First 13E2 inspection in Russia

Sulzer expands its service offering

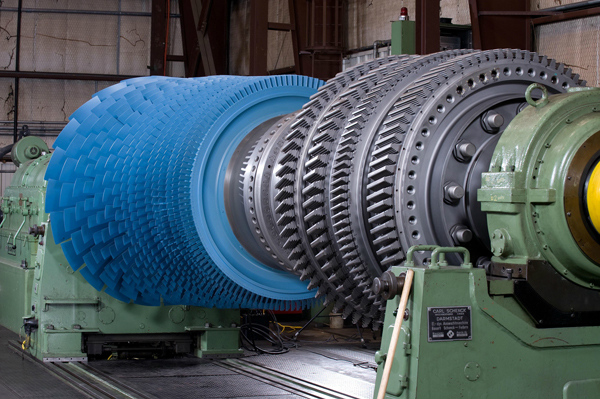

We successfully completed the C-inspections of two Alstom 13E2 gas turbines under a long-term service agreement with one of our Russian customers in the power generation sector. No work of this level of complexity had been performed on this type of machine before.

The complete and complex overhaul of these heavy-duty turbo sets undoubtedly demanded extensive technical expertise. Exemplary teamwork between Sulzer Turbo Services Russia and the Venlo Competence Center for gas turbine services in the Netherlands ensured that our entire know-how was optimally utilized to the customer’s full satisfaction. Close communication with the customer ensured that every step in the process was aligned.

Preparation is key

The successful execution of a major inspection on site is all about preparation, even more so if the project is a first. Our experienced field service teams in Venlo and Moscow teamed up early on to tackle that mission. Joint visits to the site were made to effectively collaborate with the customer to establish the exact strategy.

Scope of work

The work included disassembling the gas turbine, compressor and generator casings, as well as rotor extraction, replacement of the combustion chamber parts (AEV burners, burner lances, zone 2, all zone 1 segments) and parts of the hot gas path (blades and vanes of stages 1-3, stator and rotor heat shields). The scope of work also included fact findings for the main turbine components, including non-destructive testing (NDT), checking auxiliary systems, including the excitation system and generator protection system, and performance of commissioning.

Both units were successfully taken back into operation. The total duration of the project was over three months and involved around 100 people in two shifts. That made even the accommodation and daily transport a challenge.

Oleg Shevchenko, General Director of Sulzer Turbo Services Rus.

“We are proud to be the first company in Russia to perform this level of inspection on Alstom 13E2 gas turbines. This was possible because we worked systematically on enhancing our competencies and because of the excellent cooperation between the Sulzer team and our customer’s team. The long-term service agreement for maintenance of the gas turbine units (GTU) at the power station is multi-year, and we will continue to improve and localize our field service, repair and manufacturing of parts,”

Outstanding team effort

Sulzer’s Gas Turbine Services Business Unit handles major scale heavy-duty gas turbine outages on a frequent basis. Sulzer’s Moscow Service Center alone has handled 11 major and 19 minor and medium outages in 2019, and Venlo Service Center has completed 25 field service events globally, of which three have been major overhauls, so far. The LTSA (Long Term Service Agreement) with the client is held by Sulzer Russia and therefore the contract and project management were handled by Sulzer in Moscow, with Ignat Shabalin as the main project manager. The Venlo Service Center supported the project with sourcing, purchasing and engineering tasks.

Director of the customer's branch

“Long-term service maintenance of gas turbines allows us to solve the task of keeping the main generating equipment of the power plant in operative condition with no necessity of searching for and selecting the service partner. The inspections, performed by Sulzer, represent another step in the history of our cooperation, we are glad to have the first major inspection of 13E2 machines completed in Russia, at our power plant and with our cooperation.”

Key figures

Alstom GT13E2 gas turbine:

- overall length: 11.1 m

- diameter: 4.2 m

- total weight: 315 ton

- weight of rotor: 82 ton

- 21-stage compressor, 48 burners, 5-stage turbine

- 176 MW (ISO), 3’000 rpm

Alstom generator:

- overall length: 12.8 m

- total weight: 230 ton

- weight of rotor: 40 ton

Your contact

Services Division

Sulzer Management Ltd