MaxFlux®

Next generation of hydrotreating

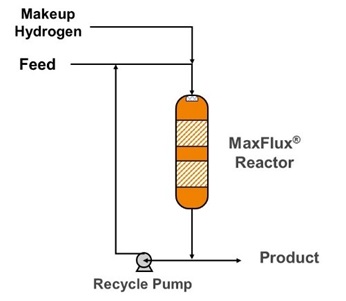

MaxFlux® Advanced Hydrotreating Technology is a novel alternative to traditional hydroprocessing. The hydrotreating reactors operate in a high mass flux mode that removes the mass transfer limitation and eliminates the need for large volumes of hydrogen recycle gas as a quench fluid. Instead, hydrogen is dissolved in a recycle liquid stream to deliver more hydrogen to the reactor and stabilize temperature fluctuations (Figure 1). As a result, installation of MaxFlux instead of conventional hydrotreating offers significant capital cost savings, improved yields, and longer catalyst life.

Over the full range of hydrocarbons, MaxFlux can be installed as a grass roots hydrotreating unit or as a revamp in a pretreat configuration. In pre-treating, the MaxFlux reactor accomplishes most of the necessary hydrotreatment, reducing the demand in the existing conventional reactor, which will then operate in a polishing mode. As a result, catalyst deactivation due to coking in the conventional reactor is greatly reduced.

Benefits of MaxFlux:

• Lower total capital investment

• Lower operating expense

• Longer catalyst life

Contact our team directly