- Inspection

- New coil manufacture or copper re-insulation

- New stator and rotor cores

- New or refurbished commutators

- Repair, refurbishment and remanufacture of all mechanical parts

- Rewinds

- High speed balancing

- Final testing

Falkirk service center

Exceeding your requirements in Falkirk

- AC and DC traction motor overhauls, rewinds, and repairs

- LV motor and generator overhauls, rewinds, and repairs

- Gearbox and other mechanical equipment services, and repairs

- Transformer rewinds and repairs

- Low speed balancing

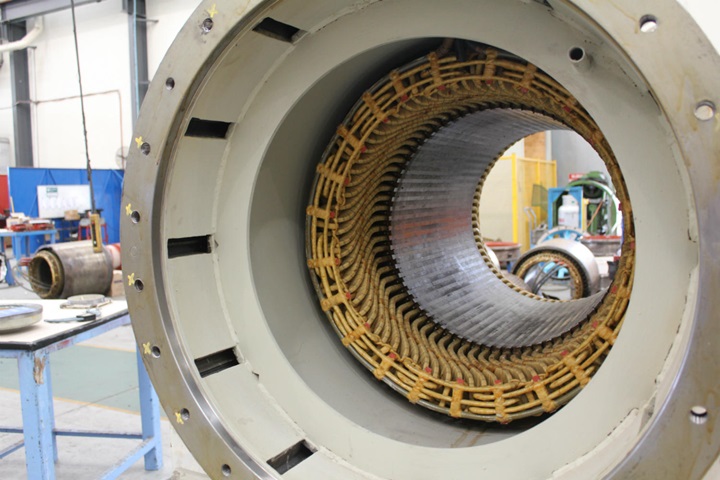

Electrical equipment, high-voltage generators, motors and wind turbines

Sulzer can provide a full range of large rotating electrical equipment services in our workshops or on site:

- Inspection

- Maintenance

- Coil manufacture

- Complete rotor and stator rewinds

- Mechanical repairs

We can also provide re-engineering solutions, power uprating design studies, DC to AC conversions, and long-term maintenance contracts.

Investment and upgrade

Until now, the Falkirk site has used a 1,250 kVA diesel generator that operates through two step-up transformers to provide 3.3 - 11 kV via high voltage switchgear to the test cell. This setup ensures a reliable power source for testing that is not affected by local demand on the power grid.

The new investment by Sulzer will add a 2,000 kVA and a 700 kVA generator to the site that will be synchronized through a 4000A LV switchboard, as well as a new 2,500 kVA transformer, that will double the capacity of the test bed.

2 MW load testing

The original capacity of the service center was 1,000 kW in load testing, of which 800 kW could be used for testing vertically-orientated motors, across a full range of voltages from 400 V up to 11 kV at both 50 and 60 Hz. The installation of the new equipment will increase the load testing capacity to 2,000 kW for horizontally-orientated motors as well an increase in voltage to 13.8 kV. The majority of the equipment tested in the additional capacity will be large, high voltage, AC motors, but the possibility to test DC motors up to 600 V, with a loading up to 800 amps will still remain.

Furthermore, an additional test-bed area is now in place to allow multiple motors to be tested alongside each other. This means that if the testing of one motor needs to be extended, it will not hold up other projects, allowing equipment to be returned to customers even more efficiently.

The new test bed offers customers the possibility of load testing generators using a slave motor to turn the generator and connecting the output to a load bank. In this way, generators that have undergone major repairs can be tested to ensure that they are fit for purpose before they are re-installed and recommissioned.

“In the past, only equipment that had undergone a major repair would have received a full-load performance test. Now, more and more customers are requesting full-load testing following an overhaul, giving them complete peace of mind that the equipment is fit for purpose."

Marc Stuart, Service Center Manager at Sulzer’s Falkirk service center

Improved customer experience

As part of this upgrade project, the test area is equipped with the latest monitoring controls and safety equipment that provide the test engineers with remote visualizations of the sensor readings while protecting them from large pieces of rotating equipment. A customer viewing area is also available, from where owners of equipment can watch and interact with the test engineers to ensure that the entire process is transparent and straightforward.

Certificates

The following certified management systems are implemented at most Service Centers to provide the highest quality standards:

- ISO 9001

- EASA

- Baseefa IECEx

- UL

- NiCEiC

- AEMT

- CHAS

Your service center

Sulzer Electro Mechanical Services (UK) Limited

Lochlands Industrial Estate

FK5 3NS Falkirk, Stirlingshire

Scotland