- Methanol Recovery from Biodiesel and Glycerin

- Glycerin Drying

- Biodiesel Drying

- Biodiesel-Glycerin Separation

- Glycerin-Fatty Matter Separation

- Biodiesel Washing

- Biodiesel-water Separation

- Glycerin Refining (to USP grade glycerin)

- Biodiesel Distillation

- Methanol-Water-biodiesel separation (acid esterification)

- Fatty Acids Removal (acid esterified biodiesel)

- Biodiesel/FAME Fractionation

- Glycerin to Propylene Glycol

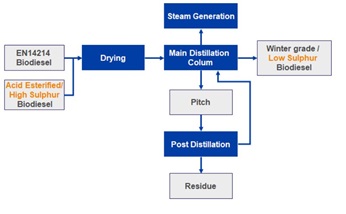

Biodiesel distillation

Ways towards ultra-low sulphur biodiesel

Biodiesel distillation does not only attain the low monoglyceride and low Cold Filter Plugging Point results, the process reduces the Sulphur content at the same time. Sulzer has established a polishing process to assure the distilled biodiesel Sulphur content is less than 10ppm. “Have a peace of mind in your biodiesel quality and conform with the legislation”.

- The highest methanol recovery rate and highest purity recovered methanol

- The best static separation equipment with the lowest investment

- No rotating separation equipment required

- The most efficient recovery and separation process

- Guaranteed performance and long reference list

- Testing facilities available

Biodiesel distillation was originally designed to purify trans-esterified biodiesel, separating components precipitating at low temperature. Through the distillation biodiesel can be used at low ambient temperatures (winter grade biodiesel). Moreover, the colour of trans-esterified distilled biodiesel is enhanced from yellow to near colourless.

The process is applicable for acid esterified biodiesel and pyrolysis biofuel to also reduce or even remove contained Sulphur .

Our distillation plant features:

- Winter grade biodiesel product

- Low Sulphur biodiesel product (for acid esterified biodiesel or other high Sulphur biodiesel)

- Full ISBL, skid supply or customisable scope of supply & services

- High yield of FAME by addition of post distillation (candle evaporator)

- Very low monoglyceride in product

Contact our Bio-based team below