- Innovative solutions tailored to customer needs

- Minimized downtime

- Exceptional industry, process and equipment experience

- World-renowned engineering expertise

- Access to advanced repair technologies that add value

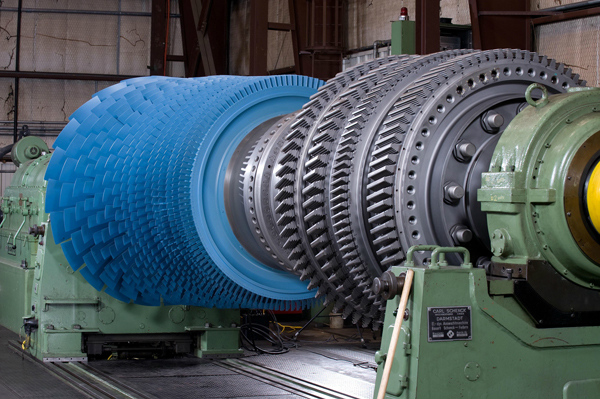

Sulzer Turbo Services, Venlo

Your leading provider for turbomachinery services

- Repair and refurbishment of all types of rotating equipment, regardless of the original equipment manufacturer (OEM)

- Field services available 24/7 with experienced engineering teams at your disposal

- Service Center for turbomachinery including, gas turbines, steam turbines and compressors

- Ad-hoc services or long-term service agreements

- Laser welding, submerged arc welding, precision 3D measurement

Turnkey services for gas turbines, steam turbines and compressors ensure that the Venlo Service Center is a one-stop-shop for turbomachinery.

Turn-key compressor overhaul (axial, centrifugal, integrally geared)

Complete machine inspection, full NDT including material analysis, distortion analysis using latest 3D inspection technologies, impeller repairs, shaft repairs, impeller and component design, fabrication and replacement, application of specialized coatings as well as balancing.

Full-scope steam turbine overhaul

Complete rotor overhaul including de-blading, machining, modifications and re-blading. Complete casing overhaul including de-blading, machining, refurbishment, re-blading. Complete casing repairs including design modifications, groove re-machining, installation of erosion protection rings and seal replacements.

Steam turbine component repairs

Removal of damaged areas by cutting/grinding affected material, applying a protective Stellite overlay or Stellite insert by laser welding.

Gas turbine services

Hot gas component repairs, turbine blades and vanes refurbishment, combustors, fuel nozzles, large rotor lifetime assessments and lifetime extensions including low speed balancing.

| Gas Turbines | Steam Turbines |

Compressors |

|

Independent alternative to OEMs |

Industrial steam turbines up to 75 MW, impulse and reaction designs |

Axial, centrifugal or integrally geared |

|

Repairs and improvements for blades, vanes, combustors, and fuel nozzles |

Complete rotor overhaul |

Vertical/radial or horizontal/axial split units |

|

Rotor lifetime extensions |

Complete casing overhaul |

Turnkey overhaul for rotor and stator |

|

New parts manufacturing |

Spare parts design and fabrication | Spare parts design and fabrication |

Capabilities

Offering 4’000 m2 of floor space and a 120-tonne cranage capacity, the Venlo Service Center can service almost any rotating equipment in-house. Consequently, the facility is a trusted partner of operators in the industrial, waste-to-energy, oil & gas and chemical sectors.

Component assessment, inspection and repair

- Condition assessment & complete NDT incl. X-Ray

- Metallurgy assessments

- Leading edge restoration, overlay or patch repair

- Stellite inserts with laser fusion

- Tip restoration by laser welding

Rotor Assessment, Inspection, Repair

- Mechanical and electrical runout measurements

- Rotor straightness / distortion analysis

- Condition assessment and NDT / crack testing

- Rotor repair / re-machining / upgrading

- Bearing repair

- Seal replacement

- Low speed balancing

Casing assessment, inspection and repair

- Casing distortion analysis

- Reverse engineering / mechanical design

- Repair design

- Casing repairs

- Assembly clearance measurements from 3D scanned assemblies

- High accuracy 3D scanning

- Material analysis and selection

- In-house engineering and design

- Machining, welding, assembly, heat treatment, NDT

- Manufacturing of new parts

The following certified management systems are implemented to ensure the highest quality standards:

- NEN-EN-ISO Certification 9001:2015

- NEN-EN-ISO Certification 14001:2015

- NEN-EN-ISO Certification 45001:2018

- SCC** Petrochemicals 2017/6.0

Your service center