- Conventional low speed design, no gearbox required

- Compact design for excellent rotordynamics

- Barske Type impellers as used in other low flow ranges

- Variable diffuser optimizes operational range

- Shared GSG components reduces spare part inventory

GSG low flow pump

The reliable API 610 solution for low flow services

The GSGLF pump is the only fully compliant API 610 high-pressure pump for low flow applications and the alternative to high speed, OH6 pumps.

- High pressure refinery wash water

- Hydrocarbon closed drain pumps

- Process charge pumps

- Industrial boiler feed water

Main design features

- Barske type impeller and precision machined diffuser ensures correct performance

- Full API 610 11th and 12th edition design

- No gearbox required, pump operates at 2-pole, 50 Hz (3’000 rpm) or 60 Hz (3’600 rpm) motor speed

- Standard is less than 11’000 Nss suction impeller avoiding high values associated with OH6 design

- Optional inducer option to meet client's site limitations

- Suction regions of pump rated for discharge pressure

- Impellers axially retained in both directions as standard

Key characteristics

| Capacities | Up to 35 m3/h / 155 US gpm |

| Heads | Up to 1'800 m / 5'900 ft |

| Pressures | Up to 200 bar / 2'900 psi |

| Temperatures | From -29 °C to +200 °C / -20 °F to +400 °F |

| Flange ratings | 600#, 900#, 1500# and 2500# |

| Maximum speed of rotation | Up to 3'600 rpm |

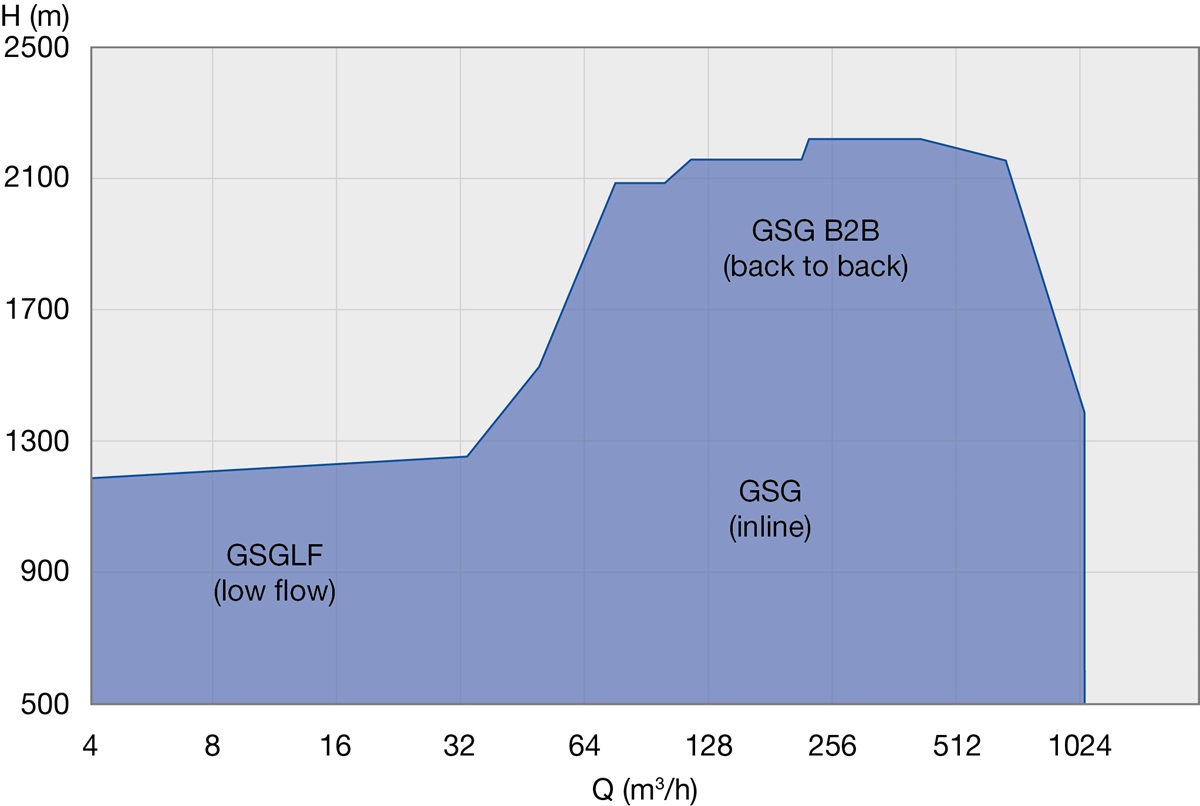

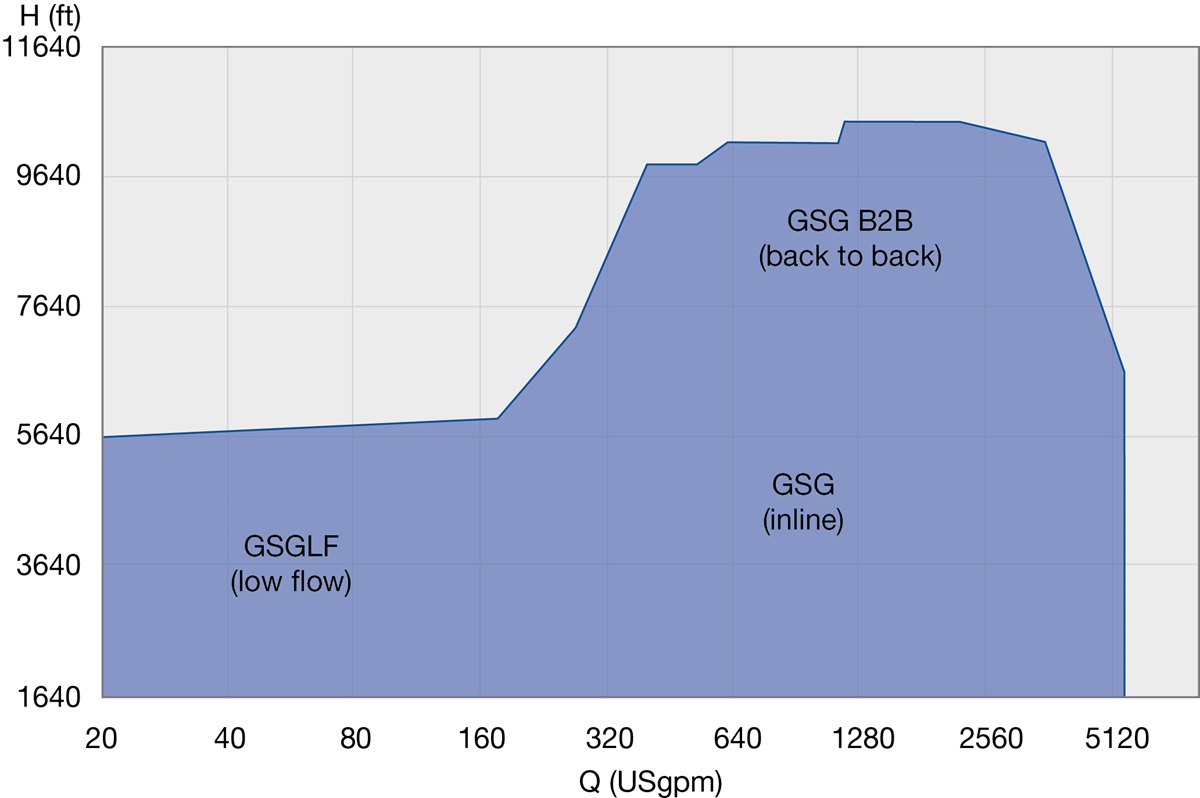

Performance range

Performance range 50 Hz

Performance range 60 Hz