-

AHLSTAR A process pump rangeAHLSTAR A end-suction single-stage centrifugal process pumps are used for demanding industrial applications to ensure process reliability, high efficiency and low operating costs. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR APT process pump rangeAHLSTAR APT end-suction single-stage centrifugal process pumps are used for demanding industrial applications to ensure process reliability, high efficiency and low operating costs. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR EPP/T high-temperature process pump rangeAHLSTAR EPP/T centerline supported end-suction single-stage centrifugal process pumps are designed to stand high temperature especially in demanding industrial hot liquid pumping applications. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR NPP/T non-clogging process pump rangeAHLSTAR NPP/T non-clogging end-suction single-stage centrifugal process pumps are designed for industrial large solids containing liquid or abrasive slurry applications to avoid plugging. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR WPP/T wear-resistant process pump rangeAHLSTAR WPP/T wear-resistant end-suction single-stage centrifugal pumps are designed for abrasive and erosive pumping applications, such as lime milk and mud, and coating pigments. The pump exceeds the requirements of ISO 5199.

AHLSTAR pumps with maintenance-free dynamic seals

Trouble-free operation in paper mill wastewater treatment plant

The challenge

For the integrated wastewater treatment plant, Norske Skog wanted some dry installed pumps similar to the main process pumps used in the paper mill, with high reliability and ease of maintenance. Superior product technology was a must to avoid any disruption of the process and to optimize the work environment.

The solution

In close cooperation with the customer, Sulzer chose some AHLSTAR APP and NPP pumps for each stage of the wastewater treatment process. In total, more than 50 AHLSTAR pumps were installed. APP pumps with open impellers are handling mill effluents, clarified water and light sludge, while NPP pumps with vortex impellers are running on higher dry solids content (up to 7%) sludge. APP and NPP pumps are equipped with contactless dynamic seals, which eliminate mechanical wear, leakage and the need for sealing water.

Since 1992 our AHLSTAR pumps equipped with dynamic seals have proven to be extremely reliable and economical even in the toughest applications.

Jean-Yves Verguet

Process Engineer Energy & Fluids

Customer benefit

About 450 AHLSTAR pumps are working in the paper mill, most of them with dynamic seals. The dynamic seals are designed for stock consistencies up to 8%, but are also perfectly suitable for all other difficult liquids with a high solids content, including sludge. By using the same type of AHLSTAR pumps with dynamic seals in the wastewater treatment plant, the client can be ensured of equally trouble-free operation. Also, by having the same pumping equipment at both locations, the spares storage and maintenance costs are greatly reduced.

| Liquids | No. of pumps | Pump types | Impeller | Seal |

| High DS sludges (primary, thickened, combined) | 11 | NPP | Vortex | Dynamic seal |

| Low DS sludges (return activated, excess) | 8 | APP | Open | Dynamic seal |

| Others (mill effluents, storm water, treated water, nutrients, acids) | 32 | NPP, NPP-S, APP, APP-S | Vortex, open, closed | Dynamic seal, others |

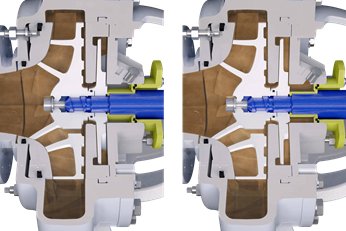

The wastewater treatment plant has a total of 51 AHLSTAR pumps. Most of the pumps are fitted with dynamic seals. The contactless dynamic seal uses an expeller to move liquid back into the volute casing and away from the stuffing box when the pump is running. When the pump stops, the liquid flows back into the stuffing box, creating an elastomeric static seal to prevent leakage.