- Cost effective

- Highly reliable

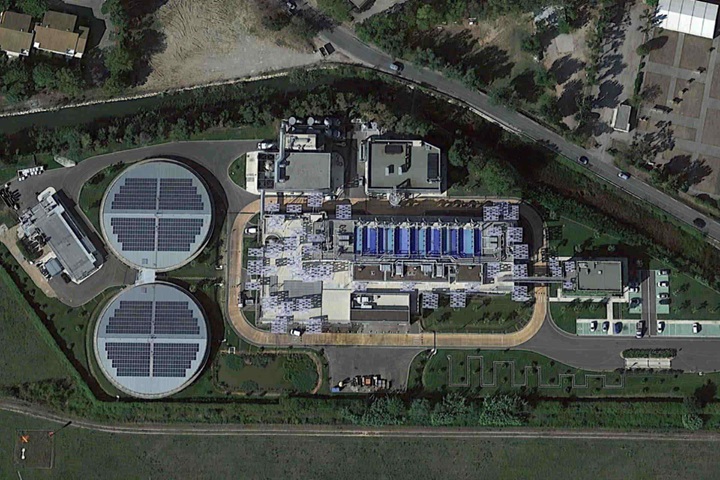

- Efficient solution as ERS booster pumps in SWRO desalination applications

PRF high-pressure booster pump

PRF boosts your savings under pressure

The PRF pump range has been specifically designed to manage clear liquids with high suction pressure. Optimized design ensures maximum pressure resistance and extended lifetime of the pump.

A specific design makes the PRF pump suitable for highly demanding applications such as:

- Reverse osmosis process

- Boiler circulation

- Any high-pressure process application

Main design features

- Back pull-out design: dismantling without disturbing the piping or the motor

- Foot-mounted or centerline-mounted casing depending on size

- Flanges ISO PN 100 to customer specifications: RF RTJ etc.

- Flanges ANSI 600# as an option

- Bearing type: three rolling-contact bearings lubricated by oil with constant level oiler

- Taper roller bearings with high load capability

- Closed impeller with wear ring

- Shaft sealing by high-pressure mechanical seal

- Excellent efficiency

Key characteristics

| 50 Hz |

60 Hz |

|

| Capacities | up to 1’350 m3/h | up to 7’250 USgpm |

| Heads | up to 95 m | up to 445 ft. |

| Pressures | up to 75 bar | up to 1’090 psi |

| Temperatures | up to 200°C | up to 392°F |

| Maximum speed of rotation | up to 3’000 rpm | up to 3’550 rpm |