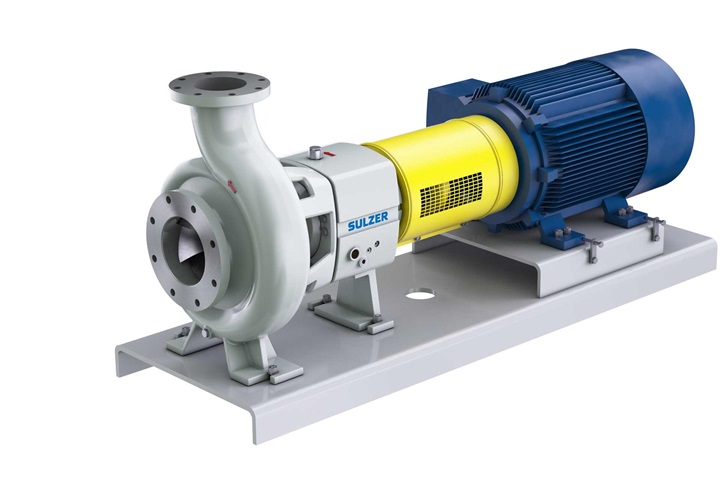

- The highest available efficiency on the ANSI process pump market providing clear savings in energy consumption:

- Exceeds the requirements of all environment (ECO) directives as well as the energy efficiency targets for pumps globally

- Maximized reliability thanks to improved shaft sealing conditions and heavy-duty bearing unit

- High standardization, easy installation and robust construction equate to reduced maintenance and operating costs

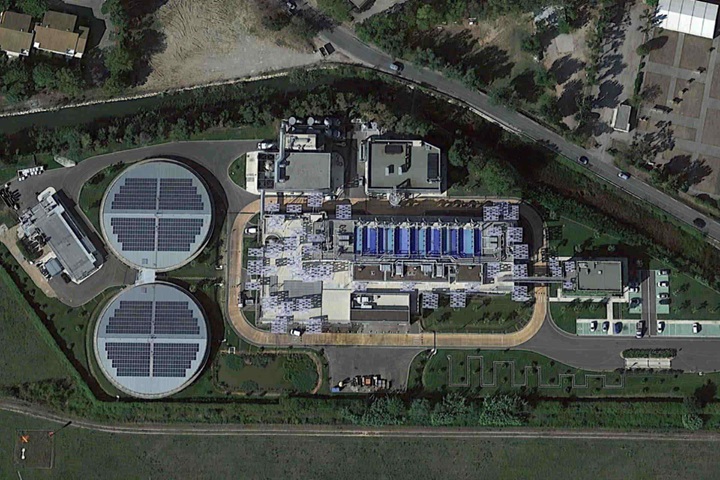

- The CPE pump uses NSF61 and NSF37 certified materials.

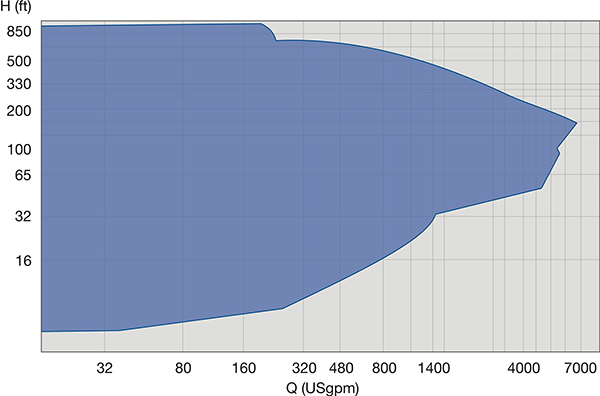

CPE ANSI process pumps range (ANSI/ASME B73.1)

Revolutionary hydraulics and high efficiency offer the lowest life cycle costs

CPE ANSI pumps are specifically designed to exceed the strictest energy regulations for all industries as well as the requirements of ASME B73.1. With revolutionary hydraulics and high efficiency, they offer the lowest life cycle costs.

