- Closed-loop system

- Single signal-based control system

- Modular-based solution with 9 system modules

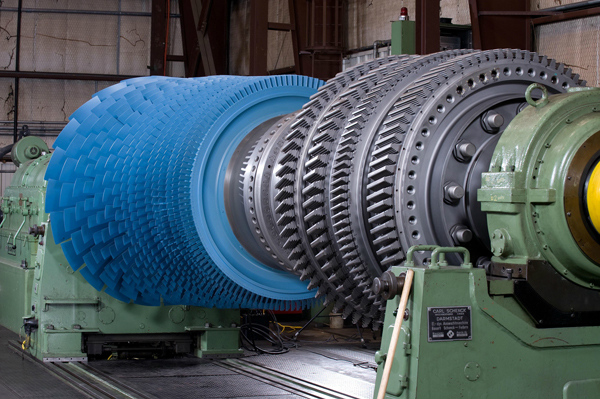

Sulzer CATS- NOx reduction & Optimizing Gas Turbine performance

As countries work towards a more sustainable future, emissions regulatory guidelines are imposed on carbon intensive industries, including thermal power generation. Governments around the world are introducing new emissions standards to improve air quality. A key aspect of this effort is minimizing nitrogen oxide (NOx) emissions from gas turbines. For operators, especially those using legacy equipment, attaining these new emissions standards means investing in their equipment. To complete this while guaranteeing power generation uptime, improving efficiency and securing cost-effective operations is a delicate balancing act. Carbon pricing, rigid standards and fines for non-compliance are being introduced across Asia to limit the release of greenhouse gases (GHG) into the atmosphere. Both Japan and South Korea have introduced mandatory national caps and emissions trade schemes for GHG in the 2010s.

Maximum performance with precise dynamic calibration

Sulzer has developed a bespoke combustion auto-tuning solution (CATS) - which reduces emissions and secures efficiency by balancing key operational parameters. Consequently, operators have a cost-effective, dynamic solution to meet the latest NOx standards. CATS provides real-time, dynamic closed-loop control of the combustion process to reduce NOx emissions by balancing parameters within the gas turbine.

While auto-combustion tuning has been available for more than a decade, Sulzer CATS is closed-looped, enabling the dynamic balance of four key operational parameters with high precision:

- Emissions

- Combustion dynamics

- Power output

- Efficiency

Closed-loop control offers higher precision compared to auto-tuning systems, which are open-loop. The system also promotes overall operational efficiency while reducing NOx emissions. It is suitable for use with selective Siemens, General Electric and Mitsubishi heavy duty GT models.

- Redundancy design

- Feed-forward plus feedback control

- More than 20 operational data parameters monitored