-

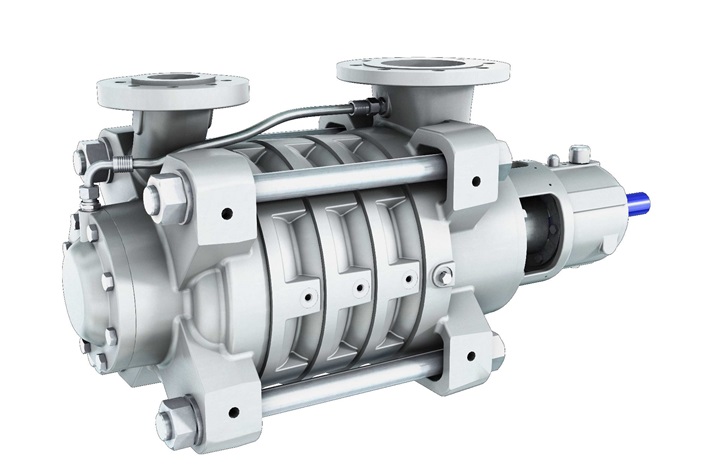

HPT high pressure barrel casing pumpThe HPT is a pump specifically designed for boiler feed applications in thermal power stations. The pumps are optimized to provide high-efficiency operation over an extended period of time, thus reducing operating and maintenance costs.

-

HZB double suction volute pumpThe HZB is a horizontal, radially split, single stage, double suction, centerline mounted pump. The HZB pumps are ideal for use in arduous industrial applications for handling clean, cold or hot liquids as well as for safety-related services in nuclear power stations.

-

SJT-CWP vertical cooling water pumpThe SJT-CWP are "engineered to order" large flow vertical pumps for industrial pumping needs and sump design, with semi-open or closed cast impellers available in sizes starting from 350 mm (14") impeller diameter and nq 75 (Ns 3'870).

-

SJT vertical pumpSJT pumps are typically used whenever a liquid needs to be pumped upward from ground water tables (deep well pumps), manmade underground storage (caverns) or open bodies of liquid. Fully updated hydraulics and mechanical designs make the SJT highly efficient, cost- effective, and low-maintenance.

-

SMD axially split casing double suction pumpThe SMD water pumps are available as standard and configured pumps to meet the demands of different water applications. With a best-in-class hydraulic design, the SMD pumps can take on challenges in raw, clean, sea and brackish water applications. The clean water pumps have ACS and NSF 61 drinking water certifications.

-

AHLSTAR A process pump rangeAHLSTAR A end-suction single-stage centrifugal process pumps are used for demanding industrial applications to ensure process reliability, high efficiency and low operating costs. The pump exceeds the requirements of ISO 5199.

-

ZE/ZF end suction pump rangeThe ZE/ZF are ideal pumps for arduous industrial applications handling clean, cold or hot liquids, including hydrocarbons and light chemicals.

-

MBN multistage ring section pumpThe MBN pumps are ideal for use in high-pressure applications. They have a big variety of nozzle position options, thus providing flexibility during installation and simplifying the piping design.

Ideal supplier for power generation

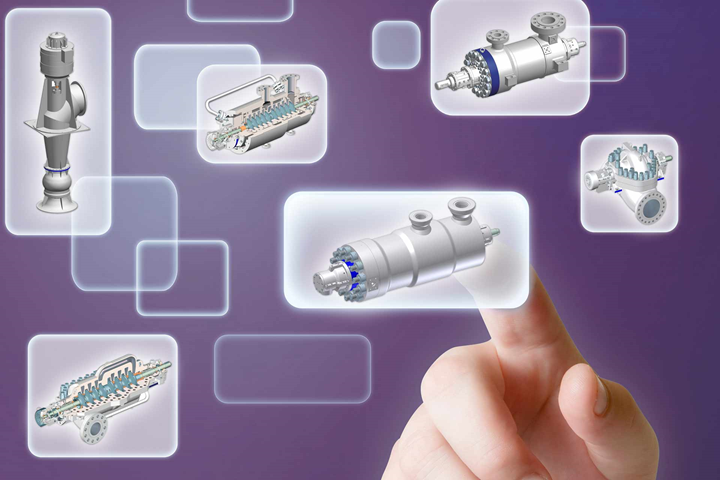

One supplier for all pump applications

Pump selection

Selecting and specifying each of these pumps can have a big impact on overall project and plant performance. Pumps are a significant capital expense, so there is inevitable pressure to keep up-front costs down. At the same time, efficiency differences of just a few percentage points in large pumps can quickly translate into meaningful changes in operating costs. Furthermore, it is vital that each unit is properly matched to its power source and duty requirements because the performance of every pump varies across its operating range.

