Technical article

Trusted partner for new wood-based processes

Proven expertise

Sulzer is globally specialized in pumping, agitation, mixing, separation and application technologies for fluids of all types. We serve our clients worldwide through customer front-end experts, production sites, and a customer service network that provides qualified services for the entire product life cycle.

The Flow Equipment division specializes in pumping, mixing, agitation and aeration solutions specifically engineered for the processes of our customers. Intensive research and development in fluid dynamics, process-oriented applications, products and special materials as well as reliable intelligent service and performance improvement solutions support the company to maintain its forerunner position in its focus market segments like oil and gas, power, pulp, paper, board, chemicals, water and wastewater.

The main Sulzer competence center with the world’s biggest full-scale research facility for the pulp, paper and board segment and for new process applications based on wood raw materials is located in Kotka, Finland. In addition, we have successful examples of process equipment development projects for novel intermediates like mixed and virgin textiles, agri-waste, and waste bio-mass. Depending on the setting and goals, test runs can be executed for various equipment, velocities, intermediates, and consistencies in our research center in Kotka or at customer’s site.

Thus, the main product platforms for these industries are developed in Finland, where we have strong roots reaching back to the Ahlstrom Pumps era. The main manufacturing units for Sulzer products for these markets are also in Finland, but our global factory footprint covers all main regions.

Strategic and committed partnerships

Deep applications understanding is the key for clever and high-performance suspension transfer and treatment solutions. We are an independent equipment supplier and a trusted application solver, but you can never be strong if you try to work on your own. Our knowhow and product reliability are based on close cooperation with the world’s leading pulp, paper and board producers, machinery suppliers, engineering companies and research institutes.

Textiles and various new cellulosic derivatives offer interesting future opportunities and complement our strong presence and expertise in pulp, paper, board, and hygienic product sectors. The industry is also dedicating resources for developing new ways to process cellulose as well as to create new products from new bio- and agri-based feedstocks.

Forest companies, research institutes and other players in the industry are actively investigating and developing new processes for additional products based on higher-value wood raw material. Such developments are, for example, to replace cotton and fossil-based synthetic fibers like polyester or to produce higher-value carbon products and modified cellulose materials for packaging barriers, coatings for medicines, and nutrients. The pulp, board, tissue and paper segments offer a very interesting and important scope together with new additional bio-based future products. We are committed to this new development.

The knowledge accumulated through committed long-term research and development as well as through mergers and acquisitions has strengthened Sulzer’s pump know-how and further enabled full-scale research for the development of pumps, mixers and agitators. As the home of the following known trademarks we serve the installed equipment base also beyond Sulzer: Ahlstrom Pumps, Scanpump, ABS, Ensival Moret, Serlachius, Enso, API, Sonesson, Gothia, JMW and Warren.

Strategic and committed partnerships and long-term development forums with pilots and demos are of crucial importance for coping with the fascinating future potential.

Extensive product coverage

With our full-line product portfolio, we offer the most eco-efficient product solutions, including products for complete water and effluent treatment applications. We introduce a new product series or a major upgrade to an existing range every year.

- The AHLSTAR pump series has proven performance with stocks and various types of suspensions and especially with high-volume flows and liquids containing a high amount of gas.

- The MCE™ medium consistency pumping systems combine excellent performance with energy savings for the highest pulp mill production rates in the world.

- ZPP low-pulse feed pumps are designed specifically for paper and board machines.

- The MBN multistage pumps cover a range of high-pressure and shower water applications.

- SALOMIX™ and Scaba agitators offer optimum tank and tower mixing results.

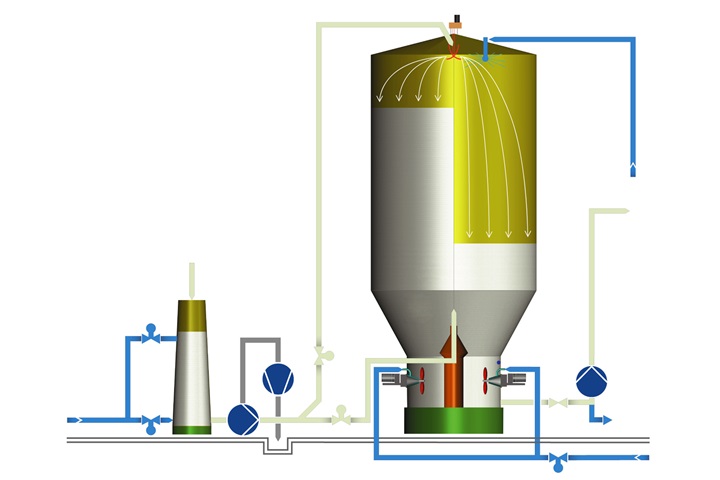

- The TMS tower management system prevents channeling in storage towers, providing unique process advantages.

Sulzer Sense condition monitoring is a unique solution that, in combination with our Sulzer Sense online service, allows you to remotely view the operating status of all the pumps and other rotating equipment at your facility. Wireless sensors attached to the pump measure temperature and vibration in three axes and allow operators to optimize preventive maintenance and enable troubleshooting.

Sulzer is the key equipment supplier for many major recent pulp, paper and board mill investments in countries such as Finland, Sweden and Brazil. For example, Metsä Group’s new Kemi bioproduct mill has almost 600 Sulzer equipment applications in key process positions throughout the main mill departments.

Please also note that the huge-capacity Sulzer MCE™ medium consistency pumping systems, developed and manufactured in Finland, manage the pulp flows through the most modern pulp mill fiber lines in the world.

Contact our expert for more information