A place to engage

Wildlife Garden in Manor Mill Meadow

As part of our health and wellbeing program, Sulzer Pumps UK maintains a 4’900 m2 garden with the aim of providing employees with a space where they can reconnect with nature and spend time in a nearby area that is mindfulness prone. All 470 employees have access to the garden. In 2021, we installed additional benches upon recommendations from employees. The benches were made of waste wood and the remaining chippings were used to pave the paths.

Sulzer technology decarbonizes the power sector

SaskPower’s Boundary Dam Unit 3 is a 115 MW coal-fired power unit located in Saskatchewan, Canada and using a carbon capture system with internals and packing from Sulzer.

Up to 90% direct capture of CO2 emissions

This enables the direct capture of up to 90% of the CO2 emissions. In total, 4,256,840 tons of CO2 have been captured and sequestered since start-up (source: SaskPower Blog - BD3 Status Update: January 2022 saskpower.com.).

The captured CO2 is sent deep underground to enhance oil recovery (EOR) given the important oil & gas fields present in the region. It utilizes CO2 to maximize the removal of oil from reservoirs. Some CO2 is also permanently sequestered in a deep saline aquifer at the Petroleum Technology Research Centre (PTRC)’s Aquistore facility. As the world needs to decarbonize its main emitting processes, namely power, to reach net zero by 2050, disused coal fired plants could address the needs by retrofitting the existing plants with Sulzer technologies.

Enabling circularity

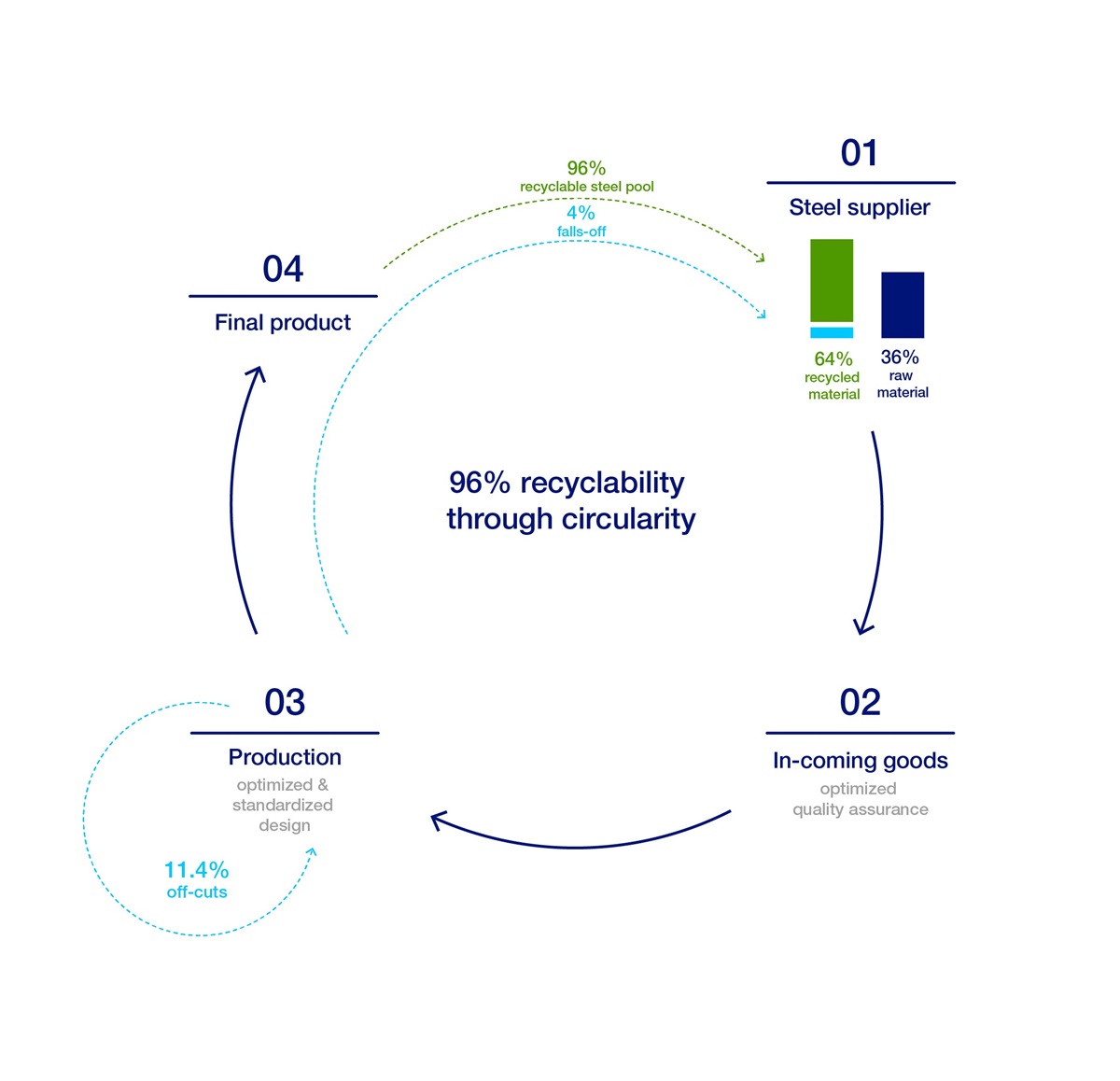

96% recyclability through circularity

In Chemtech India and China, our teams focused on minimizing the waste generation through an optimized and long-lasting quality assurance process jointly developed with our metal suppliers. During the operations, actions on standardizing the design led to less off-cuts and falls-off. All of them were either reprocessed in our own operations or sent to our suppliers to be remelt and recycled for the next batches. This means that ultimately, more than 96% of the supplied metal ends in our final products that are themselves recyclable. This was achievable thanks to a long relationship with our supplier and the strong engagement of our operational excellence teams to optimize our processes.