- Clean and slightly contaminated liquids

- Viscous liquids of up to 3'000 cSt

- Fibrous slurries of up to 6% consistency

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

In the name of efficiency – the new CPE ANSI pump range

Main design features

- State-of-the art hydraulics ensure optimum capacity with low net positive suction head required (NPSHr)

- Optimized seal life thanks to improved sealing chambers and innovative balancing holes

- Trouble-free Sulzer mechanical seals

- Heavy-duty rigid bearing units ensure long bearing life and leakage-free construction

- Modular design reduces the spare part inventory cost

- Quick and easy installation

Key characteristics

| Capacities | up to 1'650 m3/h / 7'000 USgpm |

| Heads | up to 275 m / 900 ft |

| Pressures | up to 27.5 bar / 400 psi |

| Temperatures | up to 260°C / 500°F |

| Maximum speed of rotation | up to 3'000 rpm / 3'600 rpm |

Documents

Brochures

-

CPE process pumps – efficiency by designpdfLanguages:

-

Service kits for CPE ANSI pumpspdfLanguages:

-

Fast delivery of ANSI process pumpspdfLanguages:

-

Sulzer ejector for primingpdfLanguages:

-

Sulzer heating jacket conceptpdfLanguages:

Applications

-

BiofuelsBiofuels from renewable sources show great potential as sustainable transportation fuel. Based on our experience in demanding processes, we work with customers to develop advanced pumping, mixing, and distillation solutions for the production of biofuels, from pilot to commercial-scale installations.

-

BiochemicalsBiorefineries can rely on us to develop advanced pumping, mixing, and separation solutions for the production of biochemicals, from pilot to commercial-scale installations. We have broad experience in the processing of renewable raw materials and chemical processes.

-

OleochemicalsOleochemical production involves demanding separation and purification processes to produce intermediates and end-products with the desired purity. As a pioneer in the oleochemical sector, we have been supplying our separation technology equipment, plants and expertise in the oleochemical sector for more than 35 years.

-

Pulp, paper and boardSulzer is the world leader in innovative, reliable, and proven pumping, agitation and mixing solutions for the pulp and paper industry. Our deep process and application knowledge is based on long-term close co-operation with the producers, machinery suppliers and engineering companies.

-

Sugar, starch and sweetenersEfficient production of sugar, starch and sweeteners puts high demands on the processing equipment. Thanks to many years of experience and comprehensive process know-how, Sulzer offers a wide portfolio of innovative process pumps, special pumps, mixers, agitators, compressors and aerators for these industry sectors.

-

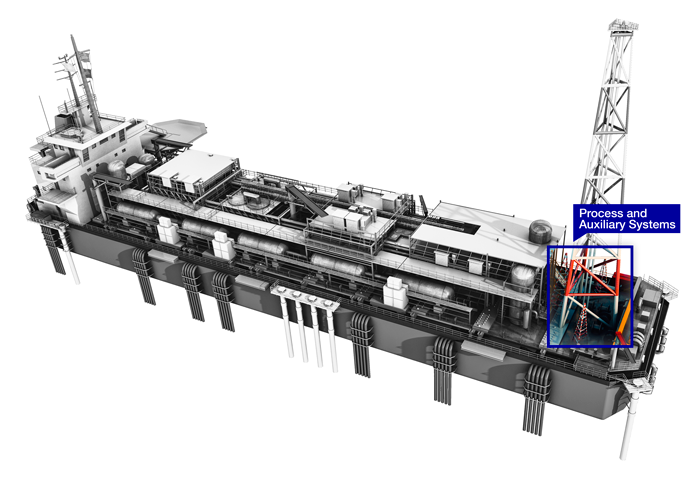

Auxiliary applicationsThe complex processes performed on a typical FPSO rely on the performance of dozens of pumps handling a variety of liquids under widely varying process conditions.

-

Mine water managementSulzer offers a comprehensive portfolio of pumps and process equipment for abrasive and corrosive environments in mine water management applications.

