Technical article

Buying into a record of kept promises with Sulzer spare parts

With this in mind, the obtaining of spare parts is a crucial decision-making process for system managers. Customers nowadays face a growing array of options, with OEM manufacturers vying for attention alongside a growing network of competitors and imitation products. Cut prices present an eye-catching appeal to cost-conscious operators – but short-term savings do not always represent true value over time.

Sulzer has been developing pumping solutions for the process industry for over 100 years. When purchasing a Sulzer product, a customer buys into a vast network of expertise and knowledge built up over an illustrious history. Expertise and regular advice are available from the moment an agreement is made through to when the pump is retired from action many years later.

Keeping customers up to speed

Continuous and systematic improvement is as vital for spare parts as it is for wholescale pump solutions. Sulzer’s global Customer Support Services network carries out regular mill surveys and energy audits to ensure optimal performance. Experts can help replace ageing spare parts with technologically superior alternatives. Third party suppliers are not aware of the full system setup and thus not able to advise on the most sensible steps forward.

Regular consultations with Sulzer personnel help extend the lifecycle of the pumping systems by ensuring more reliable operation, fewer unexpected failures and lower lifecycle costs. Furthermore, Sulzer provides a full range of inventory management to support customers to manage their stock and to reduce inventory costs, thus giving them more time to concentrate on their core business.

Peace of mind

The uniquely modular approach of Sulzer’s pumping solutions is designed to make operation as convenient and functional as possible. Any maintenance or upgrading can be carried out easily, and the modular structures allow the customers to manage with a clearly lower amount of spare parts. This modular approach does make it fairly easy for competitors to replicate spare parts. But looks can be deceiving – what might seem like a straightforward duplicate can cause incremental damage that may escape detection.

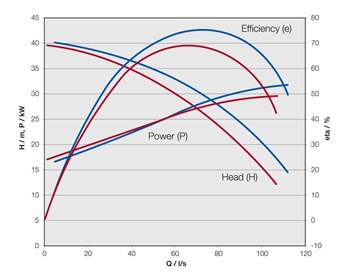

A study analysing the hydraulic performance of the impeller of one of the more reputable third-party suppliers discovered that the part had a major deficiency in its output. In order to achieve the required output, the pump had to be run faster thus using more energy (Figure 1). This added € 2’000 per year in terms of energy cost per part, easily outweighing the € 600 saving made in the purchase price. Aside from poor hydraulic performance, the impeller also had deficiencies in mechanical quality, such as back vanes that were too high and runouts that exceeded tolerances. The manufacturing material was not as described. Sulzer always balances impellers to meet the allowed tolerances, something which is not always the case with third party parts.

Extensive undue vibration placed considerable stress upon pumping performance, while mechanical contact with the casing cover led to higher power consumption. All of this meant there was potential of seizure if left unaddressed. In a separate case, the same manufacturer was responsible for replacing an old pump made by Scanpump (now part of Sulzer). The third party’s replacement pump failed completely, and the customer contacted Sulzer. The pump was delivered promptly and has proved a success.

The important thing to note is that these examples represent some of the best third-party parts available from a comparatively reliable manufacturer. Less-than-ideal performance is one thing, but the worst-case scenario is far more problematic. Pump failure in a slurry mill or sewage works, where potentially corrosive and hazardous materials are being used, can be severely problematic to a vast community and, at worst, fatal.

Long-term trust over short-term gains

The true value of selecting OEM spare parts is evident, and several long-term customers have returned to Sulzer. Two such clients, a major packaging provider and a pulp mill respectively, decided that the technical support they received from Sulzer was unmatched by other competitors, with questions being answered quickly and around the clock when it came to spare parts. A third-party parts provider would simply be unable to match Sulzer’s in-depth knowledge that comes with having designed, constructed and installed all parts of the pump solution. Sulzer’s relationships with other major suppliers are also helpful, as can be seen in two agreements made with global lead companies in the forestry and electrical equipment industry, with the latter partner joining forces with Sulzer for a joint warranty agreement.

Sulzer has been driving industrial processes all over the world for over a century, refining the pumping solutions for the best performance. By selecting Sulzer as the wholescale OEM provider of spare parts, system operators can get the best out of their pumping systems.

Contact our experts

Pekka Salmi

Head AM&S Operations Development Business Unit Water & Industrial