- Designed to deliver constant capacity with viscous fluids and shear thinning non-Newtonian fluids

- Selected drives and gearboxes with many low speed options are available, to reduce pump wear

- Compact for space saving, can be installed vertically or horizontally and run in either direction

- Competitively priced process pump with integral direct drive and gearbox, baseplate optional

PC transfer pump

Consistently high performance: value for money

Sulzer’s competitively priced transfer pump, with close coupled drive and gearbox. Options for vertical or horizontal installation, baseplate and flanged or square inlet, this product has a small footprint, useful where space to install is tight and is available in low to high flow configurations.

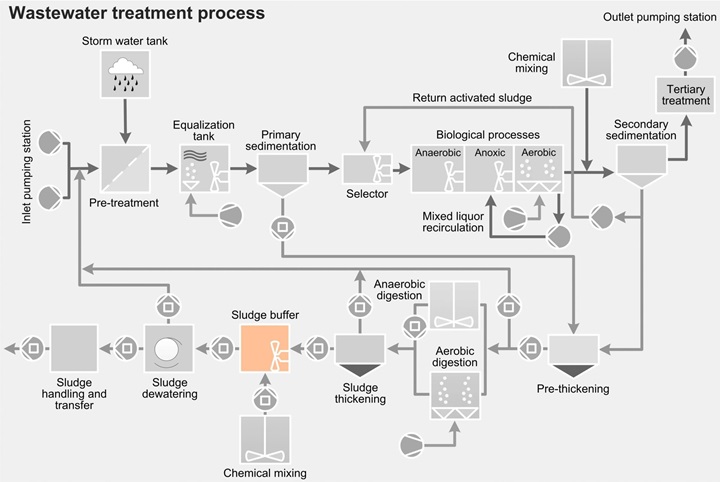

- Sludge handling and transfer

- Municipal and Industrial effluent

- Shear sensitive processes

- Shear thinning slurries

Main design features

- Materials of construction, available in cast iron or stainless steel, with a choice of rotor and stator materials to suit individual applications e.g. hard chrome plated rotor or natural rubber stator.

- Robust drives, specially selected drives and gearboxes for longer life. Options include electric motor drive units supplied as overhead vee belt driven, direct-coupled or variable speed drives with mechanical variable speed or frequency inverter.

- Low running speeds, reduced wear for a longer working pump life which extends the periods between routine maintenance. Important in abrasive applications.

Key characteristics

| Capacities | Up to 440 m3/h / 1,900 US gpm |

| Pressures | Up to 24 bar / 350 psi |

| Temperatures | -10 up to 100ºC / 14 up to 212ºF |