Related links

Products, services and news

-

Sulzer launches IEC-compatible CPE process pumpDecember 14, 2021A few years ago, Sulzer launched the energy-efficient CPE ANSI (American National Standards Institute) centrifugal pump range. Now, responding to the market demand, Sulzer provides an IEC (International Electrotechnical Commission) compatible range of the pump.

-

Sulzer to supply pumps and mixers to the new bioproduct mill in Kemi, FinlandMarch 24, 2021Metsä Fibre, part of the Finnish forest industry company Metsä Group, and Sulzer Pumps Finland have signed an agreement for the supply of process pumps, medium-consistency pumps and mixers for the main processes of the bioproduct mill that will be built in Kemi. The delivery will include several hundred devices.

-

Sulzer launches new CPE end-suction single-stage centrifugal pumpJune 05, 2018Sulzer has once again broken the conventions in the name of efficiency. The new CPE ANSI process pumps are specifically designed to exceed the strictest energy regulations for all industries as well as the requirements of ASME B73.1. With revolutionary hydraulics and high efficiency, they offer low life cycle costs.

-

Agitators, dynamic mixersSulzer SALOMIX™ and Scaba mixing and agitation technology offers a wide range of products for industrial applications. Side-mounted horizontal and top-mounted vertical agitators, dynamic chemical mixers, and tower and tank flow management products guarantee effective mixing and agitating processes.

-

Pumps servicesReliable and efficient pump operation is critical for your business. Therefore you need a service partner that can respond fast and flexibly. Our pump services are second to none and provide solutions that help you to improve your processes and business performance.

-

Original pump spare partsOriginal spare parts machined to the correct tolerances and clearances give a perfect fit first time, every time. Our commitment to continuous improvement often allows us to supply parts with improved features, thus enhancing performance, extending equipment life, while reducing maintenance costs.

-

Service kitsWhen your equipment needs to be repaired you shouldn’t have to worry about spending valuable time searching for the right parts – or even worse, finding out that some small but vital parts are missing. With Sulzer service kits you get everything you need in one package.

-

Sulzer mechanical sealsSulzer mechanical seals are strong by design and have been proven very reliable in various pumping applications.

-

Ejector for pumpSulzer ejector is suitable for all horizontally installed pumps. It offers an easy solution for enabling fast, reliable and fully automated priming for retrofitting existing or new installations. It also includes a full automation package.

$name

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

CPE heating jacket

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

To view the integration, please enable Targeting Cookies.

Open Cookie Settings

Case Studies and articles

-

Pumping equipment in phosphate fertilizer processesPumps are at the heart of phosphate fertilizer production, and correct equipment selection that takes into consideration hydraulic design, materials of construction, application knowledge, duty point and maintenance regime are critical to achieving reliable long-term pumping operation and maximum plant production. Read the whole article.

-

Energy efficiency of pumping systemsPumping systems account for more than 20% of the world’s electrical energy demand, and in certain industrial plant operations they can be responsible for between 25% and 90% of the energy usage. Improving the energy efficiency of the pumping system will reduce production costs and support green credentials. Read the whole article.

-

Supporting sustainable fuel productionSulzer is at the forefront of engineering excellence and quality, delivering best-in-class solutions to support companies in important growth industries, such as biobased, renewable energy production. Understanding precisely what customers need, as well as maintaining the highest standards in manufacturing and service has led to many significant project wins, not least the collaboration with Inpasa, Latin America’s largest producer of corn ethanol. By the end of 2024, this partnership is anticipated to have grown to the delivery of almost 2’000 pieces of equipment, including pumps, sealing systems, agitators and static mixers across six production plants in Brazil.

-

Case studiesWherever fluids are pumped, mixed, controlled or applied, we are there. See how our solutions create value for customers and learn how we can make your pumping and mixing processes more efficient and profitable, safeguarding your production and ensuring lasting reliability.

Talk or write to our experts to find your best solution.