- Innovative customized solutions

- Minimized downtime

- Extensive industry and process knowledge of our engineers

- Global service network

Sulzer Advanced Manufacturing Center, Johannesburg

Your ideal local service partner

Supporting customers 24/7, Sulzer is dedicated to improving our customers’ pumping processes, operational reliability and high performance of their rotating machinery. We provide outstanding service solutions for leading industries.

- Equipment performance and material upgrades in line with changing process requirements

- Sulzer's global network of spare parts manufacturing centers provides support for additional spare parts

- Management services in association with long-term equipment support contracts

- Reverse engineering and retrofits

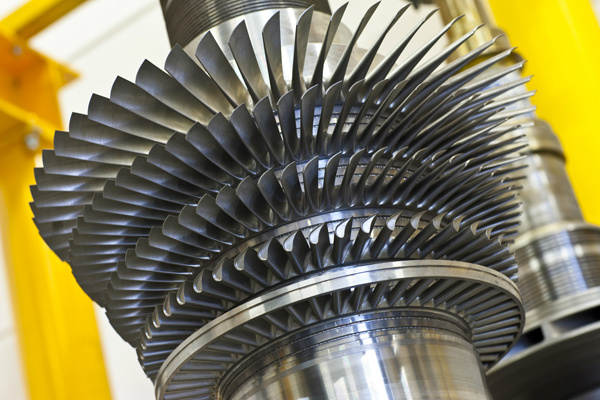

Our comprehensive workshop facility in Johannesburg is fully equipped to overhaul and repair all types of rotating machinery. The office center houses engineering, contract administration and sales staff providing services for a wide range of hydraulic, mechanical and metallurgical challenges. For complex projects, Sulzer’s engineering and technology groups provide the center with industry leading mechanical design and hydraulic development support.

Service expertise

- Repair and refurbishment of all types of rotating equipment (either Sulzer or non-Sulzer manufactured)

- Provision of skilled field personnel for on-site overhauls, installation and commissioning work plus machinery diagnostics and trouble shooting

- Round-the-clock emergency response cover

- Tailored engineering solutions to enhance equipment reliability and effectiveness.

The following certified management systems are implemented to ensure the highest quality standards.

- ISO 9001 (2015)

- ISO 14001 (2015)

- ISO 45001 (2018)

Sulzer Advanced Manufacturing Center, Johannesburg

Sulzer Pumps (South Africa)(Pty) Ltd.

9 Gerhardus Road

1406 Elandsfontein

South Africa