Then there’s reliability; many pumps will be in continuous operation all the time the station is generating power. They need to cope with demanding workloads with long periods between maintenance interventions. When they do require attention, it is vital that critical parts can be repaired or replaced quickly and with minimum disruption to operations.

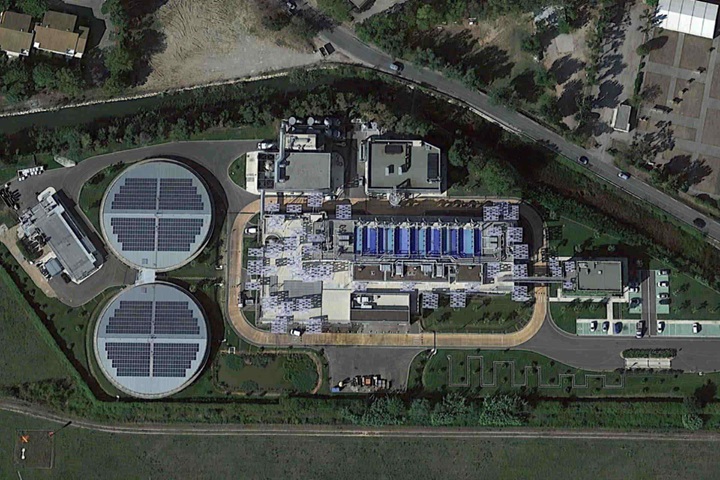

Sulzer has been developing, designing, building and supporting pumps for power station applications for decades. The company’s pumps are used in almost every type of power plant, including nuclear, solar, gas-fired and biomass facilities. As such, it is the preferred supplier for some of the world’s largest and most demanding projects. Take the example of a major new project recently completed in Europe.

Many requirements, one supplier

The plant, commissioned in 2018, is a 1.3 GW thermal power station built using the most advanced combustion and power generation technologies. For this project, Sulzer was selected to supply a total of 38 essential pumps for use across the facility. The list included five HPT type boiler feedwater pumps, five HZB booster pumps, five SJM circulating water pumps, one SJM makeup water pump, four SJT condensate extraction pumps, two STR sea water desalination feed pumps, four SMD closed-cycle cooling water pumps and an additional twelve auxiliary service water pumps.

A key part of the customer’s decision to award the contract in this case was Sulzer’s ability to offer higher efficiency than competitors across both the boiler feed and circulating water pumps. The SJM makeup water pump in particular is capable of delivering 48’000 cubic meters of water per hour.

To ensure the products met the customer’s demanding expectations, Sulzer pump experts worked with the project engineering contractor to custom-design each unit to meet precise duty-cycle requirements. That required close collaboration between the customer and Sulzer’s design and manufacturing specialists in Europe, the USA and China.

In parallel, Sulzer worked closely with electric motor manufacturers to select optimum motors to match the pumps. The highly efficient impeller and hydraulic designs used by Sulzer frequently allow a smaller motor to deliver the required level of performance, and the overall efficiency of the system requires all elements of the pump package to be perfectly matched.

Designs for all applications

Sulzer’s comprehensive product offering for the power generation sector includes auxiliary pumps, all of which perform important roles on-site. As with the larger assets, matching performance to the application is equally important and Sulzer’s auxiliary pump service ensures that every pump is correctly specified for each task.

The vast majority of the pumps were manufactured at Sulzer’s production facility in Suzhou, China with deliveries timed to meet the requirements of the complex construction schedule. Sulzer specialists helped the contractor’s technical staff with installation as well as commissioning, and also provided operation and maintenance training for power station personnel.

For the customer, working with a single, experienced provider ensured that they received highly efficient pumps tailored for their intended applications, while the close and effective working relationship simplified procurement and communication. The power plant is now playing its part as a core element of the country’s energy infrastructure.