Mission impossible

28 days for gas turbine repair

Damage assessment

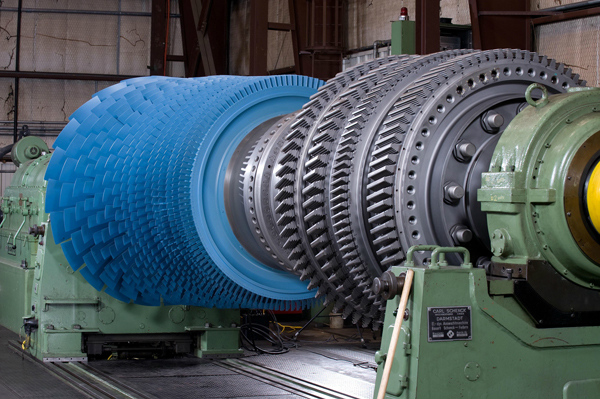

For one Californian municipality, the location of two of its 20 MW gas turbine generators would present a significant problem with corrosion being only a mile of the ocean. In fact, the situation had reached the point where one unit had ingested a stator blade into the compressor and travelled through the turbine.

In this situation, the turbine operator is required to follow certain bureaucratic procedures like consulting the approved suppliers’ list for a company that can repair the equipment in the most cost-effective way. From this, Sulzer received the call to investigate the failure and to complete an overhaul on site. At this point, the extent of the damage was unknown, since the borescope scan had produced limited information.

Sulzer’s engineers advised the turbine operator that the best course of action would be to remove the thermal block (the central rotor assembly and hot gas path components) and have it repaired at Sulzer’s service center in Houston, TX. However, due to the reduced time frame for the repairs, Sulzer offered to supply a replacement thermal block from the same service center.

Tony Dunkle, Area Sales Manager for Sulzer

“Originally there had been approximately 40 days available for the external works to be completed, but due to internal communication delays within the municipality, when the project was finally given the green light, there were only 28 days left to complete all the work.”

Field service expertise

The location of the turbine was very confined. Sulzer’s field service teams worked on site but were only permitted to work during daylight hours. They prepared the damaged thermal block to be removed by a mobile crane, but this would also pose a challenge. In order for the crane to reach the turbine, Sulzer’s team had to build a rail system to move the thermal block from the turbine area to a location where it could be lifted and placed onto a truck for transport to Houston.

Having removed the damaged unit, it was inspected by Sulzer’s engineers and deemed to be beyond economic repair. This means that, without Sulzer’s intervention, the customer would have been looking at finding a new turbine or a new thermal block, most likely from the original equipment manufacturer (OEM). However, the lead time for these components is considerably greater than 28 days.

However, within Sulzer’s inventory there was another thermal block of the same specification that had been partially repaired but was no longer required. The workshop team in Houston was completing the repairs to this thermal block so that it could be installed as a replacement. The scheduling of these two stages was very important because when the time came to lift the damaged thermal block and load it onto a truck, the replacement needed to be waiting nearby, ready to be craned into position. This ensured the fastest turnaround on the project as well as minimizing the cost of craneage for the customer.

Change of use

Quick start units, such as this one, are being used more and more to deal with increased demand on the electricity network. However, starting and stopping a gas turbine several times each day places considerably more stress on the components than they were originally designed for. This means that regular maintenance and periodic inspections become even more important if these units are to remain reliable and efficient.

Combining these demands with an increased risk of corrosion only compounds the problem. In this case, repeated start/stop operations each day means every time the turbine is shut down the air inside cools and condensation forms inside the housing, causing corrosion to form on exposed metallic parts.

Furthermore, in areas where environmental emissions are closely monitored, and the standards particularly stringent, regular maintenance is essential to keep the turbines mechanically sound as well as operating within the statutory limits for exhaust emissions.

Meeting the deadline

Once the installation of the new thermal block had been completed, a few members of the field service team remained on site to assist with the initial commissioning and startup of the gas turbine. However, what really mattered to the customer, Sulzer had made the 28-day deadline and the unit was back online as requested in the original approach.

The project was such a success that the task of inspecting and overhauling the second unit is also being evaluated. This time, further enhancements are scheduled to improve the durability of the unit. The plan is to install another exchange thermal block but with the addition of specialist coatings to prevent corrosion.

This is a preventative action that will improve the reliability as well as the overall service life of the unit. Under the agreements in place, planned maintenance work can be scheduled and the outage of one generator will not be penalized. As such, Sulzer will support the turbine operator to complete the project on time and ensure that the local population continue to have the power they need, when they need it.

Your contact

Services Division

Sulzer Management Ltd